Sany Heavy Industry Sany Heavy Industry Co., Ltd. (SH:600031)

Trinity International Sany International (HK:00631)

Sany Renewable Energy Sany Renewable Energy (SH:688349)

Intelligent mining|Sany fully mechanized mining automatic control system

2021.11.27

Trinity reloaded

As China's coal production has gradually entered the stage of intelligent mining, the construction of smart mines and green mines has become an industry trend.

Sany Intelligent Mine, a subsidiary of Sany Heavy Equipment, independently developed itElectro-hydraulic control of hydraulic support,ShearersThe fully mechanized mining automation control system integrates functions such as inertial navigation, precise positioning of personnel and equipment, video AI analysis of fully mechanized mining face, remote data acquisition and monitoring, etc, leading the industry to a new stage of intelligent development.

fully mechanized mining face automatic control system,With the centralized control center of the groove as the core, the working face video, Ethernet, audio, perception, and remote control are the foundationsThrough logical operation and adaptive decision-making, the centralized automatic control of the entire fully mechanized mining face is realized, so as to ensure the coordinated, continuous, efficient and safe operation of all equipment, and liberate workers from the working face to the relatively safe groove and ground.

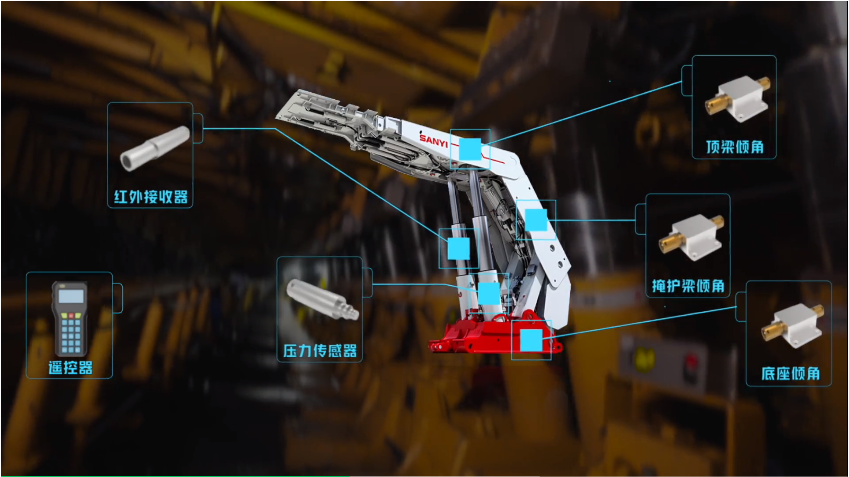

Electro-hydraulic control system

The electro-hydraulic control system is a complete set of equipment for safe, efficient and automatic control of hydraulic supports, a key technology and equipment to realize the automation and intelligence of fully mechanized coal mining, and a key foundation for realizing a less manned working face and an unmanned working face.

Technical features:

· The controller integrates UWB high-precision positioning module, and the positioning accuracy of working face personnel and shearer is as high as 0.2m;

· Breaking the tradition, the working face integrates a CAN link with the centralized control center along the groove, no relay equipment, high real-time data, and ≤ communication delay of 20ms;

· Relying on the multi-field technology accumulation of Sany Group, it is compact in size, high in reliability and excellent in quality.

