Project Practice Case丨SPCS superimposed columns were successfully applied in the basement structure of Yungu Jiayuan commercial and residential project

2021.12.09

Construction time

In 2021

Construction site

Changsha

The type of project

Housing construction

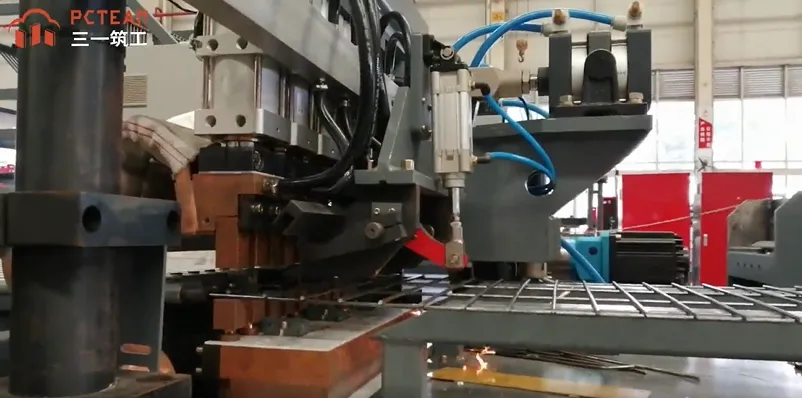

Device type

Trinity Construction

On December 3, the SPCS superimposed column developed by Sany Construction Engineering successfully completed the first installation and application in the basement structure of Yungu Jiayuan commercial and residential project, which took a crucial step towards realizing the vision of full assembly above and below ground.

Fig.1 On-site installation of the superimposed column

1. Project Overview

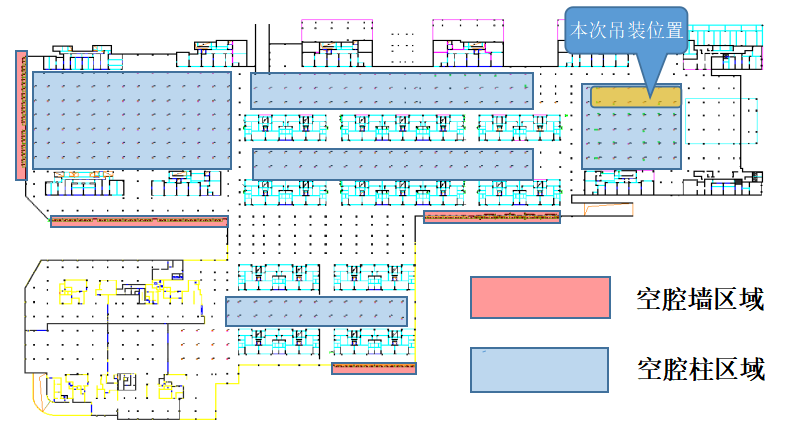

Yungu Jiayuan commercial and residential project is located in Sany Industrial City, Economic and Technological Development Zone, Changsha City, Hunan Province, south of Liangtang Road and west of Dongsi Road. The total construction area is about 240,000 square meters, of which the basement construction area is 51,000 square meters. The frame columns of the pure basement in the non-civil air defense area of this project are SPCS superimposed columns, with a total of 262 columns. A total of 12 columns were hoisted in the first batch, as shown in Figure 2.

