Sany Asphalt Station settled on Shengsi Island, leading a new chapter in the green construction of island infrastructure!

2024.08.21

Shengsi Island is located at the northern end of the East China Sea, is the center point of China's 18,000 kilometers of coastline, is the east gate and natural barrier of Shanghai, Hangzhou and Ningbo, has always been a military fortress, and is the only way for international sea vessels to enter and exit the Yangtze River Estuary, and has close ties with various regions of the Yangtze River Delta.

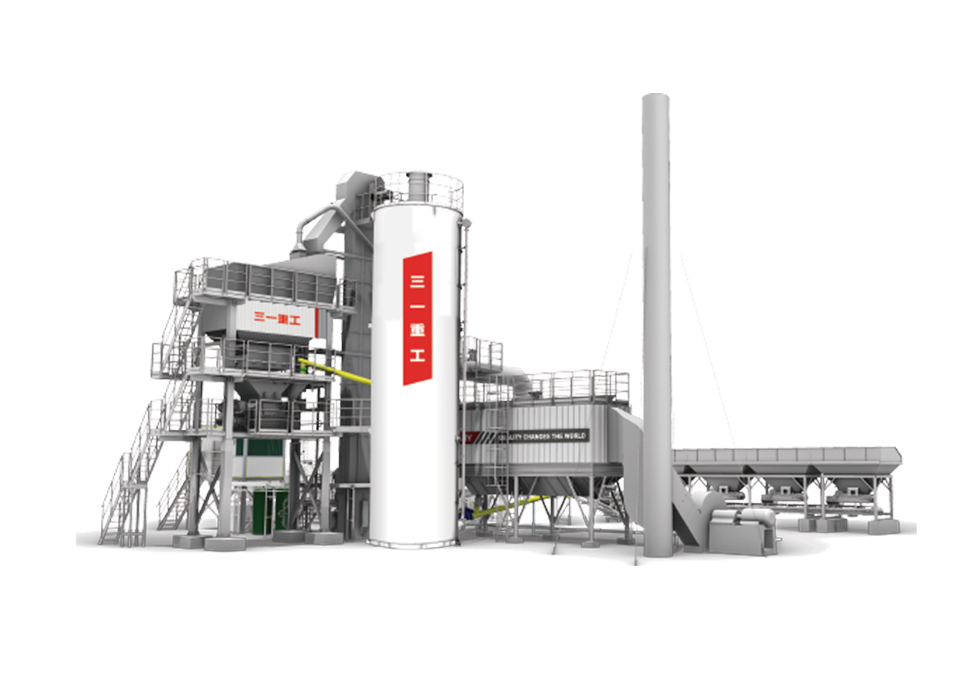

This shining pearl embedded in the coast of the East China Sea has recently ushered in an important milestone in infrastructure construction - Sany's new generation of SLB2000Pro environmental protection asphalt station was officially completed and put into use, and the construction of Shengsi Island and surrounding island roads will enter a new stage, and Sany asphalt station has set a new benchmark for the green development of the island area with its excellent characteristics of environmental protection, high efficiency and energy saving.

Environmental protection first, protect the blue sea and blue sky

Today, when environmental protection has increasingly become the consensus of the whole society, Sany SLB2000Pro asphalt plant is fully integrated into the green concept from design to production.

The advanced smoke and dust purification system and waste gas treatment device are used to ensure that the dust and harmful gases generated in the production process are effectively controlled, and the main building of the asphalt station is fully enclosed for production, and the four-fold negative pressure dust is suction to ensure that there is no dust leakage in the production process.

The asphalt flue gas at the finished product discharge place is directly burned by the environmental protection burner through the dust collection hood and flue gas pipeline, which can be 100% pyrolysis and oxidation, without secondary pollution, which protects the ecological environment of the surrounding sea and makes the sky bluer and the water clearer on Shengsi Island.

Efficient operation to accelerate the pace of island development

In the face of the complex and changeable environment and challenges of island construction, the SLB2000Pro asphalt plant has shown strong production capacity and flexibility.

The maximum production capacity of SLB2000Pro asphalt plant can reach 180t/h, the production efficiency is industry-leading, and the mixing cycle is shortened by 3-5S compared with the industry average level, and the mixing efficiency is steadily improved.

Breaking through the barriers in the industry, the first precise metering, aggregate pulsation measurement, asphalt secondary metering technology, dynamic data acquisition, closed-loop control, and the precision control error of oil-stone ratio is ≤0.1%.

Energy saving and consumption reduction, practicing the concept of sustainable development

In terms of energy saving and consumption reduction, the SLB2000Pro asphalt station also performs well. Sany independently developed energy-saving and environmentally friendly burners, the oil pump and fan are controlled by frequency conversion, and the three parameters of temperature, air distribution and negative pressure are controlled in a closed-loop manner, which is accurately adjusted, and the fuel consumption is reduced to 5.5 kg/t.

SLB2000Pro specially built C8 spray gun for domestic oil products, with atomization effect, good oil adaptation (all kinds of light and heavy oil, blended oil, heavy residue oil), strong ignition ability, and a fire success rate of >98%.

Automatic aggregate temperature control: Adaptive adjustment of flame opening, replacing manual operation, ensuring the stability of discharging temperature and saving energy.

Negative pressure automatic control: adaptive adjustment of the opening of the induced draft fan, replacing manual operation, avoiding insufficient negative pressure and ash in the drum; Avoid the problem of too much negative pressure and large particle size stones entering the dust collector, resulting in waste.

In addition, SLB2000Pro is also equipped with automatic diagnosis of key component design; Design remote data monitoring and analysis functions; The expert management system is set up with the function of automatic report analysis, which realizes the refined management of the production process, further reduces energy waste, and fulfills the corporate responsibility of sustainable development.

With the successful application of Sany SLB2000Pro environmental protection asphalt station in Shengsi Island, it has not only injected strong impetus into the highway construction in the island area, but also explored a new path for the green development of island infrastructure construction with its excellent performance of environmental protection, high efficiency and energy saving.

In the future, Sany will continue to uphold the mission of "quality changes the world", contribute green and intelligent solutions to infrastructure construction in more regions, and jointly draw a grand blueprint for a beautiful China.

0 comments