Increase production and efficiency! Sany electro-hydraulic control fully mechanized mining equipment has a great reputation!

2022.11.15

Shaanxi Xianhe Industrial Co., LtdLocated in Zichang City, Yan'an City, Shaanxi Province, with an annual coal output of 900,000 tons, the average thickness of the No. 3 coal seam is 650 mm, and the average thickness of the No. 5 coal seam is 850 mmExtremely thin coal seams。In order to overcome the harsh working conditions of extremely thin coal seams and improve the safety of mining work, in December 2020, Shaanxi Xianhe Industrial Co., Ltd. finally purchased it after many inspections and investigationsSany reinstalled two sets of electro-hydraulic fully mechanized mining equipment。In the past two years, the equipment has always been running stably and maintaining a very low failure rate, which provides a strong guarantee for the production and efficiency increase of Xianhe Industry. At the same time, the Sany electro-hydraulic control system detects the real-time status of the hydraulic support and realizes automatic control, which greatly reduces the labor intensity of the work and promotesIntelligent and less manpoweredExploitation.

At the beginning of 2022, based on the excellent performance of the first batch of equipment, Xianhe Industrial purchased two sets of Sany electro-hydraulic fully mechanized mining equipment again, which also achieved excellent results.Through the successful application of Xianhe Industry, Sany electro-hydraulic fully mechanized mining equipment has become famous in the surrounding areas.Yan'an Beineng Industrial Co., Ltd., Zichang County Fanzuiwan Coal Mine, Yanchuan County Xintai Coal Mine, Shaanxi Yongming Coal Mine Co., Ltd. and many other coal minesIt has successively chosen to use the complete set of Sany electro-hydraulic fully mechanized mining equipment.

Sany reloading electro-hydraulic control system is a complete set of equipment for safe, efficient and automatic control of hydraulic supports, a key technology and equipment to realize the automation and intelligence of fully mechanized coal mining, a key foundation for realizing a less manned working face and an unmanned working face, and one of the core components of the smart mining system.

# System features #

01

High real-time performance

The working face is integrated with a CAN bus link with the centralized control center along the groove, no relay equipment, the communication delay is ≤20ms, and the remote control of the bracket is real-time.

02

Compact and durable

The height is 120mm, the protection level is IP68, and the average trouble-free operation time of the system is more than 6000 hours.

03

Precise positioning

The controller integrates UWB module, with personnel,ShearersThe high-precision positioning function is accurate ≤0.2m.

04

Scalability

A variety of expansion interfaces such as Modbus, USB, and analog are reserved to meet the needs of advanced intelligence.

# System Architecture #Based on the ARM Cortex-M4 core microcontroller,It adopts non-master-slave bus and two-wire balanced transmission architecture

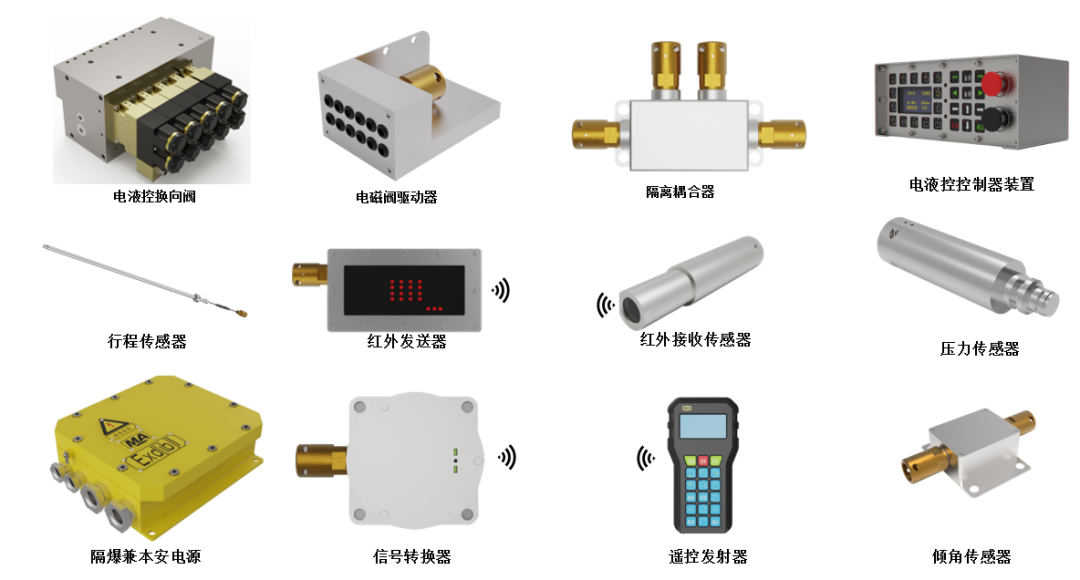

# System configuration #The hydraulic support electro-hydraulic control system is composed of a bracket controller, a solenoid valve driver, an electro-hydraulic control reversing valve, a DC regulated power supply, a power adapter, an isolation coupler, a signal converter, a remote control receiver, an infrared transmitter/receiver, and a variety of sensors such as pressure, stroke, inclination, and proximity.

Control the support, lifting, lowering, moving, pushing and other actions of the hydraulic support, and realize the adjacent/partition control, remote control/remote control, single/group automatic control, linkage control with the shearer, and the emergency stop function of the whole line.

# System functions #

01

Control functions

▪ Hydraulic support adjacent frame/partition motion control;

▪ Hydraulic support group motion control;

▪ Automatic pressure replenishment of hydraulic support column;

▪ Automatic control of the whole working face with the machine;

▪ Handheld terminal remote control.

02

Fault diagnosis and safety control function

▪ Solenoid valve fault diagnosis;

▪ Controller hardware fault diagnosis;

▪ Bus communication fault diagnosis;

▪ The human frame is locked, and the shearer is anti-collision.

03

Information monitoring function

▪ On-line monitoring of hydraulic support column and push;

▪ On-line monitoring of hydraulic support guards and telescopic beams;

▪ On-line monitoring of hydraulic support attitude;

▪ On-line monitoring of shearer location and personnel location.

Recommended products

MG330/730-WD

Shearer MG330/730-WDRelated testimonials

Sany Offshore full range of electric heavy fork press conference

2025.06.30

Good news! Sany Heavy Equipment won 2 "China Patent Awards"!

2025.06.25

The acceptance ceremony of Shanxi Shanxi Huifeng Xinxing Coal Industry Co., Ltd.'s intelligent fully mechanized mining machine was held in Sany Heavy Equipment Shenyang Industrial Park

2025.06.24

0 comments