"Dig" to strength! Sany "unmanned" intelligent excavator delivered smart mines in batches!

2024.06.17

Trinity Heavy Machinery

The 14th Five-Year Plan proposes to accelerate the pace of digital transformation of mines, and smart mines have ushered in new development opportunities. In this context, Xinjiang's intelligent mine planning has been comprehensively promoted and implemented.

In the face of the inevitable trend of digital transformation of national mines and the wave of the "5G" and "AI" era, Sany has achieved fruitful results in the process of smart mines.In June, Sany Heavy Machinery successfully delivered SY1350H remote control excavator in batches in a mine in Xinjiang, contributing to the construction of smart mines in Xinjiang.

Xinjiang's mine intelligence plan proposes that by 2025, all coal mines produced in Xinjiang will reach the primary intelligence level and above, and the coal mines that are suitable for construction conditions will reach the middle and advanced intelligent level.

Smart mines include decision-making management, production execution, control, and equipment, and remote control excavators are the most important part of the equipment layer.Sany remote control system, after years of technical precipitation and market verification, is safer, more reliable and more intelligent.

Sany remote control system to create an intelligent benchmark in the industry

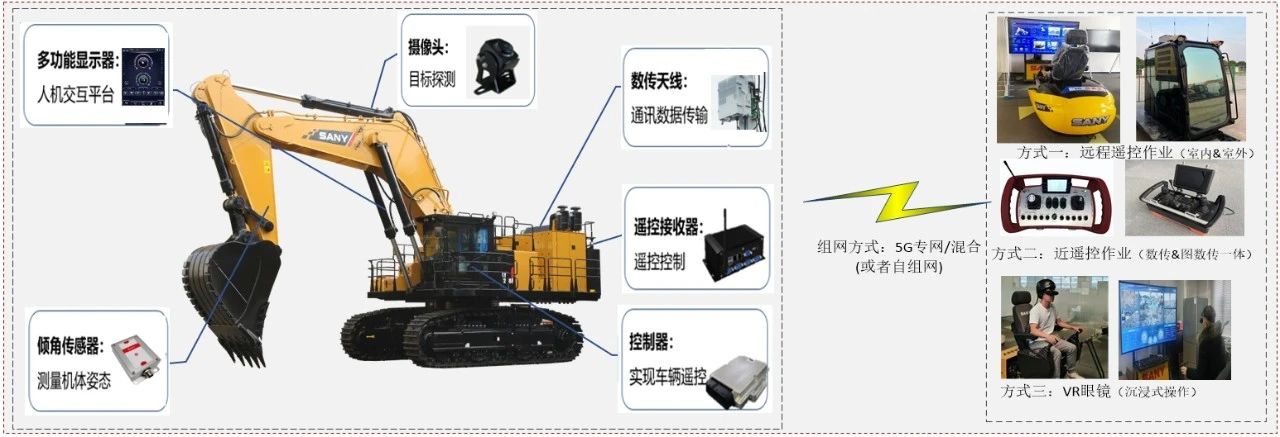

Sany remote control system is mainly composed of remote control excavator system, communication system, remote control operating system, can provide customized remote control solutions for special scenarios, covering Sany 1.6T~400T full model front or rear installation, in this Xinjiang SY1350H remote control excavator, equipped with many Sany remote control black technology.

Sany remote control excavator system supports different operation modes such as native machine, 1:1 mobile remote control cockpit, long battery life, and portable handheld remote control to meet the needs of customers in different scenarios.

At the same time, the system adapts to fast networking, supports 5G communication technology/WIFI networking fast switching, millisecond-level ultra-low signal delay, control signals, and 360° picture lossless and fast transmission.

The Sany remote control system is also equipped with multiple safety protection functions, including signal heartbeat detection, on-site remote control emergency stop, remote remote control emergency stop and vehicle perception and control measures to ensure the safety of construction operations, all-weather remote wake-up function, and support all-weather remote control excavator one-click power on/down, start-up, shutdown and other functions, which is convenient and practical.

In the construction of smart mines, the Sany remote control system also provides many intelligent auxiliary functions through special equipment and technical optimization.

Bucket tooth recognition system:Through the application of image recognition algorithm and dynamic tracking algorithm, the status of the bucket teeth is monitored and the early warning information is fed back in time, and the recognition detection rate is higher than 95%, improving the accuracy and safety of operation.

Intelligent weighing system:Through automatic weighing and data calculation, real-time monitoring and push of the loading weight of a single bucket or the whole vehicle can be realized, improving loading efficiency and measurement accuracy.

Intelligent and precise positioning function:By installing a 2D guidance system, it provides real-time height and slope guidance for the operator; The 3D guidance system realizes the combination of digital construction and design base drawing, and guides the operator to complete high-precision work efficiently and with high quality.

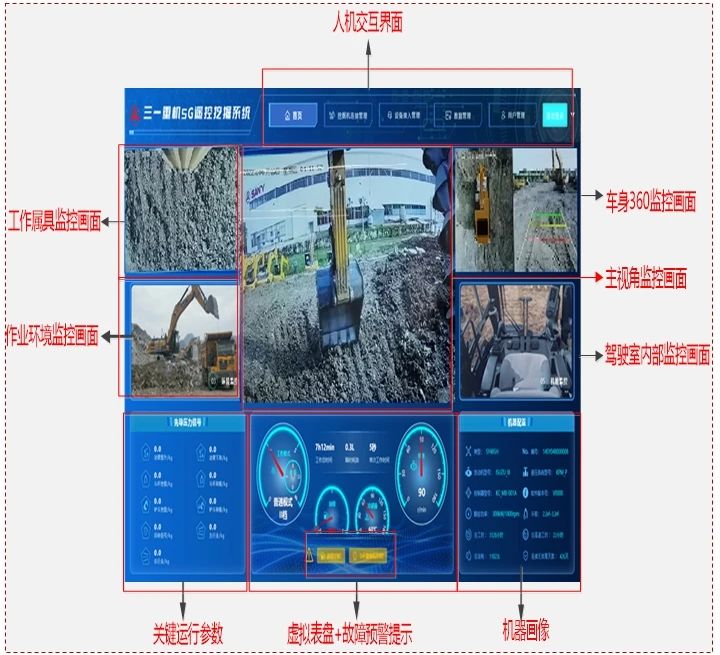

Remote control smart large screen:Real-time display of excavator's energy consumption information, operation information, fault codes and energy efficiency reports, which provides important data support for decision-making management and production execution.

Trajectory playback function:By transmitting the excavator location information back to the scheduling system, the excavator trajectory information can be viewed in real time through the remote control smart screen.

Fault diagnosis and fault prediction functions:The fault diagnosis information on the excavator side display screen is synchronously projected to the remote control terminal operation screen, and the potential fault development trend is effectively predicted and reminded of the development trend of potential faults.

These black technologies not only improve operational efficiency and accuracy, but also enhance the safety and sustainable development of mines. There will also be more technical black technologies such as remote voice interaction, personnel authentication and behavior recognition, blind spot detection, driver fatigue driving detection, digital model and excavator synchronous collaboration, so stay tuned.

Sany Heavy Machinery has always been committed to providing customers with high-quality products and services, and has always adhered to independent innovation. In the future, we will continue to promote the development of smart mines, improve the management and decision-making capabilities and production execution efficiency of mines, and expand the construction of smart mines nationwide.

In the future, Sany will continue to develop technology and market expansion in mine intelligence, strengthen the integration with new technologies such as "5G" and "AI", help the mining industry achieve digital and unmanned transformation, and provide more advanced intelligent assistance solutions for mines.

0 comments