Ma Yunfei, chief engineer of Sany Construction, delivered a keynote speech at the 2025 Industrial Internet Intelligent Construction Overseas Conference

2025.07.10

Trinity Builders

Recently, the 2025 Industrial Internet Intelligent Construction Overseas Conference and the establishment ceremony of the Industrial Internet Intelligent Construction Special Committee of the China Maritime Association were held in Beijing. The conference was hosted by the China Association for Overseas Development of Industry (hereinafter referred to as the "China Overseas Development Association"), organized by the China Maritime Association Industrial Internet Intelligent Construction Special Committee, Beijing Jianyi Investment and Development (Group) Co., Ltd., and Cesium Pradesmium Technology Co., Ltd., and co-organized by the China International Engineering Consulting Association, the Construction Industry Group of the Industrial Internet Industry Alliance, and the Belarusian National Design and Research Institute. Relevant leaders of Zhongnan Architectural Design Institute, Sany Group and other enterprises attended the meeting. With the theme of "Sail to the Sea and Draw a New Blueprint for Global Industrial Internet Cooperation", the conference brought together global political and business elites and industry leaders to explore the international upgrading path of "Built in China". Ma Yunfei, assistant to the president of Sany Group and chief engineer of Sany Construction, delivered a keynote speech on "Intelligent Manufacturing Empowers Intelligent Construction to Go Overseas", systematically expounding Sany's strategic practice and vision of promoting the global implementation of China's construction technology with intelligent manufacturing as the engine.

The conference adopts an innovative form of online and offline integration, and the atmosphere of the offline conference is warm, and the online metaverse live broadcast has attracted much attention. Representatives of envoys to China, overseas business elites, representatives of domestic governments and multi-industry associations, technical management elites from relevant units in the field of construction and universities and research institutes, software and hardware manufacturers and mainstream media representatives gathered together to participate in the event.

In Ma Yunfei's speech, he pointed out that in the context of the deep integration of "Digital China" and the "Belt and Road", "intelligent manufacturing is the nuclear power for intelligent construction to go overseas". Relying on the group's 37 years of experience in high-end equipment manufacturing, Sany Construction has built a trinity technical ecology of "SPCS structural technology system + intelligent equipment + cloud platform".

