Construction project of the core R&D base of the National Synthetic Biotechnology Innovation Center

2021.04.30

Construction time

Construction site

The type of project

earthwork

Device type

Trinity Construction

The construction project of the core R&D base of the National Synthetic Biotechnology Innovation Center is a national key project, ensuring the Luban Award for China Construction Engineering. Project D2~D5 adopts SPCS prefabricated structural system,The use of SPCS cavity prefabricated walls, superimposed floor slabs and other prefabricated components, the assembly rate of 51%, is the first SPCS structural system landing project in Tianjin, with important demonstration significance.Area D is the supporting service area, the main function of the tower building is the scientific research room, and the main function of the podium building is the canteen, sports and fitness and supporting service room. D2~D5 adopts SPCS prefabricated structural system, with an application area of 26,000 square meters, all of which have 11 floors above ground and 1 floor underground. Building height: 33~35 meters. All adopt SPCS prefabricated shear wall structural system, using SPCS cavity prefabricated shear wall, steel truss superimposed floor slab, prefabricated staircase, ALC prefabricated slats and other components, SPCS cavity prefabricated shear wall is applied in 3 to 11 floors, steel truss superimposed floor slab is applied in 2 to 11 floors, according to the national standard "Prefabricated Building Evaluation Standards", the assembly rate reaches 51%.

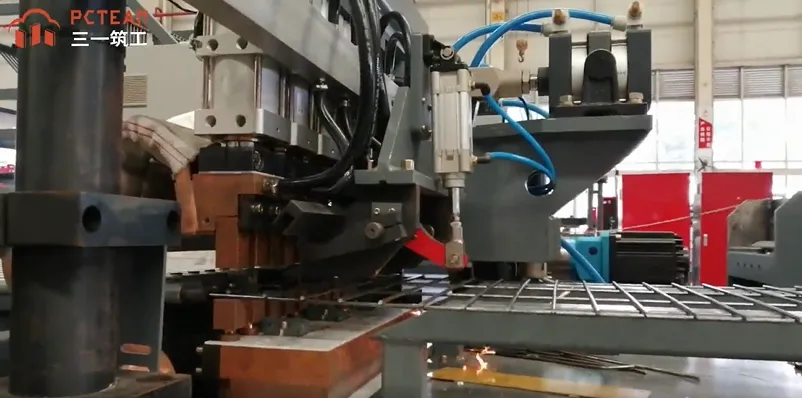

The SPCS double-sided superimposed shear wall structure adopts a superimposed shear wall structural system with welded steel mesh. A breakthrough is made in proposing a new type of superimposed shear wall structure and other superimposed components and related connection forms. This structural system has the following innovative advantages:

(1) The wallboard is mechanically welded with steel mesh structure, and the end does not need to be reinforced, which can realize the needs of large-scale industrialization and automated production, save labor, and reduce comprehensive production costs;

(2) The prefabricated part not only participates in the force but also serves as the formwork, which can realize the installation of the formwork without external formwork, which greatly reduces the workload of on-site reinforcement and formwork, the cross-operation of various types of work and the amount of on-site labor, and the construction is efficient and convenient;

(3) The components are light in weight, easy to transport, hoist and install;

(4) The system adopts a reliable and easy-to-inspect steel lap connection method, which replaces the grouting sleeve connection and grout anchor connection commonly used in prefabricated buildings at this stage and is subject to the on-site operation level, and the quality, safety and control are controllable.

In order to improve the construction efficiency and construction quality, and realize the digitization and visualization of construction management, the project adopts the prefabricated construction management system built by Sany Construction - Zhuxiang Easy Hoisting, which provides on-site hoisting construction management and BIM twin delivery services for the project in the form of a lightweight WeChat applet.

Next article: Tight oil fracturing construction in Changqing Oilfield