Sany Heavy Industry Sany Heavy Industry Co., Ltd. (SH:600031)

Trinity International Sany International (HK:00631)

Sany Renewable Energy Sany Renewable Energy (SH:688349)

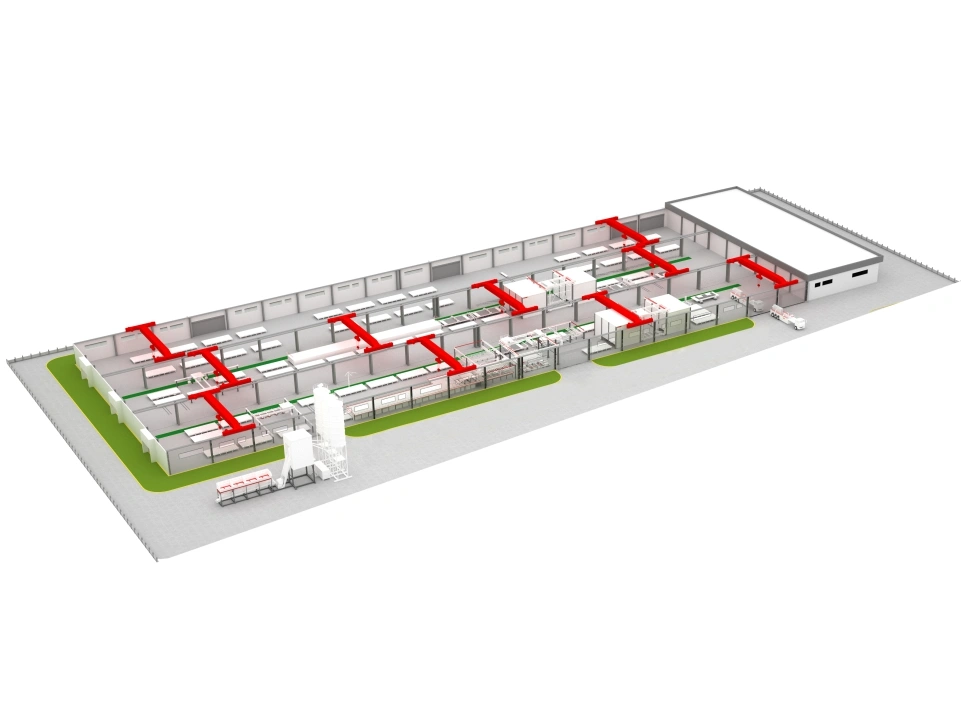

PC production line

SPCE smart PC equipment

Production of all kinds of PC prefabricated components

Fully automatic circulation

Lean manufacturing high-end R&D

Applicable working conditions

Product BrochureProduct Details

Construction case

Performance parameters Product selling point

Producible components

All board components such as exterior wall panels, interior wall panels, laminated floor panels, partition wall panels, air conditioning panels, etc

Management system

PCM Component Management System PMES Production Management System

Equipment composition

Central control system, mold table circulation system, mold table pretreatment system, cloth system, maintenance system, demoulding system

Product Use:

Production of all kinds of PC prefabricated components

Product Features:

Fully automatic circulation

Product Advantages:

