Provincial benchmark! Trinity was selected

2024.08.22

Sany Group

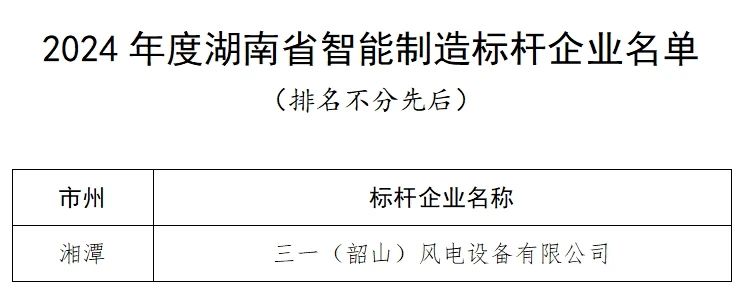

Recently, the Hunan Provincial Department of Industry and Information Technology released the list of intelligent manufacturing benchmarking enterprises and benchmarking workshops in Hunan Province in 2024.Wind power equipmentThe company was listed on the "2024 Hunan Province Intelligent Manufacturing Benchmarking Enterprise List".

Intelligent manufacturing benchmarking enterprises and benchmarking workshops are important indicators to measure the intelligent level of regional manufacturing industry. The relevant person in charge of the Provincial Department of Industry and Information Technology pointed out that the identification of intelligent manufacturing benchmarking enterprises and workshops aims to promote the whole industry to achieve the goal of "transforming one, driving a batch, and radiating one" by establishing industry benchmarks, and accelerate the intelligent transformation and upgrading of the province's manufacturing industry.

Sany Renewable Energy Shaoshan Blade Factory has the largest single wind turbine blade production workshop in Asia, with a production flow length of nearly 600 meters, which can accommodate 12 sets of molds for simultaneous production, and can produce 3,000 wind turbine blades per year. In 2023, the 104-meter onshore wind turbine blade rolled off the assembly line at Sany Renewable Energy's Shaoshan Blade Factory, setting a new record for the world's longest onshore wind turbine blade at that time.

Based on the "digital element platform" control system independently developed by Sany Renewable Energy, Sany Renewable Energy's Shaoshan Blade Factory combines innovative technologies such as digital twins, machine learning, and industrial vision to realize the intelligent supervision of all production factors of "people (workers), machines (equipment), materials (raw materials), methods (processes), and environment (environmental protection)", which greatly improves the management efficiency and operational accuracy of the factory.

By replacing manual work with large-area machinery and equipment, as well as automatic material distribution and finished product transfer, it is estimated that the production efficiency of Shaoshan blade factory has increased by 20% compared with traditional factories, and the average construction period of a single 100-meter-level blade has been shortened from more than 40 hours to about 30 hours, which greatly meets the supply needs of customers.

In the future, Sany will continue to play a benchmarking and exemplary role, accelerate the development of new quality productivity, and contribute to promoting the high-quality development of the manufacturing industry and realizing the beautiful blueprint of "three highs and four new".

0 comments