Sany Heavy Electro-hydraulic Control System was certified by Minehong

2025.04.24

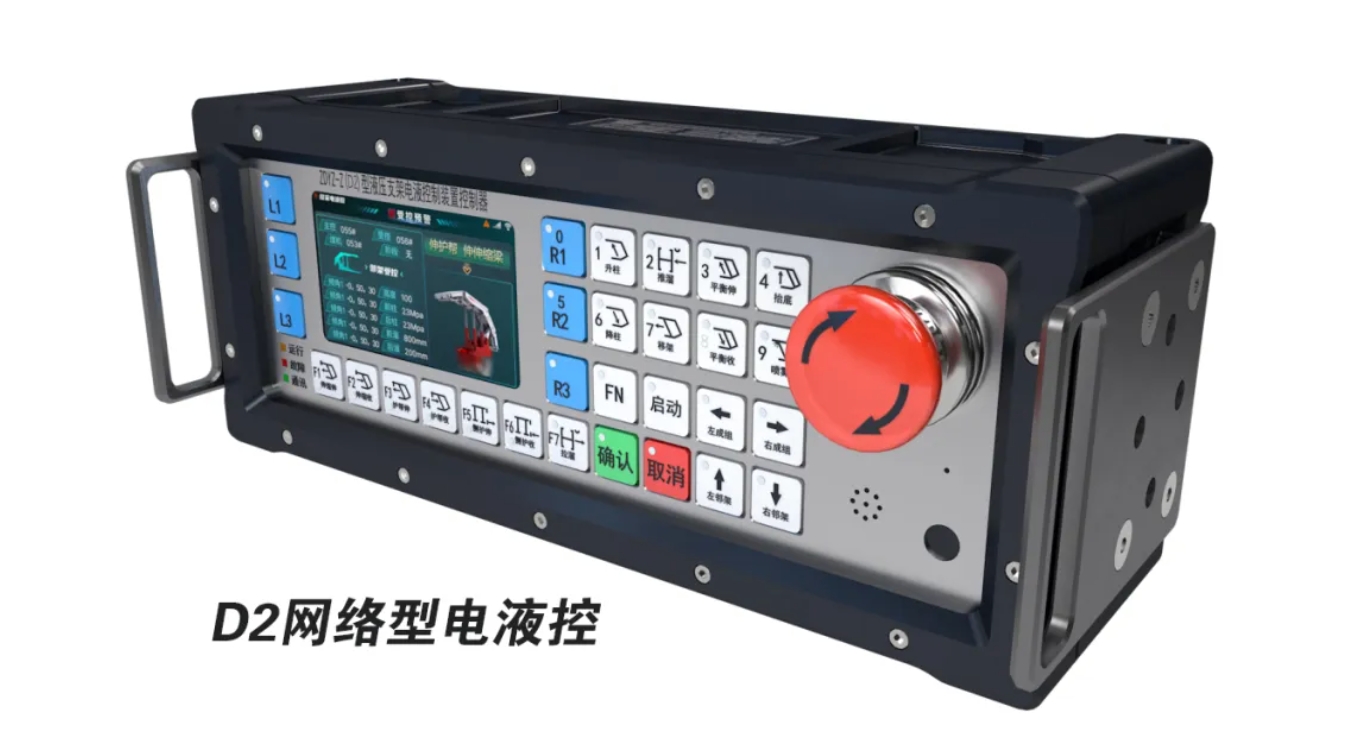

Recently, the ZDYZ-Z (D2) electro-hydraulic control system independently developed by Sany Heavy Equipment has successfully passed the strict test of the Key Laboratory of Mine Interconnection Innovation of the State Bureau of Mining and Mining, and officially obtained the Mine Hung Compatibility Test Certification. The acquisition of the certificate is on TrinityHydraulic supportThe successful integration of electro-hydraulic control products into Huawei's Kuanghong system is a milestone. The R&D and certification of this product will effectively promote the development of the core products of Sany Coal Machinery Equipment Sector to high-end, intelligent, independent and controllable, and better meet the requirements of intelligent mine construction.

Technological breakthrough industry-leading

ZDYZ-Z (D2) electro-hydraulic control system adopts optical fiber gigabit ring network architecture, and innovatively realizes the deep integration of six functions of working face control, data acquisition, video surveillance, voice communication, personnel positioning and 5G network. The system has been applied on a large scale in major mining areas across the country, significantly improving the intelligent level of coal mining.

Ecological co-construction and coordinated development

As one of the first batch of enterprises to be awarded the "Mine Hung OSV Ecological Partner" in August 2024, Sany Heavy Equipment has passed the Mine Macro certification this time, further consolidating its leading position in the field of coal mine intelligence. This certification not only verifies the technological advancement of the product, but also promotes the industrialization process of domestic independent and controllable intelligent equipment.

Remarkable results have been achieved in improving quality and efficiency

The fully mechanized mining automation system is the core component of the intelligent coal mining face production system, which realizes the comprehensive management and control of the three machines of the working face, the emulsion guarantee system, the power supply and distribution system, the video monitoring system, the perception and positioning system and other auxiliary systems. Sany Heavy Equipment fully mechanized mining automation system can be deeply customized according to different geological conditions, which effectively solves the core problems of high safety risk, low production efficiency and high labor intensity in traditional mining. Practical application data show that the system can improve mining efficiency by more than 30%, reduce the number of operators by more than 50%, and has been sold more than 100 sets in the country, creating significant economic and safety benefits for coal mining enterprises.

Facing the future, Sany Heavy Equipment will continue to adhere to the innovation-driven development strategy and work together with industry partners to jointly promote the construction of intelligent mines.

Rail-mounted container gantry crane automation

Rail-mounted container gantry craneRecommended products

0 comments