The joint AI training of Sany Heavy Equipment, BPIT Group and Northeastern University was successfully concluded, opening a new chapter in industrial intelligence

2025.04.28

On April 24, 2025, the special training activity of "AI Pilot, Industrial Intelligence Empowering the Future" jointly sponsored by the Digital Intelligence Headquarters of Sany Heavy Equipment, the National Frontier Science Center for Industrial Intelligence and System Optimization (DAO Laboratory) of Northeastern University and BPIT of the Group was successfully held in Shenyang.

The event was presided over by Shi Pengfei, the supervisor of the Digital Intelligence Headquarters of Sany Heavy Equipment, and Dr. Ji Dong of the DAO Laboratory of Northeastern University and Dr. Xun Qifeng, Assistant Director of the Data Intelligence Department of the Process Informatization Headquarters, as the keynote speakers.

School-enterprise collaborative innovation to build an industrial intelligent ecology

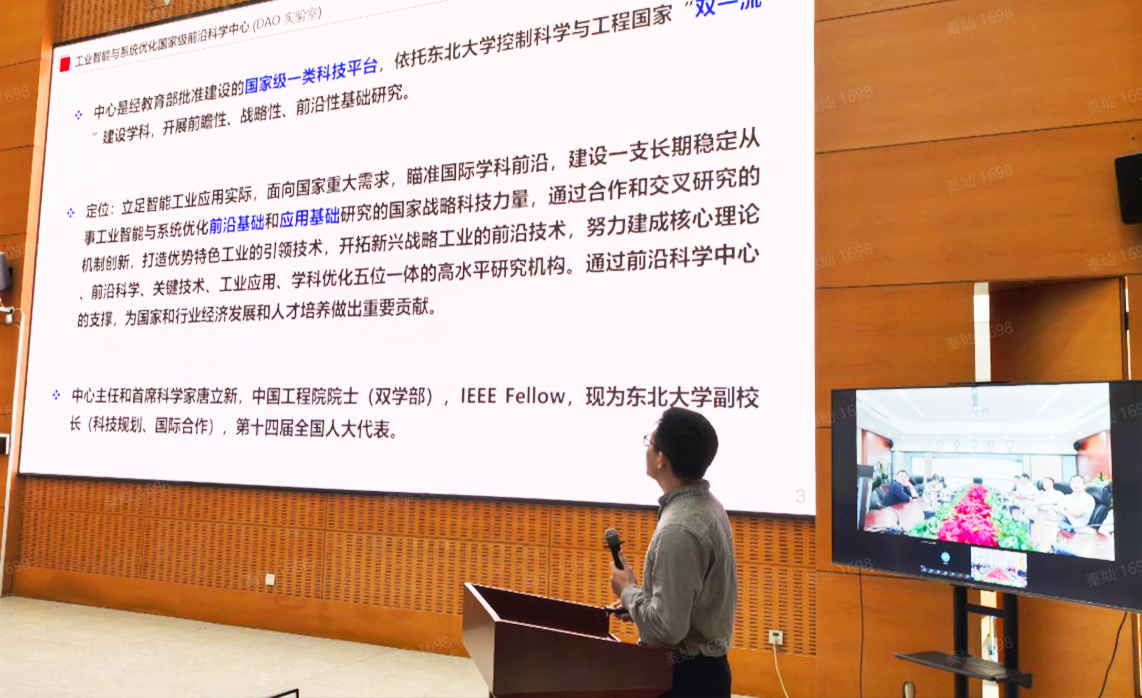

This training is a milestone for Sany Group BPIT, Sany Heavy Equipment Division and Northeastern University to deepen school-enterprise cooperation. As a national first-class science and technology platform, the DAO Laboratory of Northeastern University has long been committed to cutting-edge research in the field of industrial intelligence and system optimization relying on the "double first-class" disciplines of control science and engineering.

During the event, Dr. Ji Dong systematically shared the joint R&D projects of the laboratory in multiple business fields such as Sany Heavy Equipment Manufacturing, Marketing, R&D, and Technology with the theme of "Large Model Empowering Industrial Scenario Practice", and gave a detailed introduction and explanation of the current project progress and technical route.

Dr. Ji Dong pointed out that the core of school-enterprise cooperation lies in the "deep integration of academic theory and industrial scenarios". In view of the efficiency bottlenecks and data fragmentation problems existing in complex industrial scenarios, the two parties have realized intelligent transformation in key business processes through the research and development of retrieval enhancement generation technology and dynamic prediction models, significantly improving the efficiency of information processing and decision-making. In the field of multi-modal industrial data analysis, by integrating multi-dimensional information such as equipment working conditions and market dynamics, an innovative algorithm framework is built to effectively optimize inventory management and resource allocation capabilities, and provide technical support for the digital upgrading of industrial scenarios.

Dr. Xun Qifeng emphasized that "AI technology needs to take root in industrial scenarios and solve real problems" from the perspective of enterprise strategy. He said that through the introduction of large-scale model technology, breakthroughs can be achieved in fault diagnosis, process optimization, supply chain management and other links in the future. It will further rely on the cutting-edge scientific research capabilities of Northeastern University to deepen joint research in the fields of intelligent decision-making and digital twins, and promote "AI + manufacturing" from single-point innovation to full-chain upgrading.

Technology empowers scenarios and explores the future of industrial models

During the event, the two parties disclosed the research and development progress of the multi-agent collaborative industrial visual tracking system for the first time. By deploying multi-modal AI Agent, combining deep learning and dynamic object tracking technology, the platform realizes the automation of the whole process of sorting and reporting, reduces the manual intervention rate by 70%, and provides a new paradigm for the flexible upgrading of traditional manufacturing industry.

In addition, the two sides also conducted in-depth discussions on topics such as "integration of large models and small models" and "industrial data assetization", providing the industry with the landing experience of "technology + scenario" two-wheel drive.

As a leading enterprise in high-end equipment manufacturing in China, Sany Heavy Equipment has always regarded technological innovation as its core competitiveness. The cooperation with Northeastern University not only provides technical support for the implementation of the industrial model, but also creates a collaborative model of "production, education, research and application" integration.

In the future, the two parties plan to jointly build an industrial intelligence joint innovation center, focusing on intelligent operation and maintenance, green manufacturing, digital twins and other directions, promoting more scientific research achievements into productivity, and helping China's intelligent manufacturing move towards the high-end of the global value chain.

At the end of the event, Shi Pengfei, the supervisor of reloading digital intelligence, concluded: AI is not a replacement, but an empowerment; The in-depth collaboration between enterprises and universities will accelerate the two-way rush of technologies and scenarios, so that industrial intelligence can truly become a new engine for high-quality development.

The successful holding of this training marks a new stage of school-enterprise cooperation between Sany Heavy Equipment and Northeastern University, and also sets a benchmark example of "intelligent transformation and digital transformation" for the industry.

Rail-mounted container gantry crane automation

Rail-mounted container gantry craneRecommended products

automation

Rail-mounted container gantry crane automationRelated testimonials

Sany Heavy Machinery's first overseas factory localized supply chain return training ended successfully!

2025.06.26

Good news! Sany Heavy Equipment won 2 "China Patent Awards"!

2025.06.25

The acceptance ceremony of Shanxi Shanxi Huifeng Xinxing Coal Industry Co., Ltd.'s intelligent fully mechanized mining machine was held in Sany Heavy Equipment Shenyang Industrial Park

2025.06.24

0 comments