The first layer of SPCS components of Shanghai Xinbang project was successfully hoisted!

2022.11.20

Trinity Construction

Recently, the hoisting of the first floor of the SPCS cavity wall of the 12# building of the 07-01 plot project in Xinbang Town, Shanghai was successfully completed, marking the official entry of the SPCS structural technology system of the project into the construction stage.

△ The first hoisting on site was completed

The project is located in Xinbang Town, Songjiang District, with a total construction area of 103,000 square meters and a seismic fortification intensity: 7 degrees (0.10g). The 2~12# building adopts the SPCS system, with a total of 11 monomers. Among them, there are 16 floors above ground for 2# and 3# floors, and 17 floors for 4#~12# floors, and the prefabricated components include SPCS cavity walls, prefabricated laminated panels, prefabricated staircases, prefabricated balcony panels, prefabricated air-conditioning panels and other components. The prefabrication rate of each monomer meets the requirement of 40% prefabrication rate.

With the strong support of the construction unit, the design unit and the general contractor, after careful planning in the early stage of the project, the SPCS components from the BIM intelligent deepening design to the fully automatic intelligent production of the PC factory, coupled with the technical guidance of the construction empowerment team, the on-site construction was very smooth, and the hoisting of the whole floor of the 12# building was completed in only 3 hours, which saved more than 40% of the time compared with the traditional PC component hoisting.

The intelligent deepening design adopts SPCS+P/R software, which realizes one-key splitting and one-key drawing on the basis of the traditional structural calculation model, which greatly improves the efficiency and accuracy of the deepening design and shortens the cycle of the deepening design. The data produced by the software can also directly drive the production of equipment in the factory, realizing a seamless transition from design to production.

Relying on the SPCP intelligent construction platform, it can also realize online collaboration, accurate delivery, and hoisting of components upon arrival, without the need to add additional yards and secondary reloading of components, which greatly improves the convenience of construction.

With the support of the on-site empowerment team, the workers adopted the standard "hoisting and fixed pouring test" construction method, and it only took 6~8 minutes to install a wallboard, which refreshed the fastest speed of local PC installation and won unanimous praise from the on-site personnel.

△ The effect of wall panel installation is completed

The application of SPCS cavity wall in this project has the following advantages:

01

Good structure and high quality

Cavity lap and post-pouring, the overall safety is high, the flatness is good, the components are produced by automatic turning equipment + high-precision mold table, the flatness of the outer surface is controlled within 2mm, and the plaster-free effect can be achieved on both sides, which can avoid the common quality problems such as hollow drum cracking caused by on-site plastering.

02

Good waterproofing

The cavity wall is equivalent to cast-in-place, and the exterior wall is more waterproof and free from the hidden danger of water seepage.

03

Fast installation and short construction period

The middle cavity has high fault tolerance and fast installation speed; The component does not have reinforcement on all sides, which avoids the collision problem with the dark column reinforcement caused by the reinforcement on three sides of the traditional component, and the on-site construction process arrangement is more flexible, and each layer can easily save 2 days of construction period.

04

Construction province

The weight of the components is light, and the weight of cavity components of the same size is reduced by 50% compared with the traditional PC wall, which can greatly reduce the cost of tower cranes. No sleeve grouting is required, reducing rebar, formwork and plastering labor.

05

Environmentally friendly

Low-carbon environmental protection, energy conservation and emission reduction, in line with the green industrial structure of less pollution, low loss and sustainable development; Actively respond to the national dual carbon policy.

The successful completion of the first floor hoisting is an important milestone node of the project, marking the successful application of the SPCS structural technology system in the project, and the whole process of the project has achieved phased results. The East China Construction Team will take this as a starting point to continue to do a good job in various empowerment work to help the project achieve the goal of "better, faster and more economical".

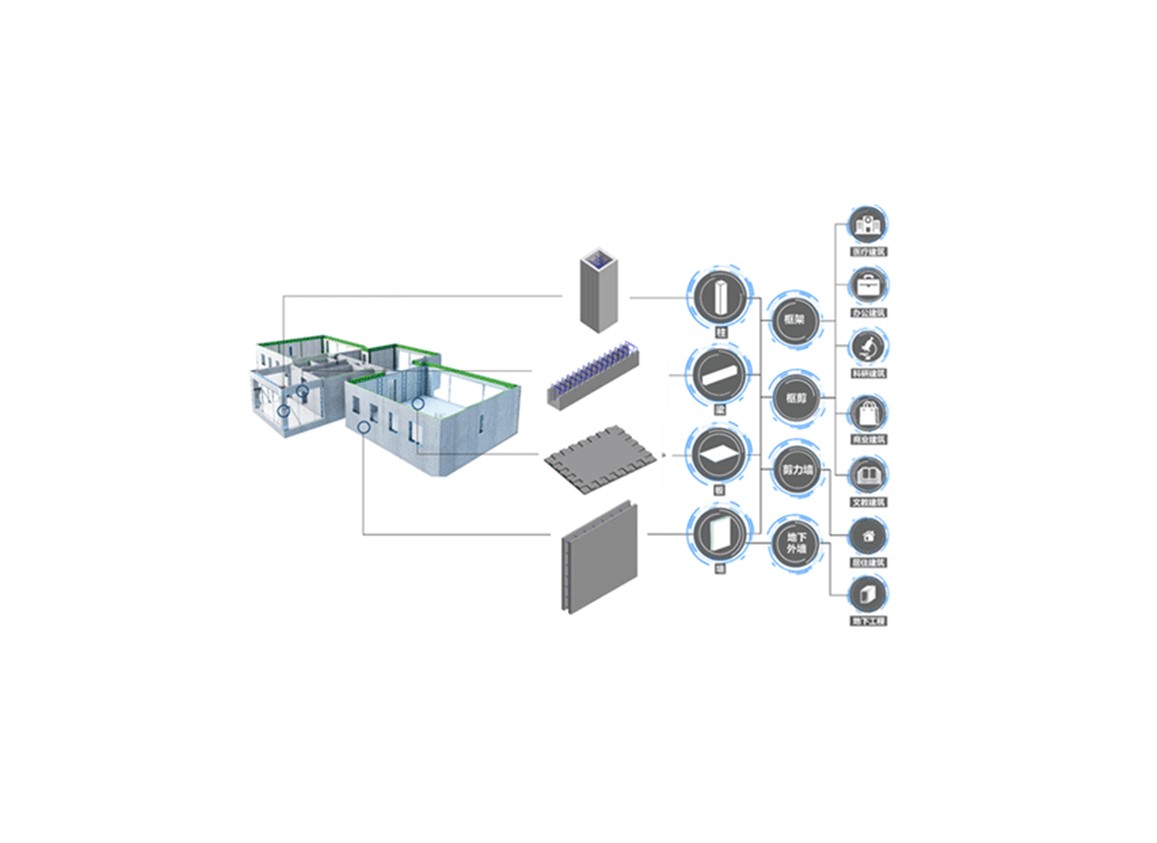

SPCS structural system

Structural standardsRecommended products

Related testimonials

Sany mobile crushing and recycling equipment is sent to Africa and shines all over the world!

2025.06.23

Changsha Housing and Construction Special Report - Sany Construction Engineering "Building and Enjoying Cloud Platform and PC Intelligent Production Line"

2025.06.20

Deepening strategic cooperation and jointly expanding the Southeast Asian market -- Sany Group successfully signed a strategic cooperation agreement with well-known enterprises in Southeast Asia

2025.06.20

0 comments