Heavy! Sany Construction launched a data-driven visual quality inspection system

2025.02.24

Trinity Construction

In the process of exploring the modernization of China's construction industry, prefabricated building technology has undoubtedly become a key force to promote the transformation of the industry. Among them, as the core component of prefabricated concrete components (PC components), the innovation and upgrading of production technology are particularly important.Trinity ConstructionIt is committed to providing "technology, equipment and cloud platform" for intelligent construction, among which, PC intelligent equipment, as a link in the production of intelligent construction, has a market share of more than 50% in the domestic public market for many years, and the level of digitalization and intelligence is leading in the world.Sany Construction Engineering will launch a series of articles on PC intelligent equipment, and this issue introduces the "data-driven visual quality inspection system".

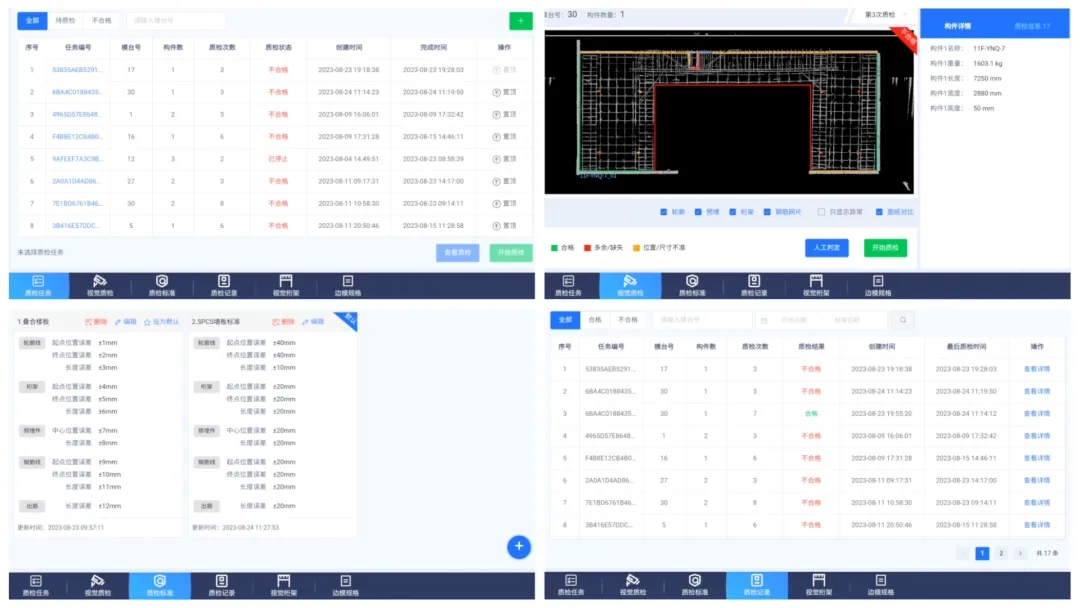

Sany vision quality inspection system is the core subsystem of SPCI-PMES in the central control room of PC factory, which is composed of drawing data receiving module, 3D vision module, industrial control edge computing module, scanning motion control module, and human-computer interaction tablet.

The whole process of data-driven visual quality inspection is divided into three core links: one is to obtain the BIM drawing data of the corresponding mold table; the second is to drive 3D visual scanning components to obtain actual data; Third, the two are quickly compared through the algorithm and output the quality inspection results according to the quality inspection standards.

The first link is to obtain BIM drawing data: the process is completed by the central control room system SPCI-PMES, and the component split design models output by mainstream design software such as PKPM, REVIT, PlanBAR, ZDPC and so on can be identified and analyzed.

When the mold table that binds the mold task data is transferred to the quality inspection station according to the process flow, the quality inspector selects the task to be inspected on the quality inspection tablet, and issues it to the equipment to start the quality inspection.

The second link is to obtain actual data: the device that receives the quality inspection instruction is equipped with a high-precision 3D camera, runs the scanning smoothly, and performs real-time computing and processing on the edge of the point cloud. There is no human intervention required for this process.

The last link: the edge algorithm automatically compares the drawing data and visual data, outputs the quality inspection results, and presents the tablet in real time in a graphical way. The information includes pictures of hidden inspections, visual results, and comparison results with drawings. Among them, the green line indicates that it is qualified, the red line indicates that it is missing/redundant, and the yellow line indicates that the dimensional accuracy does not meet the quality inspection standards.

According to the results of the system quality inspection, the quality inspectors will adjust and confirm on the spot, and after passing the goods, they will flow to the next process of the cloth, and if they are unqualified, the quality inspection can be restarted after the adjustment until they are qualified.