Lean manufacturing high-end R&D

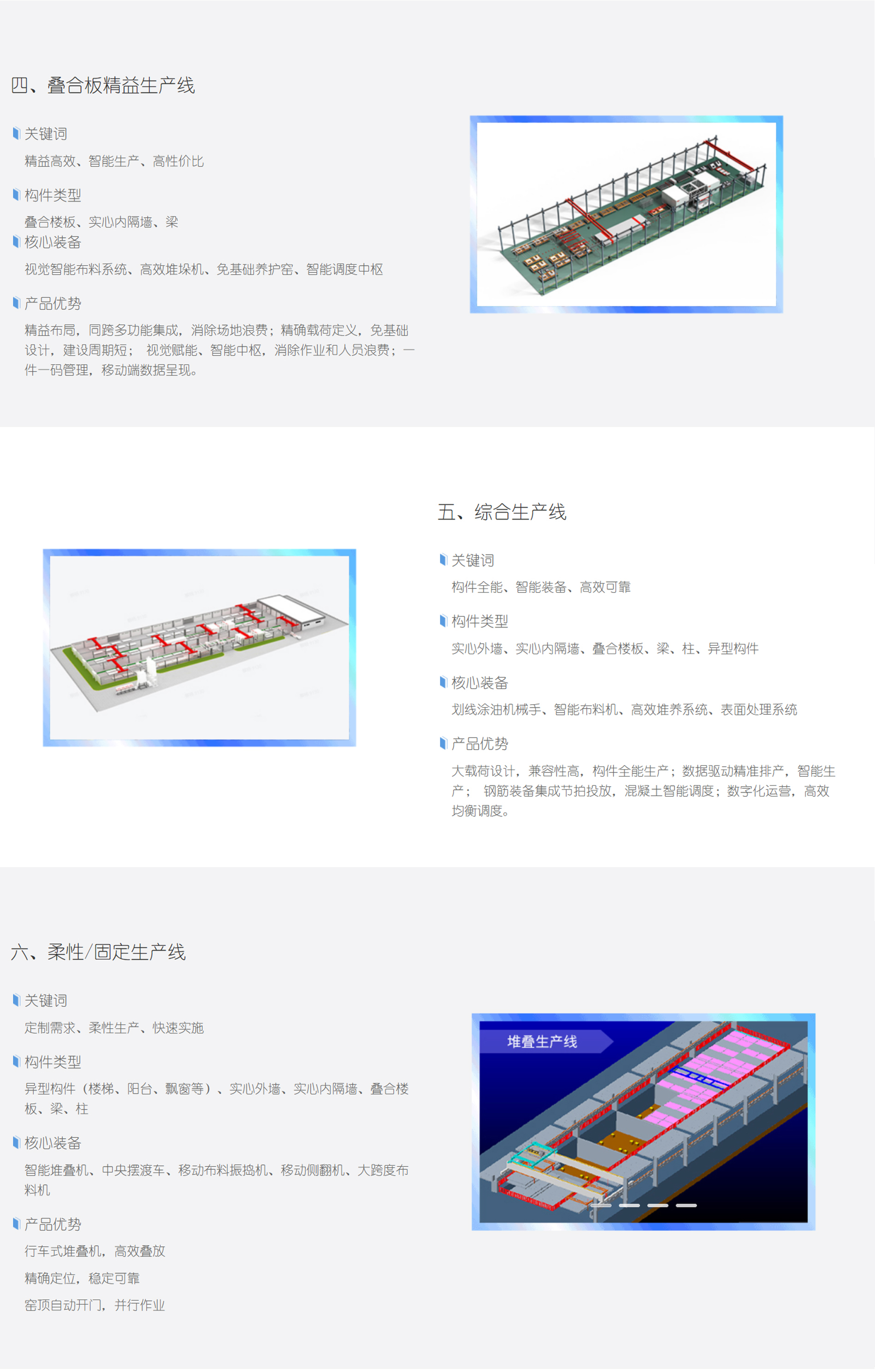

1. Digital technology

PCTEAM platform online collaborative design, production, construction data. Mainstream BIM software realizes efficient design and splitting of components, SPCI industrial software directly drives complete sets of PC intelligent equipment for automatic production, PCM component management system realizes automatic scheduling of production plans, and information management of components in the whole life cycle of one piece and one code. 30% increase in overall operational efficiency.

2. Intelligent equipment

With the core of the complete set of intelligent PC equipment with the core of the formwork removal robot, flexible steel bar intelligent system, visual quality inspection, intelligent cloth vibration, concrete scheduling, high-precision flip clamping, and efficient stacking, the complete set of intelligent PC equipment digital-drive automatic JIT (beat) production, the demand for operators is reduced by 40%.

