2019 World Premiere丨Sany Unmanned Intelligent Paving and Compaction Construction Exploded on Shanghai Beach (Shanghai Zhujian Road Road Reconstruction Project)

2021.09.23

Construction time

December 2019

Construction site

Shanghai

The type of project

earthwork

Device type

Road machinery

In today's rising labor costs, intelligent and unmanned construction machinery has become the development trend of the industry, especially in the field of asphalt paving construction, the construction party is full of expectations for the intelligent and unmanned driving of asphalt pavers, rollers and other equipment. On December 3rd, this expectation became a reality in Shanghai!

On-site construction video of Sany unmanned intelligent road machinery and equipment

On December 3, 2019, the "Lean Construction, Smart Future" - Unmanned Intelligent Asphalt Paving and Compaction Construction Technology Exchange Conference was held in Shanghai Zhujian Road (Qingpu Minhang District Boundary - Planning Kaixing Road) Road Reconstruction Project, and the construction site adopts the unmanned intelligent asphalt paving and compaction construction equipment and complete sets of technology jointly developed by STEC Road and Bridge Group, Sany Heavy Industry and Shanghai Beidou Platform Company.

Sany unmanned intelligent paving and compaction construction site

Group photo of Sany staff at the construction site

At the construction site of the road reconstruction project of Zhujian Road (Qingpu Minhang District Boundary - Planning Kaixing Road), a Sany unmanned paver and two Sany unmanned road rollers formed a fleet to cooperate with the construction of the road paving and compaction in an orderly manner, while the cab of the three equipment was empty.

At the construction site, the author saw that the Sany unmanned asphalt paver was steadily advancing according to the pre-set route, and the asphalt mixture used to build the road pavement was evenly laid on the ground. Two Sany driverless rollers are following closely behind, rolling back and forth on the newly paved road.

Sany unmanned paver construction site

In terms of intelligent construction, Sany paver is equipped with a 3D leveling system and an infrared temperature monitoring system, which can monitor the temperature and thickness of the entire paving pavement in real time, solve the construction quality problems that may be caused by traditional piling, steel wire and balance beams, and greatly reduce the number of construction personnel. During the entire paving process, the customers were amazed by the effectiveness and efficiency of the asphalt compaction of the equipment. The driverless operation of the paver is guided by the path planning formed by the road data, and the running trajectory of the paver can be adjusted in real time according to the paving width and boundary range, such as straight and turning.

Sany driverless paver has excellent construction results

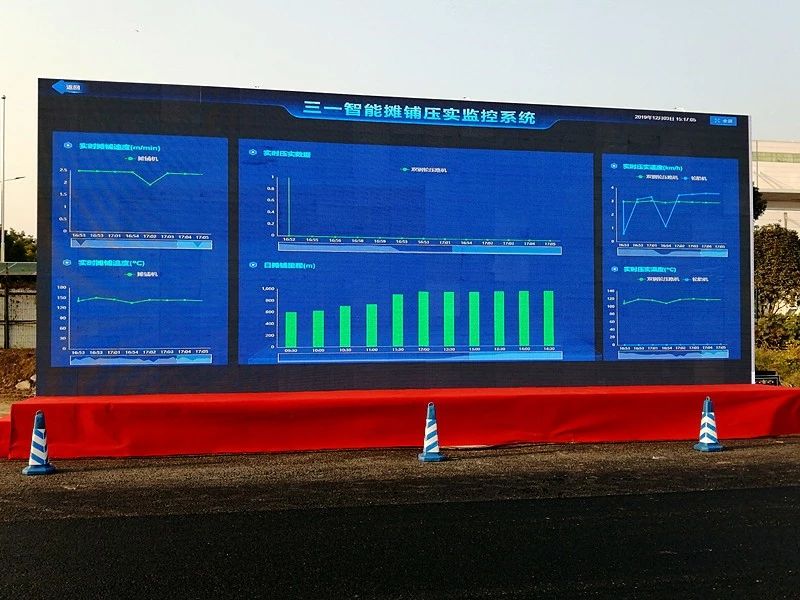

In the control room at the rear of the engineering site, the computer screen is displaying the operation and engineering parameters of the three pieces of equipment in real time, and the engineers are closely monitoring the parameters.

Engineers are closely monitoring the parameters

For construction companies, paver and roller operators are difficult to find, difficult to manage, and the wages are high, for construction companies, if only one person can manage a paver or a construction fleet. Today's unmanned intelligent asphalt paving compaction fleet is working together, making this dream a reality. Relieving the paver operator from the working environment of high temperature, heavy asphalt, vibration and high noise, the equipment manager can observe the operation of the paver in an all-round way, making the paving operation more efficient.

Compared with traditional pavers, unmanned pavers have the following outstanding characteristics: 1. Highly humanized. The operator no longer has to brave the heat wave of high-temperature asphalt radiation under the scorching sun and operate the machine in a noisy environment filled with thick asphalt smoke; Second, the construction operation is safer. Unmanned driving construction avoids the probability of paver operation accidents to the greatest extent; 3. Reduce construction costs. The paver is driverless, which requires a lower number of on-site construction personnel, which can save a considerable cost for the construction party; Fourth, the construction is more efficient. The unmanned equipment can work tirelessly 24 hours a day with high precision, so that the work efficiency is higher, and the construction effect is more stable and excellent.

