Sany Heavy Industries Sany Heavy Industry (SH:600031)

Trinity International Sany International (HK:00631)

Trinity Renewable Trinity Renewable Energy (SH:688349)

The world's first 9020C10EV pure electric on-board pump is here!

2021.12.23

Achieving carbon peaking and carbon neutrality is a major strategic decision made by the Party Central Committee with Comrade Xi Jinping as the core to coordinate the overall situation at home and abroad. Strategic emerging industries represented by new energy, new materials, high-end equipment, new energy vehicles, etc. have made great progress.

Sany Group is committed to the transformation to "digitalization, electrification and intelligence", and has laid out dozens of products in terms of electrification.

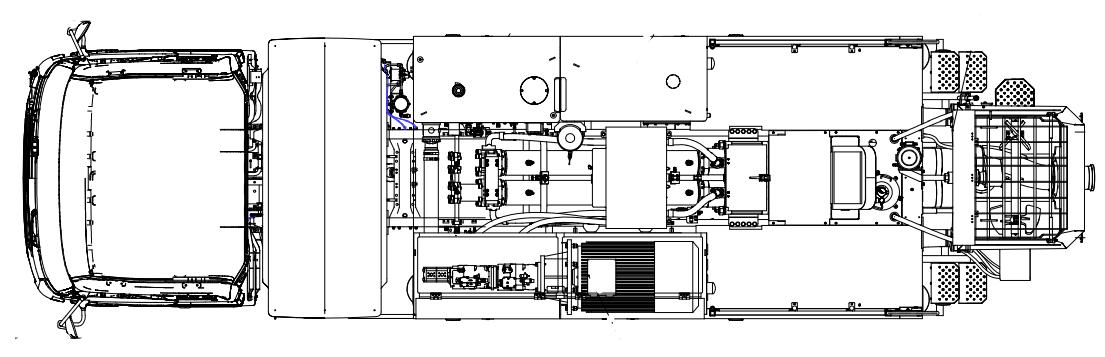

9020 pureElectric vehicle pumpIt is the world's first pure electric on-board pump newly built by Sany in response to the call for energy conservation and emission reduction, equipped with Dongfeng EQ1180GEVJ5 pure electric chassis, and the top continues to use the original 9020 reliable electric power system. The vehicle does not have a diesel engine, and the driving and pumping are all electric power, which truly achieves zero emissions and no pollution.

Pure electric chassis

Different from the traditional fuel chassis, this pure electric on-board pump is equipped with a Dongfeng pure electric chassis.The chassis motor has a rated power of 80Kw and a peak power of up to 160Kw, with strong acceleration and climbing capabilities. Equipped with a 218-degree ultra-large-capacity lithium iron phosphate battery, the cruising range can reach more than 300 kilometers, and the power consumption per 100 kilometers is only 71kWh, which truly allows customers to drive worry-free.

The vehicle's high-voltage components and power battery have been added to improve waterproof sealing and safety. Green control motors, CATL batteries, well-known brand component suppliers let you have worry-free after-sales warranty.

In addition, the electric chassis is equipped with airbag seats, automatic transmission and electric air conditioning, which greatly improves handling and comfort compared to traditional chassis.The electric air conditioner is powered by a power battery, and when the air conditioner is turned on, the cooling module fan noise is only 69dB(A), allowing you to enjoy the coolness quietly in the hot summer.

The upper configuration is strong

In order to ensure the reliability of the upper assembly, the main components of the upper installation still inherit the genes of the original 9020 electric pump.The maximum outlet pressure can reach 20Mpa, the maximum displacement can reach 90 cubic meters per hour, and the maximum number of reversals can reach 24 times.The 132Kw high-power motor of the original 9020 electric pump is used, equipped with a 190+130 Rexroth main oil pump.The upper layout is reasonably optimized, the motor adopts the form of longitudinal arrangement, the hydraulic oil tank and the water tank are arranged on the same side, the vehicle has good balance, and the convenience of maintenance is also greatly improved.

Energy saving and environmental protection

The whole vehicle is a new energy vehicle, which can be given a green card and is not restricted by environmental protection regulations, allowing you to travel unimpeded.The electricity consumption per 100 kilometers is only 71 degrees, and the charging cost per 100 kilometers is about 71 yuan. The fuel consumption of the traditional fuel vehicle pump is about 28L per 100 kilometers, and the driving cost of 100 kilometers is about 190 yuan, and the driving cost of the electric chassis is reduced by 63% compared with the fuel chassis.

The average pumping of concrete on top consumes about 2 kWh of electricity, and the cost of pumping concrete per square meter is about 2 yuan per square meter according to the electricity cost of 1 yuan/kWh. while the average pumping of traditional fuel vehicle pumps is about 0.5L of diesel per square concrete, so the cost of pumping concrete per square meter is about 3.4 yuan.

The cost of electric pumping is about 40% lower than that of diesel pumping. According to the annual pumping volume of 60,000 square meters, it can save 80,000 yuan in fuel costs and more than 5,000 yuan in urea per year, and can avoid the high cost of diesel purchase for customers. Not only that, but it can also reduce carbon emissions by 21.5 tons per year.

High reliability

Since the vehicle rolled off the production line in the first half of 2021, it has gone through half a year of rigorous road tests and pumping performance tests, and all performances have been fully verified.

Recommended products

0 comments

0 comments