Efficient, smart, zero-carbon! Sany smart filling technology fully promotes the construction of green mines

2024.07.08

The mining industry's desire to achieve zero emissions without damaging the ecological environment means adopting a sophisticated approach to mining that avoids extensive destruction of vegetation cover and surface structure. Waste cannot be discharged directly into the environment; timely filling of goafs; And fully recycle and reuse ore resources.

A complete set of professional and reliable backfill mining technology and equipment is the strongest "weapon" to achieve a complete green mining process! As the leader of the world's construction machinery industry and a practitioner of green mine construction, Sany Heavy Industry has launched a full range of equipment for mine filling operations by virtue of the world's leading R&D innovation level and advanced manufacturing technology, becoming the only complete set of filling equipment provider with independent research and development, independent production and independent intellectual property rights in China, bringing super help to the harmless disposal and resource utilization of bulk solid waste such as coal gangue!

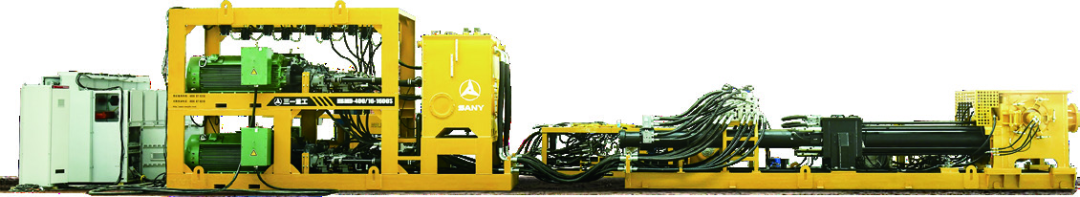

Sany filling equipment is tailored by the industry's largest R&D team, and the crushing system, mixing system, filling system and intelligent control system work together to operate efficiently, and can provide customers with all-round and high-level solutions.

The six technical advantages of "filling pump", the main force of the filling system, are more efficient

1、Large-displacement pumping technology

Efficient pumping, saving time and effort. The larger displacement filling pump can hold more material and convey material quickly and continuously, which is conducive to speeding up the project schedule while saving time and labor costs. At present, the new filling pump has a displacement of up to 400m³/h, a pumping pressure of up to 20MPa, a power of up to 1800kW, and a maximum conveying distance of more than 8 kilometers.

2、PCF multi-power constant current technology

No fear of pipe blockage, high reliability; The hydraulic system adopts PCF constant flow system to eliminate pressure peaks and greatly improve reliability; Large-flow cartridge integrated valve manifold, flow rate up to 6000L/min, reliable structure, small pressure loss. Multiple sets of power can work independently or in combination, without fear of power failure leading to pipe blockage.

3、Ultra-abrasion resistant technology

High-tech materials to ensure product performance; The use of Sino-German high-tech materials and advanced technology not only improves the product performance, but also reduces the wear and tear between parts, prolongs the service life of the equipment, and is more safe and durable.

4、Differential pressure sensing reversing buffering technology

Optimize the reversing process and improve safety; The differential pressure induction reversing technology and the main cylinder electric proportional control buffer technology are adopted to effectively shorten the reversing time and improve the pumping efficiency. Eliminating pressure spikes when the hydraulic system is reversed also further increases equipment and construction safety.

5、Automatic double-retract piston technology

One-button operation, convenient and fast; The classic limit cylinder design, one-key operation realizes the double withdrawal of the concrete piston to the water tank. 2 pistons can be replaced within 1 hour, which is more convenient and faster.

6、Circulating filling line technology

Realize self-dredging of pipelines with strong flexibility; Sustainable filling. It has multi-functional valve systems such as diverter valves, globe valves, cleaning valves, etc., and local pipeline blockage, which can switch flow channels to achieve the purpose of pipeline self-dredging.

Mixing system "filling special mixing plant": full mixing, more intelligent

1、Dedicated mixer

Stir well and have low residue; The mixing plant system for filling is a special mixing plant developed by Sany for the filling business, the main engine adopts a double-horizontal shaft forced mixing host, which boils in a network during mixing, and the finished material is stirred more fully and evenly, with low residue and no stuffiness, so as to eliminate the risk of filling and plugging.

2、Dedicated sealing system

Safe and reliable; The mixer has developed a special sealing system, which can automatically compensate, and effectively control the temperature, humidity and impurities of the mixing environment to ensure the quality of the finished material; and the reduction of dust and gases generated during agitation to protect the health of operators.

3、A new generation of intelligent mixing control system

Precise and efficient; The dual-main machine metering system and rotary dispensing system can improve the mixing efficiency and reduce energy consumption. The intelligent material level technology of the powder tank can detect in real time, accurately measure, and batch. Predictive maintenance technology realizes fault prediction and intelligent maintenance reminders. There is also a centralized remote control system and intelligent management system to grasp the project and park situation in real time to ensure the safety of the park.

Crushing system full range of crushers: precise matching, more professional

TrinityJaw crusher

Simple structure and easy to operate; It is widely used in various hard rock coarse crushing operations, the crushing horizontal stroke is increased by 20%, the crushing efficiency is faster, and the output is increased by 5%; The integrated design is easy to install and evenly loaded, and the hydraulic adjustment device can be intelligently adjusted, saving time and effort.

Sany cone crusher

Intelligent feeding, stable and reliable; It is suitable for medium crushing and fine crushing, automatic adjustment of discharge port, automatic pressure relief of overload accumulator, one-key cavity cleaning after material blocking, and intelligent monitoring of positive pressure and dust prevention to ensure the safe and efficient crushing operation. High-performance parts and customized cavity designs are designed for reliable wear resistance and long life.

Sany impact crusher

Large output and long life; It can be used for medium crushing and fine crushing, and the three-cavity involute cavity type is equipped with the third-cavity shaping impact plate, with a 50% larger volume, better discharge particle size, and a 20% increase in production capacity; Special impact-resistant and wear-resistant materials, the life of the hammer and lining plate can reach more than 1800h.

Sany vertical shaft impact crusher

Efficient discharge, easy maintenance; It is mostly used for shaping or sand making operations, with adjustable feed port and high-speed rotor line, which has a large throughput and higher crushing efficiency, and a one-time sand formation rate of >33%; Equipped with well-known brand wear-resistant parts and motors, using hydraulic power assist structure, less wearing parts, reasonable structure, effectively reduce operation and maintenance costs.

Sany double-chamber high-fine crusher

Dual system crushing, strong practicability; There are two sets of systems in the machine cavity, the upper and lower two-stage up-and-down double-blow grinding, and the middle crushing and fine crushing machine are completed by one machine, which can produce finished materials with good grain shape and excellent quality. It can be adjusted to the optimal particle size, and the discharge particle size < 15mm.

Intelligent control system: scientific management of the park, more intelligent

Relying on intelligent algorithms, intelligent sensing, comprehensive data analysis and other means, Sany smart filling technology scientifically analyzes and deals with the problems encountered in the whole process from raw material entry, crushing and screening, mixing and filling, and realizes the intelligent management of the filling park.

Driven by technological innovation and environmental protection concepts, Sany Smart Filling Technology not only improves the efficiency and safety of the mine filling process, but also sets a new benchmark for the sustainable development of the global mining industry. In the future, Sany will continue to uphold the concept of "all for customers, all from innovation", and continue to help the construction of green mines and smart mines.

0 comments