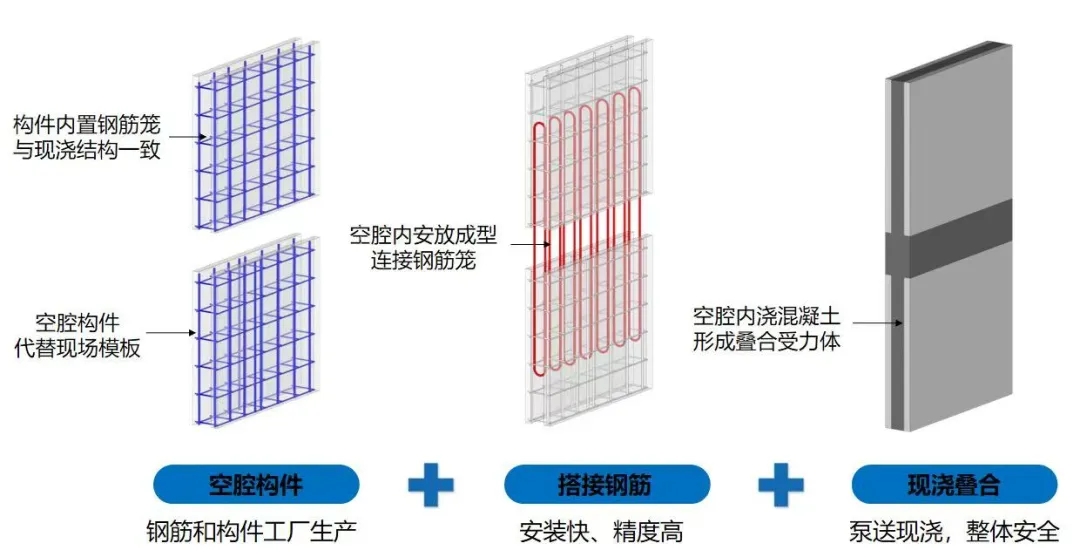

SPCS structural technology system: based on the technical route of "cavity wall columns, equivalent heterogeneity, corner post-pouring, in-plane operation + industrialized electromechanical and prefabricated decoration", relying on the Zhuxiang cloud platform, online collaborative design, production, and construction data, data-driven assembly line intelligent production, to achieve industrial-grade manufacturing quality. Compared with the European double skin wall system, the SPCS structural technology system eliminates the steel truss and the amount of steel bar is more economical. The whole cage is safer; The structure of walls, columns and beams is integrated, and the factory production is intelligent. It has the characteristics of light weight, good waterproof performance, no plastering on the wall, and good apparent quality, so as to realize the structure as a building.

