Based on demand, continue to improve | Sany intelligent roadheader welcomes new development

2023.02.27

In the context of the fourth industrial revolution and the third energy revolution, the state has put forward higher standards for the intelligent construction of coal mines, and customers have also put forward higher requirements for intelligent tunneling production. Sany Heavy Equipment Intelligent Roadheader responds to the call of the country, conforms to customer needs, and continues to improveIntelligent TBMsProduct competitiveness, speak with technical strength, win the trust of customers, and provide a steady stream of power for the intelligent construction of mines.

Efficient and reliable - hard power

A full range of products to meet the needs:Sany intelligent roadheader covers the whole spectrum and meets the intelligent needs of various types of roadheaders. Intelligent tunneling can be realized under all working conditions such as all-coal roadway, semi-coal rock roadway, and all-rock roadway to meet the equipment needs of customers for various actual excavation conditions. According to the different operating habits of customers, the roadheader can be remotely operated in multiple locations such as the proximal working face, the remote underground chamber, and the ground dispatching platform, so as to solve the problem of fixed operation position and free the operator from the harsh excavation environment. According to the configuration needs of different customers, the underground remote control can be equipped with an underground centralized control room or a simple operation platform, and the underground remote control can be equipped with a simple operation box, a ground centralized control center, and a ground customized dispatching platform, breaking the restrictions of mine conditions and meeting customer production needs.

Intelligent technology promotes the application:Sany Intelligent Roadheader pays attention to customer pain points and conducts research on the use, safety, and maintenance of equipment.The inertial navigation system is used to realize the real-time attitude detection of the roadheader, and the continuous working time is >2h, the error of heading, rolling angle and pitch angle is <0.1°, and the deviation error is <8cm/10m. LiDAR is used to detect and locate the static position of the roadheader, and the positioning error is <3cm; The dynamic position of the roadheader is detected by multi-sensor fusion technologies such as magnetoevogen displacement sensor, walking odometer and positioning sensor in the cylinder, with a detection error of < 0.1° and a cumulative footage error of < 20cm/10m.

In order to meet the needs of different customers for the use of intelligent roadheaders, Sany intelligent roadheader has built an automatic cutting process model library, covering the automatic cutting process of all coal, semi-coal and all rock roadways, with a total of 27 types of automatic cutting process, covering more than 80% of the actual working conditions. Through the friendly human-computer interaction interface, simple operation mode, adaptive adjustment of cutting speed, fast tunneling operation, inertial navigation alignment and alignment time <15s. The roadway is accurately formed through telescopic compensation technology, position independent deviation correction, walking automatic straightening, path independent planning, and boundary forming algorithm, and the forming error is < 10cm.

In order to ensure the safety of the tunneling operation, Sany Intelligent Roadheader has developed an intelligent personnel safety protection system. Through high-precision positioning, boundary limit and other technologies, the active + passive form of protection system is realized, and high-precision positioning personnel are prevented from entering by mistake. Through the thermal imaging camera and intelligent AI gimbal camera, intelligent AI accurate identification and protection are realized to prevent personnel from entering dangerous areas.

Through the predictive maintenance system of roadheader motors, the operation status of roadheader oil pump motors and cutting motors can be understood in real time, the operation data can be analyzed online, and the health degree can be predicted, maintenance opinions are provided, and data decision support is provided for the early repair and replacement of critical parts.

Smart Brain - Soft Power

Intelligent Remote Control Operating System:Sany intelligent roadheader not only has reliable intelligent equipment, but also has a friendly human-computer interaction system. The "TBM Remote Intelligent Operating System" can freely set the automatic cutting parameters by the customer, so that the automatic cutting can meet the individual needs of different customers. Through the software system, the current working status and historical operation information of the roadheader can be viewed, and the customer's grasp of the working status and work process of the equipment can be enhanced.