On-site customers said they were very pleased to see the arrival of the era of driverless pavers. Because the current paver and other operators are not only difficult to find, but also the labor cost is getting higher and higher, especially in the field of paver construction, because the asphalt smoke on the construction site is harmful to the human body, the emergence of unmanned pavers is the general trend. In addition, the road paving operation conditions are relatively simple and closed, and the feasibility of unmanned pavers on the construction site is high and extremely necessary.

Liu Qiubao, President of Sanyi Road Machinery Research Institute

Liu Qiubao, president of Sanyi Road Machinery Research Institute, introduced that in order to allow customers to experience more easy-to-use, practical and durable intelligent pavement construction equipment and have better construction results, the research and development and functional improvement of all products are comprehensively considered from the perspective of customer needs and actual construction technology.

The complete set of intelligent construction technology for pavement machinery jointly developed by Sany with STEC Road & Bridge Group and Shanghai Beidou Platform Co., Ltd. has successfully realized the intelligent and unmanned construction operation of pavers, bringing revolutionary changes and progress to pavement paving equipment. The driverless work data can be uploaded to the cloud. According to the display on the screen, the operator can monitor and adjust in real time, which can ensure the quality more than manual paving. Our system can not only control the driving accuracy through the positioning and navigation of the Beidou satellite, but also control the positioning accuracy of the vehicle operation within 5cm. It can also be leveled with laser, which greatly improves the flatness of the road surface.

The author saw at the scene that during the construction process, the Sany unmanned roller can realize many functions such as automatic lane change, automatic driving into the construction area, automatic obstacle avoidance, etc., and accurately control the rolling speed, number of passes and lap distance. In the driverless mode, as long as the correct parameters are entered according to the on-site operating environment and requirements, Sany rollers can achieve accurate and tireless work within a certain range.

Sany unmanned roller construction site

The guests at the scene learned about the specific situation of Sany unmanned roller

The construction party said that the compaction speed, compaction times, and compaction frequency can be automatically planned and selected by Sany unmanned rollers, and the construction quality and construction speed have been greatly improved.

The large screen on site displays the construction data in real time

It is understood that Sany unmanned roller can be widely used in large dams, airports and highways, etc., and has participated in national engineering construction for many times to achieve deviation-free operation. This is the first time that Sany unmanned rollers have been officially applied to the construction of Sany pavers after participating in the construction of the high dam of the Dadu River Changheba Hydropower Station, the construction of the Xiong'an New Area, and the construction of the G105 Beijing-Olympic Line in Shandong.

Jiang Haili, Chief Engineer of STEC Shanghai Highway & Bridge (Group) Co., Ltd

Jiang Haili, Chief Engineer of STEC Shanghai Highway & Bridge (Group) Co., Ltd., said: "As a professional road construction company, we have built many high-quality asphalt pavement projects, including the Shanghai F1 track. In the past, the data of road paving compaction were in the hands of the master, and now with this set of equipment, you can grasp the first-hand data anytime and anywhere, which is of great practical significance for the development of asphalt road paving compaction technology in the future. We will continue to research and expand the application scenarios of unmanned paving compaction to different fields such as urban elevated highways and airports to meet the diverse needs of urban construction. ”

Sany unmanned rollers are under construction

Zhujian Road (Qingpu Minhang District Boundary - Planning Kaixing Road) Road Reconstruction Project starts from Minhang Qingpu District boundary in the west to planned Kaixing Road in the east, with a total length of about 3423m, the road grade is an urban secondary trunk road, the planned red line width is 40m, and the design speed is 40km/h; The construction content of the project is road engineering, bridge engineering, rain and sewage drainage pipe engineering and greening, lighting, signal lights, traffic signs and markings and other road ancillary facilities. Mr. Jiang said that in such an important project, the use of Sany unmanned paver and Sany unmanned roller with construction shows that the reliability, stability and efficiency of Sany unmanned products fully meet the requirements of the construction process.

Xiao Zhengwen, general manager of Sany Road Machinery Marketing Company, and Jiang Haili, chief engineer of Shanghai Bridge of STEC, took a group photo at the construction site

2019 is the best year for the quality of operation in the history of Sany. In the first half of this year, Sany ranked first in China's construction machinery industry with a market value of 109.5 billion yuan. Sany pavement machinery in the industry as a whole is basically flat, and even slightly declining in the background, to achieve substantial growth, pavers and asphalt stations in the national sales ranked first, rollers, graders, milling machines are in the forefront of the industry.

At the same time, Sany Road Machine has been continuously cultivating and iterating in the field of technology research and development. The construction and application of Sany unmanned paver and unmanned road roller has opened a new era of unmanned scene construction of road machinery, boosted road construction to a new intelligent and unmanned step, and continued to lead the progress of the industry.

Related testimonials

10-meter paver construction case|SAP90C-10S helps Hunan Changzhu Expressway rejuvenate!

Sany unmanned amortizer group is fully applied in the 02 bid section of Xuhuaifu Expressway

Road machine construction case | Kuitun Tacheng Street Municipal Project

UAV swarm construction case | Xuhuaifu pavement 02 bid section project