Ingenuity and wisdom, reliable choice - Sany Petroleum coiled tubing injection head

2022.11.10

Sany Petroleum

As the world's leading manufacturer of coiled tubing equipment, Sany Petroleum has developed a new generation of injection head on the basis of summarizing the experience of on-site use, independent research and development, and continuous optimization of performance.

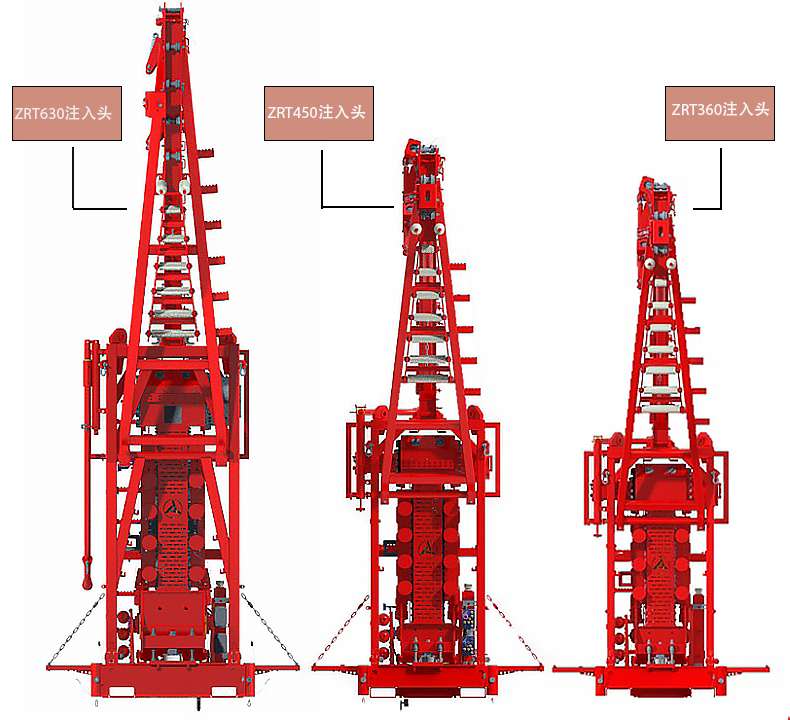

Since the first independent R&D and design of coiled tubing injection heads in 2021, the development of 630, 450 and 360 injection heads has been completed, and each product is customized with ingenuity, and has been widely used in multiple oil and gas field development areas such as Southwest, Northwest, North China, and Northeast China, creating a number of construction records.

As the core assembly of coiled tubing equipment, the injection head can lift and lower coiled tubing, and is an indispensable key component of coiled tubing operation equipment. The injection head developed by Sany Petroleum adopts first-line international brand parts, which can ensure the stability and reliability of the injection head. In terms of design, the injector head has a longer clamping area, a more compact structure, and a patented clamping block for easy maintenance and replacement by the operator.

So what is the good of Sany Petroleum coiled tubing injection head, look down!

Inject head action

The main function of the injection head is to continuously transport the coiled tubing to the downhole for well cleaning and workover, and to recover the coiled tubing smoothly after the operation is completed. During the transportation process, the operator needs to control the length and load of the tubing in real time in order to make judgments on the complex working conditions in the well, so the injection head is equipped with a load cell and a counter.

How the injection head works:

The coiled tubing is guided into the clamping system through the gooseneck system, and the main function of the injection head clamping system is to clamp the coiled tubing and realize the coiled tubing into and out of the well through chain drive. Here we mainly introduce the principles of gooseneck system, fingerweight system and clamping system.