Fig.2. Distribution of prefabricated components in the basement

Second, technical characteristics

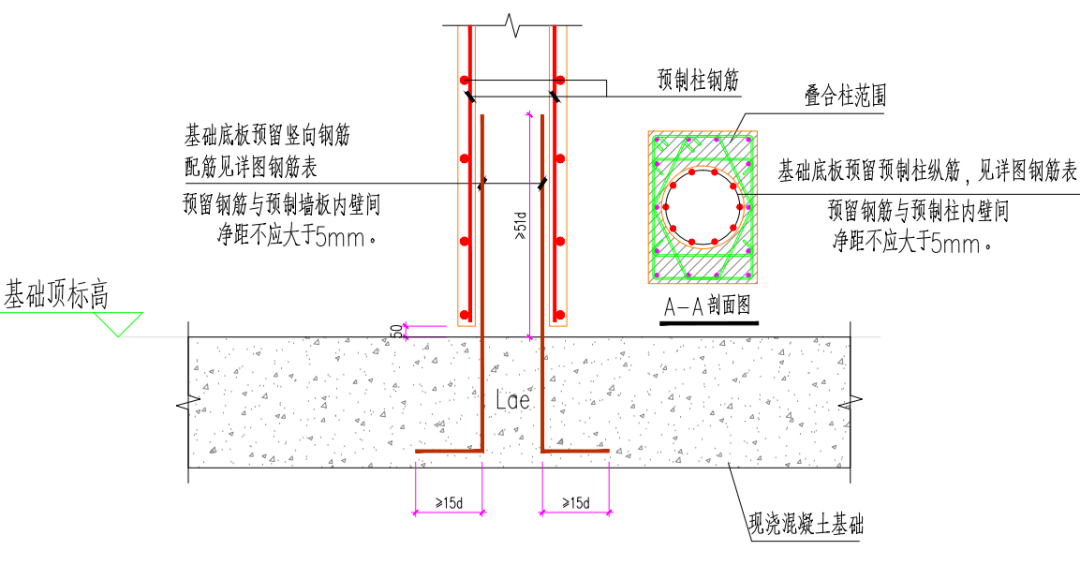

The SPCS superimposed column of this project has the following characteristics: the lower end of the component is not ribbed, the circular cavity inside the component is formed, and the construction adopts the method of cavity interpolation reinforcement connection, and the connection node schematic is shown in Figure 3. By optimizing the structural measures and simplifying the connection method, the production difficulty is greatly reduced and the installation speed of the SPCS cavity column is improved.

Fig.3. Connection diagram of superimposed column nodes

Third, the construction process

The construction process of SPCS superimposed column is as follows:

Reinforcement positioning→ oblique support, fixings, embedded → bottom plate, concrete pouring → measurement, pay-off→ base treatment and reinforcement correction→ cushion block placement→, column hoisting → temporary fixation, column correction, → column correction.

Fig.4. Measurement and pad placement

Fig.5. Lifting and falling

Fig.6. The support is fixed

Fourth, technical advantages

The basement of Yungu Jiayuan commercial and residential project adopts SPCS superimposed column components, which makes the project have the following advantages:

Better:

1. Adopt industrial production equipment, high production precision, and can achieve the effect of no plastering;

2. Circular cavity, easy to form, good quality components.

3. Eliminating grouting avoids the problem of temperature influence in the grouting process, and can realize normal construction in winter.

Faster:

1. There is no reinforcement at one end of the component, and the production efficiency of the component is higher;

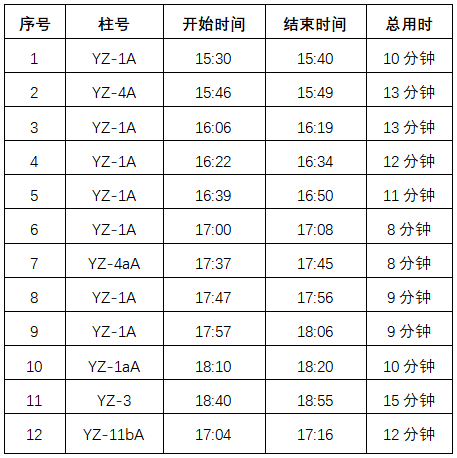

2. Fast installation speed. The cavity has no reinforcement, reduces the interference of the reinforcement, the reserved reinforcement is inserted into the cavity column without obstacles, and the average time for hoisting a column is 11 minutes, and the position is within 30 seconds, which greatly reduces the installation time. The completion time of the installation of the 12 columns is detailed in Table 1;

3. After the component is settled, it is stable, and the hook can be dropped by installing an oblique support, which reduces the occupation time of the tower crane.

Table 1 Statistics of the first installation time of the basement of the Yungu project

Cheaper:

1. The components are simple to install, reducing the labor cost of hoisting workers.

2. The weight of the components is light, and the tonnage of tower cranes or truck cranes needs to be small, which reduces the cost of vertical transportation.

3. The superimposed structure reduces the amount of on-site formwork support and pouring, and reduces the labor cost of carpentry and concrete.

The SPCS superimposed column components used in the basement structure of Yungu Jiayuan commercial and residential project solve a series of problems such as difficult alignment of longitudinal reinforcement, difficult grouting and difficult detection of traditional prefabricated solid column structure, easy to explode mold, poor waterproofing and high cost, and have significant advantages such as easy alignment of longitudinal reinforcement, easy production and higher construction efficiency, which fully embodies the concept of "full prefabrication of walls, columns, beams and slabs, and full assembly of ground and underground" of Sany fully prefabricated building solution, and promotes the industrialization of construction to further move forward in the direction of "better, faster and cheaper".