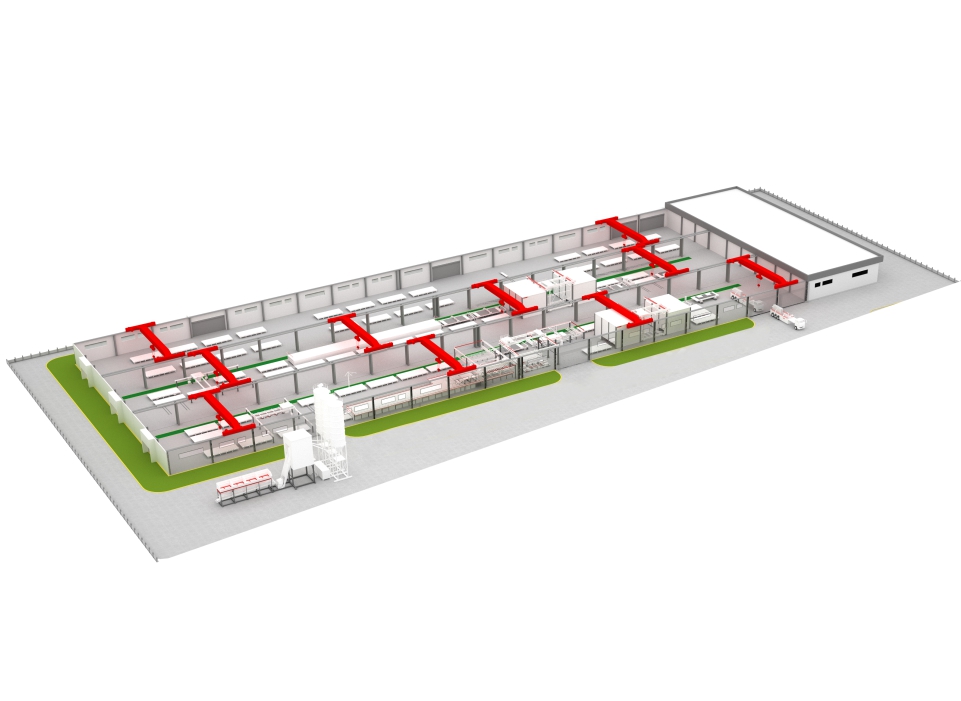

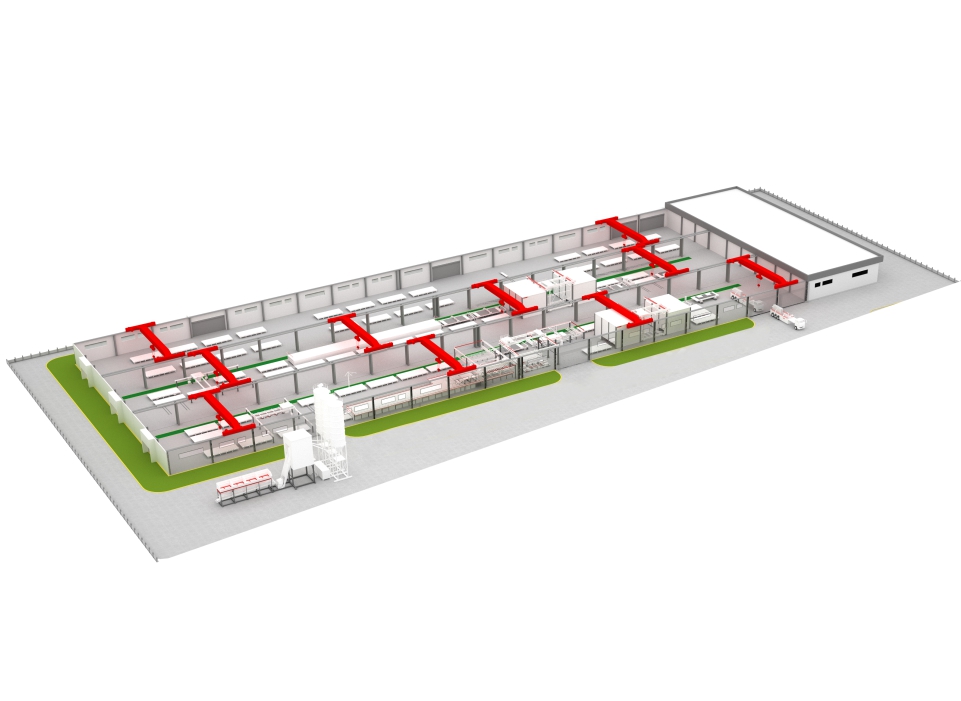

Intelligent equipment: Sany Construction provides PC equipment, AAC equipment, steel bar equipment, and green recycling equipment for the industry.Mold fixtureand other intelligent equipment, among which the intelligent PC production line has a domestic market share of more than 50% for many years. The production line adopts modular robot clusters, integrates AI algorithms, and automates the whole process of production through self-developed industrial software and data-driven equipment, covering walls, beams, plates, and columns with a full component system, and the production efficiency is 20% higher than the industry average. Taking the Malaysian PC factory as an example, the single-line labor was reduced by 40%, and the pass rate of mesh production increased by 30%, supporting the overseas engineering record of "67 terraced houses delivered in 5 months".

Zhuxiang Cloud Platform: As the "digital brain" of intelligent construction, the Zhuxiang Cloud Platform opens up the whole process of design, production, and construction, and realizes online collaboration of the whole life cycle, key roles, and key elements. In the design, production, and construction states, the whole process of prefabricated components can be controlled one by one. Through online procurement, digital twin, real-time monitoring and other functions, the comprehensive project management efficiency has been increased by more than 30%, and all elements can be managed online to assist in decision-making. At present, the platform has served more than 6,000 projects, shortening the construction period by 8%-10% on average.

In terms of global layout, Ma Yunfei emphasized that Sany Construction is completing "from equipment to industrial empowerment", adopting the DPI+E3 overseas strategy: with design, production, and installation as the core, supporting equipment, education, and entrepreneurship services to help overseas partners localize their operations. The 174 apartment project in Jeddah, Saudi Arabia, uses a 100% assembly rate, verifying the high adaptability of the model.

During the conference, the China Maritime Association Industrial Internet Intelligent Construction Special Committee was officially established. As a founding member, Sany Construction will rely on the special committee to accelerate the global implementation of China's intelligent construction technology, standards and services, and reshape the new territory of the world's construction industry with the power of digital.

Sany PC integrated automated production line

SPCE smart PC equipmentRecommended products

PC production line

Sany PC integrated automated production lineRelated recommendations

【Jiajia Broken Thoughts】Anti-involution alliance Jiajia will show you how Sany Mobile counterattack crushing station violently hits industry barriers!

2025.07.23

Hunan Satellite TV's "Hunan News Network" Hunan Construction Machinery Strengths in the International Market Sany Road Machine Hard Core Strength Attracts Attention

2025.07.22

The first Sany Road Machinery Global Customer Summit Road Surface Machinery Network immersive exhibition

2025.07.22

0 comments