The most comprehensive practical experience in history takes you into the Sany micro hybrid pump truck!

2023.03.09

Sany pumping

Under the general trend of energy saving, emission reduction and efficient production, more and more new energy engineering equipment has been put into the market, and the product we want to show you today is Sany 620S micro-hybridPump trucks。

As the world's first mass-commercial "low-carbon intelligent micro-hybrid electric pump truck", Sany 620S micro-hybrid pump truck inherits the latest technical advantages of the S series, and has three major functions: electric standby, electric washing, and electric air conditioning. According to the actual situation, the micro hybrid pump truck can save you 4-50,000 yuan in operating costs every year.

You must keep the next Sany 620S micro hybrid pump truck operation experience guide!

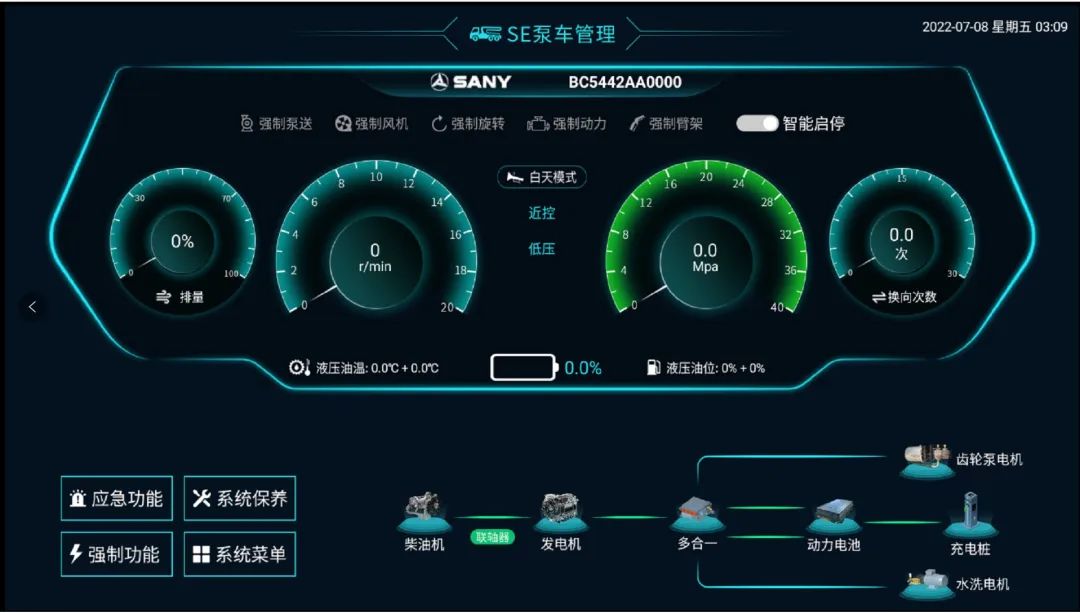

Compared with the fuel pump truck, the battery box is added to the middle section of the right side of the micro hybrid pump truck, the electric water pump and stirring motor are added to the middle section of the left side, the electric air conditioner is added to the back of the cockpit, and the engine is added to the shaft generator. All the additional hardware of the micro hybrid pump truck can be viewed on the home page of the large screen in the central control of the cab.

Intelligent self-charging

During driving and pumping, the SYAS controller can monitor the operating conditions of the SANYI engine and the battery level in real time. In order to maintain the maximum efficiency of power generation, the pump truck automatically runs the self-charging mode only in the most fuel-efficient section of the engine, and the charging marker is displayed intermittently on the large control screen.

Electric standby

When the pump truck is waiting for material, the waiting mode can be switched automatically or manually, and the energy consumption of electric waiting is 4 kWh per hour.Automatic switching of waiting mode:The pump truck will automatically switch between the waiting mode by default, and the corresponding switch (automatic start and stop) can be found on the large central control screen. When the pump truck has 5 minutes of fuel standby, the engine will automatically stop and switch to the electric standby mode until the "engine start-stop" button of the remote control is operated. If the average waiting time of your pump truck is more than 10 minutes, it is recommended to turn on the automatic start-stop function in the large central control screen.

Manual switching of standby mode:The operator can switch the waiting mode by himself through the "engine start and stop" button on the remote control;The Sanyi Yitz engine adopts no-load start technology with gear to protect each remote start and stop of the engine;According to the big data statistics of pump trucks, the waiting time of a single pump truck accounts for about 50% of the operation time, and the energy consumption of waiting materials accounts for about 25%. According to the calculation of 55,000 cubic meters a year, the fuel consumption of waiting materials can save 30,000 yuan.

Electric air conditioning

When the engine is not started, the electric air conditioner provides the operator with a long and comfortable rest. The energy consumption is only 0.8 kilowatt-hours of electricity per hour, and the fuel consumption of air conditioning can be saved by 10,000 yuan based on the annual use time of 560 hours.

Electric washing

Compared with the high-energy washing of fuel pump trucks, electric washing only needs 2 kWh of electricity for half an hour, which can be turned on anytime and anywhere, which is quieter and more energy-saving. Based on the calculation of 140 hours of use in a year, the fuel consumption of car washing can save 12,400 yuan.

The rational use of the micro-hybrid pump truck can also reduce most of the engine idle time and reduce engine loss. The cost of engine maintenance and urea consumption due to idle speed can be reduced by about 7,000 yuan.

According to the actual situation, the micro hybrid pump truck can save you 4-50,000 yuan per year.

0 comments