1 How the Injection Head Gooseneck System Works

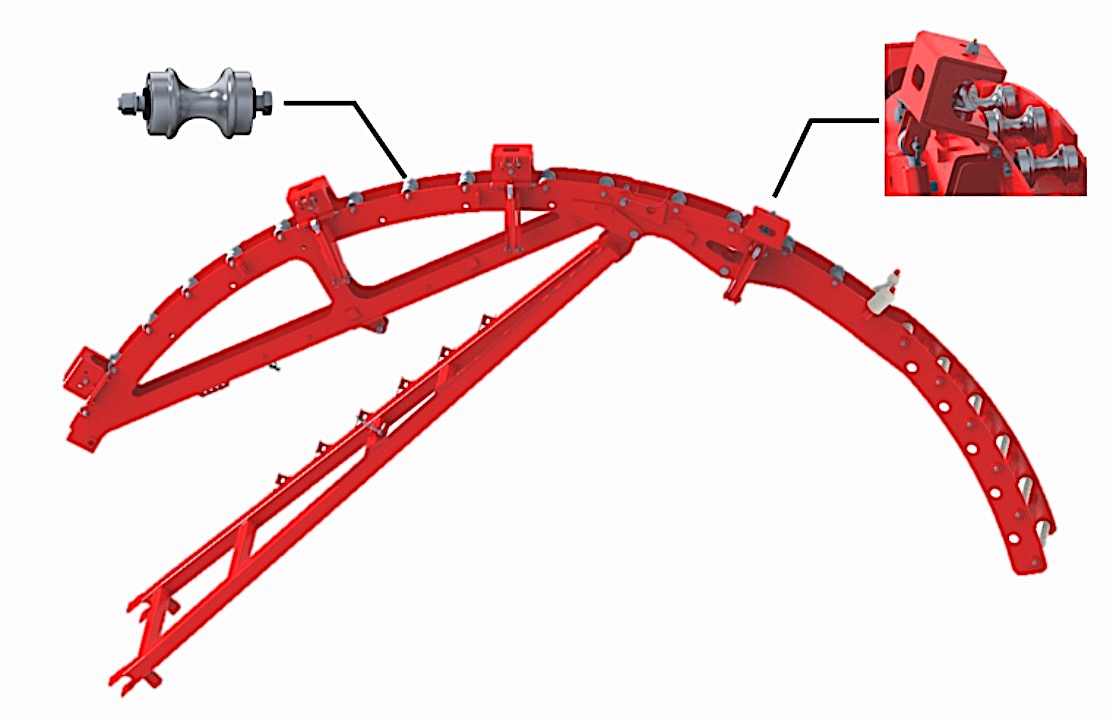

The main function of the gooseneck of the injection head is to guide the coiled tubing into the clamping system, because the coiled tubing is usually made of steel material and has a certain toughness, so the reasonable gooseneck structure can reduce the risk of coiled tubing wear and increase the service life of coiled tubing.

The injection head gooseneck system is generally composed of four parts, namely the gooseneck main assembly, the gooseneck folding assembly, the gooseneck support assembly and the gooseneck hydraulic system. Factors such as overall strength, safety of working at height, and compact structure are considered in the design.

During the construction process, the coiled tubing is from the drum to the gooseneck folding assembly, and the initial positioning is achieved through the opening angle of the gooseneck folding assembly and two nylon guide rollers, and then the precise guidance is achieved through the upper rollers of the gooseneck. Sany Petroleum Intelligent Equipment Co., Ltd. has developed gooseneck with the characteristics of high strength, good stability and long maintenance-free cycle, which provides guarantee for each coiled tubing construction.