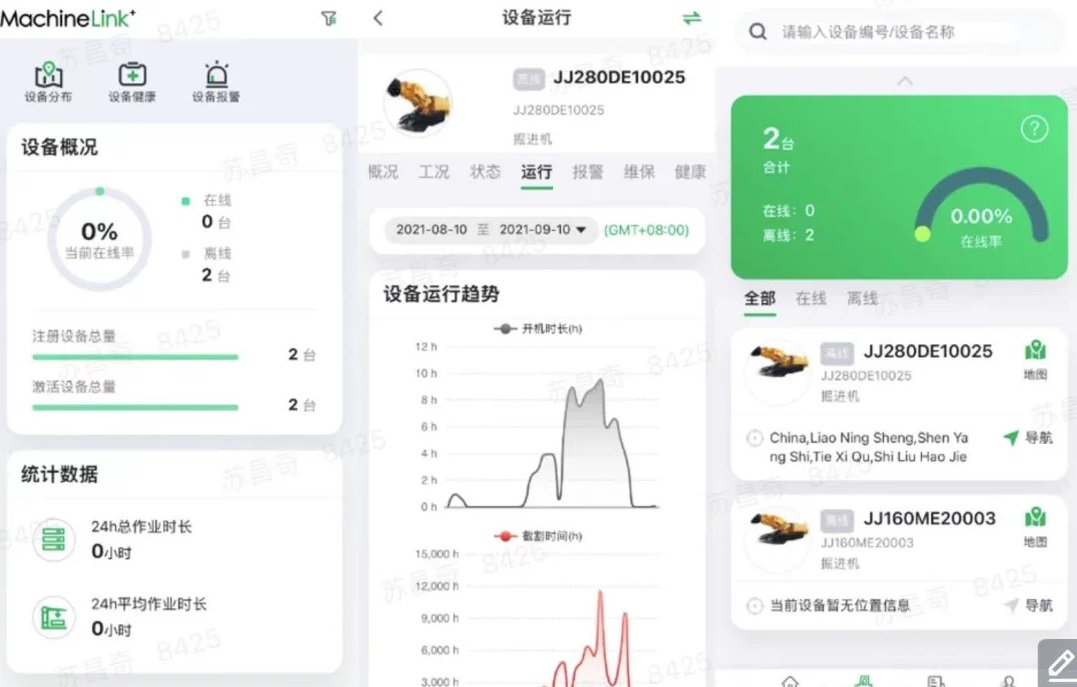

Intelligent terminal data management on the cloud:In order to facilitate operators and management personnel to flexibly control and view the working status of the roadheader in real time, the Sany intelligent roadheader is also equipped with an intelligent mobile control terminal IMC and a data cloud management system. The operator can control the TBM at the proximal end via the intelligent mobile control terminal IMC, providing the operator with a completely new operating mode. The working data of the roadheader is uploaded to the cloud in real time, and the management personnel can view the operation data of the roadheader through the smart cloud butler app of the mobile phone, so as to realize the cloud management of the roadheader data.

Digital Twin Platform for Intelligent Tunnelling Operations:For the intelligent construction of the excavation face, Sany Heavy Equipment has developed a digital twin platform for intelligent tunneling operations with the intelligent roadheader as the main body, forming two major scenarios of coal mine scene and excavation face scene, and four monitoring systems, including roadheader system, belt system, power supply system and safety monitoring system, which empowers the intelligent construction of the entire comprehensive excavation face and provides a complete solution for the intelligent construction of the customer's excavation face.

With the blessing of strong "hard power" and "soft power", Sany intelligent roadheader has won a number of industry awards and has been widely recognized by customers. At present, the market share of Sany intelligent roadheader exceeds 80%, leading the industry, and more than 300 mines have enjoyed the benefits brought by Sany intelligent roadheader. In Shanxi, Guizhou, Xinjiang, Henan, Heilongjiang and other places, intelligent demonstration "model mines" have been built successively, among which, Guizhou Nuodong Mine, Shanxi Chengzhuang Mine, Guizhou Shanjiaoshu Mine, Xinjiang Yushuling Mine automation utilization rate has reached more than 80%. The breakthrough of "Double 80" is a milestone for the development of Sany Heavy Equipment Intelligent Roadheader, marking that Sany Intelligent Roadheader has made outstanding contributions to the intelligent construction of coal mines.

Based on customer needs, continuous product improvement! Sany Heavy Equipment Intelligent Roadheader will continue to upgrade its technology, continuously improve its product competitiveness, improve its customer experience with high-quality products, and lead the intelligent construction of the mine to move forward!

0 comments