Go up the mountain and down to the sea to see how SY600EP can be exquisite

2023.08.31

Sany Heavy Machinery

The mountain is not high, and there is a fairy name

The water is not deep, and if there is a dragon, it will be spiritual

The working conditions are changeable, and he can do it

Wharf mines, who compete with each other

SY600EP create a new multi-faceted money-making artifact for you

Environmental protection and energy saving, safe and reliable

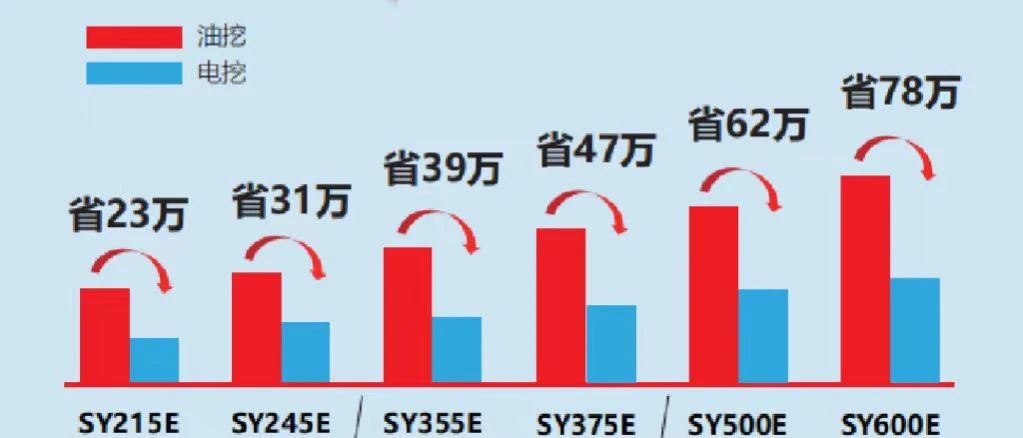

SY600EP is a 60T tractor excavator product built by Sany Heavy Machinery. The drag electric drive power system is used to realize the whole machineZero emission, low noise, to meet the needs of green construction;Compared with traditional fuel, it saves more than 50% of the use cost; Touch-screen 11-inch color display with SanyExclusive Evision APPIt is convenient for customers to use and manage.

High securityThe first in the industry to be equipped with a standard leakage protection system to achieve remote power failure and high-level lightning protection design to ensure the safety of the driver's operation;

High reliability20000H reliability test of core components; The vehicle has completed 31 performance tests, and the vehicle has 3000 hours of reliability mining test;

High quality5-year or 10,000-hour warranty for three electric vehicles, stepless speed regulation, energy saving of 15% under all working conditions;

New noise reduction: For mining conditions, FOPS/ROPS cab and new dustproof and noise reduction technology are developed, which is 5 times safer than ordinary cabs, and the cab noise is reduced by 5dB, which is far better than other brands.

Permanent magnet synchronization: Using high-power permanent magnet synchronous motor, intelligent temperature control water cooling and heat dissipation (with backflush function), so that the motor and electronic control work at the best temperature at all times, and prolong the service life of the motor electronic control.

Compared with the single-speed asynchronous motor solution, the energy efficiency is increased by 10%~20%. Compared with traditional quay cranes, the efficiency is increased by 2.5 times. Compared with traditional excavators, the gear power speed is set the same, and the motor response speed is 10 times faster than that of the fuel engine. Compared with the market modification machine, the efficiency of all working conditions is 15% higher than that of asynchronous motor.

The wharf mine is richly configured

The positive flow hydraulic system that has been verified by severe mining conditions realizes the intelligent distribution of flow and power to adapt to different working conditions. It can also be selected according to different working conditionsLifting cab, extended arm, differentAttachmentswait。

SY600EP Dock Version: Standard Lifting Cab,One-button operation cab elevation 2.6m,It is convenient to clean the cabin during wharf operation, lengthen the platform and increase the counterweight, and improve the stability of the whole machine in wharf operation.

AgainstUnder different working conditions, one mine and one bucket are adopted, and the bucket configuration is diversified:Investigate the field conditions and customer needs, form a map of large-scale mines, formulate a "one mine, one bucket" strategy, improve construction efficiency, enhance product value and customer profitability.

Save money and worry, reliable and stable

save money: Electrically driven, greatly reducing the cost of daily use, away from the trouble of refueling.

save worry: Three-electric maintenance-free,5 years or 10,000 hours of the industry's longest warranty; No anxiety about battery life, 24-hour worry-free work; The maintenance is less than half, and there is no need for maintenance for oil filter, machine filter, diesel filter, air filter, engine oil, etc.

High reliabilityThe boom and stick box structure are strengthened design, high-strength steel and life-extending welding process, the key supports are integrated with forgings and castings, the overall structural parts are optimized by multi-body dynamics and fatigue simulation, and advanced detection technologies such as multi-condition stress test, durability test, two-axis fatigue test and full flaw detection are used to comprehensively improve the reliability of key structural parts.

More stableReinforced lower frame, heavy-duty rollers and carrier wheels, super wear-resistant tracks, and reinforced drive wheels and idlers, and the car body is equipped with full protective track guards to ensure the strength of the running gear in harsh environments, and also allow customers to have a long service life.

Energy saving and environmental protection, all-round expert

Noise reduction, energy saving, safe and reliable

SY600EP, enjoy the ultimate experience

0 comments