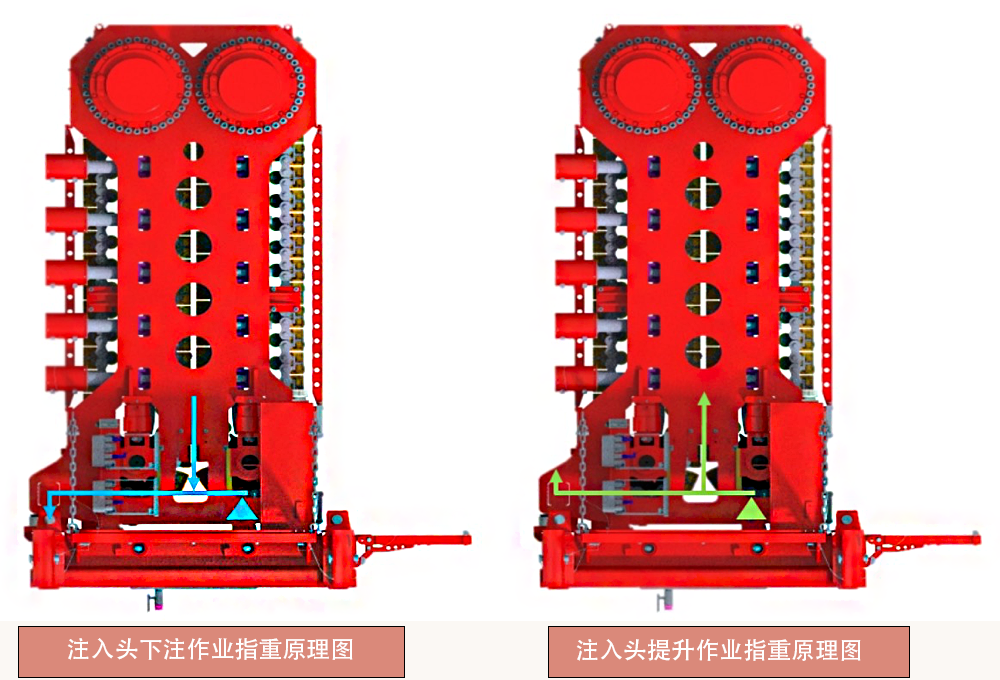

2 How the Finger Weight System Works with Injection Head

The finger weight system parameters of the injection head are one of the most important indicators of coiled tubing operation. During the operation, the coiled tubing will cause real-time changes in the parameters of the injection head finger weight system in the oil and gas downhole environment and working conditions, and the on-site operators will judge the construction situation based on these parameter changes.

In the process of injection head operation, the whole main box and the clamping system can be regarded as a whole, when the coiled tubing betting operation is carried out, the injection head continues to exert downward force on the coiled tubing, because one side of the main box is connected with the base hinge as a fulcrum, the downward force exerted by the injection head to the coiled tubing can be proportionally converted to the position of the fingerload sensor (as shown in Figure 1 below), and then the injection head coiled tubing betting load (pipe weight) is fed back in real time.

When the coiled tubing is hoisted, the injection head continuously applies an upward force to the coiled tubing (as shown in Figure 2 below), which is the same as the betting operation principle, and can also lift the load (pipe light) in real time with the coiled tubing of the square injection head.

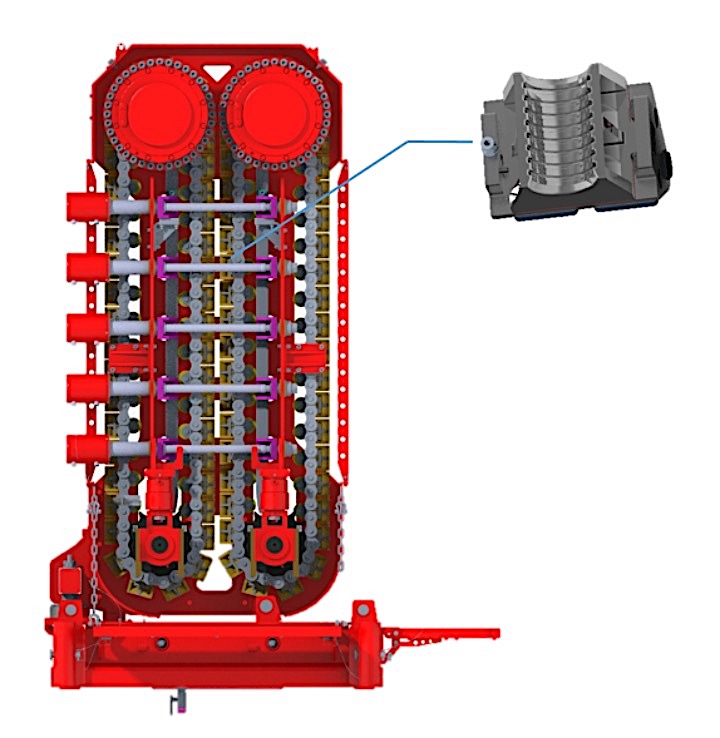

3 Working principle of the injection head clamping system

The injection head clamping system is the core area of the entire injection head, and the clamping system is functionally divided into two parts: clamping and transmission. In the process of operation, the on-site personnel adjust the clamping cylinder and tensioning cylinder in real time according to the experience and recommended load, clamping and tensioning curves.

The lifting and betting of the injection head on the coiled tubing are coordinated by the two parts of clamping and transmission, and the clamping cylinder pushes the clamping push plate and then transmits it to the slip to realize the clamping action of the coiled tubing. The transmission system drives the slip through the rotation of the roller chain to realize the continuous rise or fall of the coiled tubing.

Related testimonials

Sany Renewable Energy's first offshore engine "big on small" project was officially launched

2025.06.30

Sany Offshore full range of electric heavy fork press conference

2025.06.30

Xibei Power and Sany Renewable Energy have cooperated strategically to jointly promote the application of sodium battery energy storage

2025.06.29

0 comments