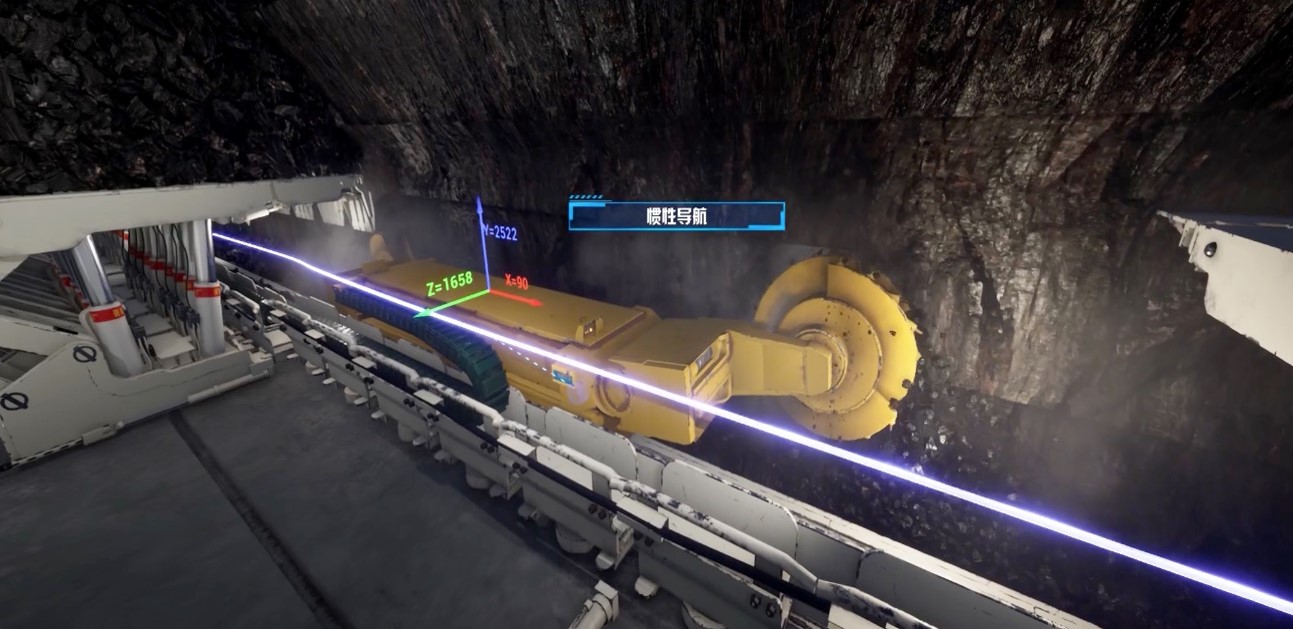

Shearer system

The military optical fiber inertial navigation installed on the shearer solves the problems of cutting starting point calibration, cutting curve depiction, support adjustment and control, etc., and can provide accurate data basis for underground three-dimensional spatial positioning and related operations.

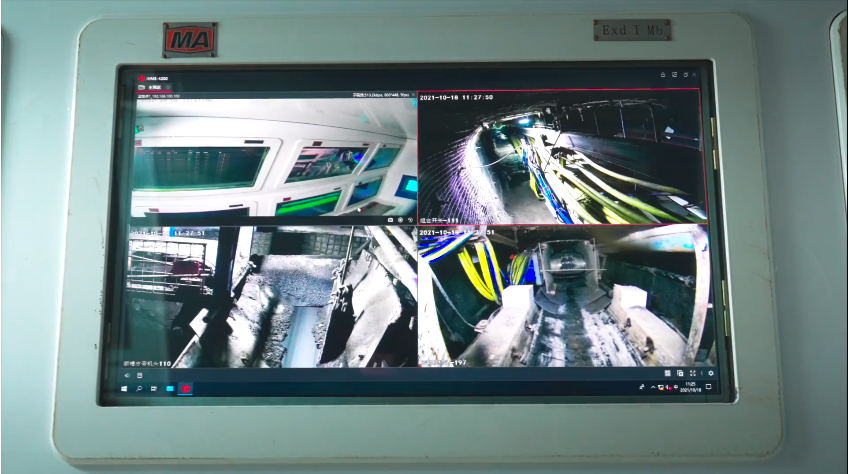

Work face visualization system

By installing a high-dust removal camera and thermal imager on the working face, supplemented by AI visual recognition with an accuracy rate of up to 97%, the underground picture can be grasped in real time to ensure the safety of people, objects, environment and equipment.

Ground dispatch center

The ground dispatching center integrates each subsystem, transmits data to the ground through Ethernet, and analyzes, diagnoses, and integrates by the ground intelligent management platform to build a digital twin ecosystem based on big data and AI algorithms, providing a strong guarantee for users' scientific production management and intelligent decision-making.

According to the requirements of the 14th Five-Year Plan for Mine Safety Production in China, all kinds of mines will be greatly reduced, and eventually unmanned mines.

Sany Heavy Equipment will conform to the industry trend and explore the new future of intelligent mining with the power of science and technology!

Recommended products

0 comments