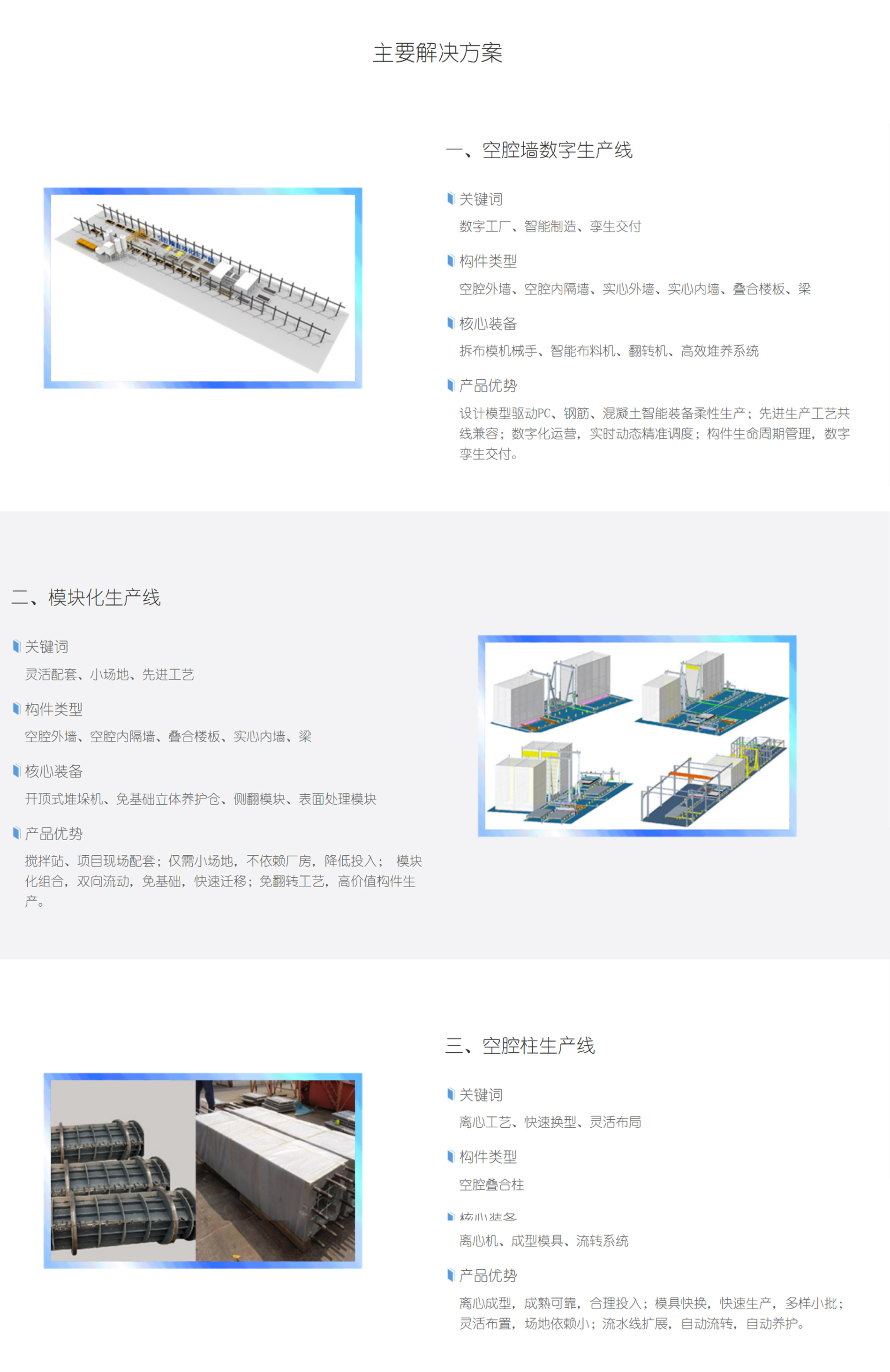

3. Solution

Provide comprehensive solutions for platform collaboration, resource sharing, process layout, intelligent equipment, standard operation, intelligent operation and maintenance, upgrading and transformation, alliance factory cooperation mode, and professional team to guide operations, so as to empower customers to form mature production profitability with high output and high returns. Customers achieve a high return on investment and achieve rapid success.

4. Worry-free delivery

Efficient and systematic R&D capabilities, rich product solutions, strong advanced manufacturing capabilities, self-owned professional installation team, and sound service network architecture to meet customer standard needs or customized needs, and achieve high-quality delivery (standard line 35+40 days), the whole process is worry-free.

PCTEAM platform online collaborative design, production, construction data. Mainstream BIM software realizes efficient design and splitting of components, SPCI industrial software directly drives complete sets of PC intelligent equipment for automatic production, PCM component management system realizes automatic scheduling of production plans, and information management of components in the whole life cycle of one piece and one code. 30% increase in overall operational efficiency.

2. Intelligent equipment

With the core of the complete set of intelligent PC equipment with the core of the formwork removal robot, flexible steel bar intelligent system, visual quality inspection, intelligent cloth vibration, concrete scheduling, high-precision flip clamping, and efficient stacking, the complete set of intelligent PC equipment digital-drive automatic JIT (beat) production, the demand for operators is reduced by 40%.

3. Solution

Provide comprehensive solutions for platform collaboration, resource sharing, process layout, intelligent equipment, standard operation, intelligent operation and maintenance, upgrading and transformation, alliance factory cooperation mode, and professional team to guide operations, so as to empower customers to form mature production profitability with high output and high returns. Customers achieve a high return on investment and achieve rapid success.

4. Worry-free delivery

Efficient and systematic R&D capabilities, rich product solutions, strong advanced manufacturing capabilities, self-owned professional installation team, and sound service network architecture to meet customer standard needs or customized needs, and achieve high-quality delivery (standard line 35+40 days), the whole process is worry-free.

Due to the continuous update and progress of technology, the differences between technical parameters and configurations and the actual product shall be subject to the actual product; In addition, the machine on the picture may include additional equipment.

Parameter comparison

Recommended products

See them all