The 3D visual data is fused with BIM drawing data through the central control industrial software SPCI-PMES, corrects and shares the cloth data, and updates it to the fabric equipment to achieve accurate and intelligent fabric.

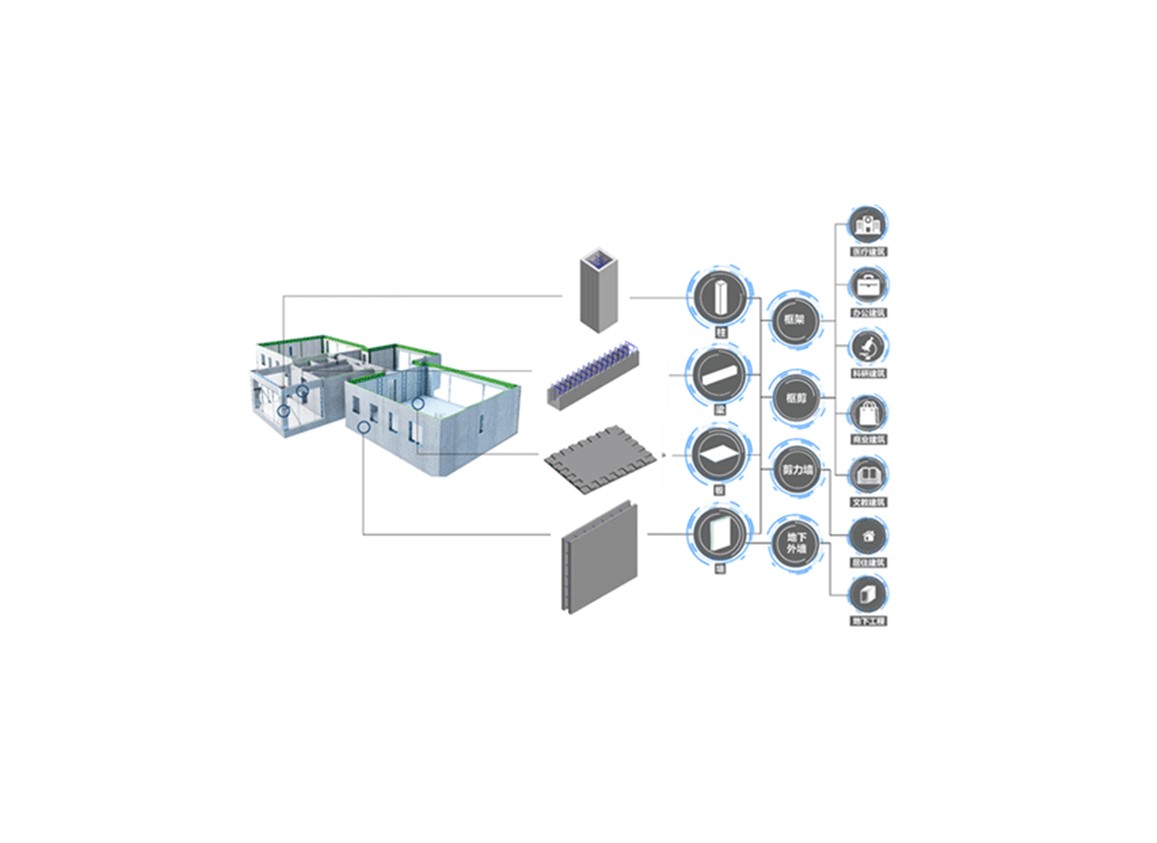

The system can realize the intelligent quality inspection of superimposed floor slabs and SPCS wall panels, and can accurately inspect the contour size, embedded position and size of the components, the position size of the reinforcement truss, the position of the reinforcement mesh/cage, etc., with an accuracy of ±2mm, and a cycle time of 3min/formwork, supporting the deployment of new production lines and the transformation of existing production lines.

These innovations and practices of Sany Construction not only promote the development of prefabricated buildings, but also provide new ideas and solutions for the digital transformation of the entire construction industry. With the continuous progress of technology and the deepening of application, the future construction industry will be more intelligent and automated, providing more efficient, environmentally friendly and safe building products and services for the society.

SPCS structural system

Structural standardsRecommended products

Related testimonials

Sany Construction Engineering launched a cement-based demolition-free floor deck production line

2025.05.20

Sany Construction Engineering made a blockbuster appearance at the Changsha International Construction Machinery Exhibition

2025.05.19

See you in 2 days at the 2025 Changsha International Construction Machinery Exhibition!

2025.05.13

0 comments