Blade operation and maintenance technology modification丨What are the solutions to problems such as lightning strikes, freezing, front-edge corrosion, and coating peeling?

2022.10.25

Polaris Wind Power Grid

Since the grid parity, China's wind power blades have entered the extreme of stable development from the stage of capacity expansion, and the blade operation and maintenance technology transformation market has received more and more attention, and it has become an industry consensus to improve the power generation of wind turbines through the operation and maintenance technology transformation of blades.

According to the data, during the "14th Five-Year Plan" period, China's wind turbines below MW level will enter the retirement stage, and the single unit of 1.5MW is below the mainstream model of operation and maintenance technical transformation, and according to the calculation of 30% of the transformation demand, about 10,000 wind turbines will need to be upgraded or retired in the next 5 to 10 years.

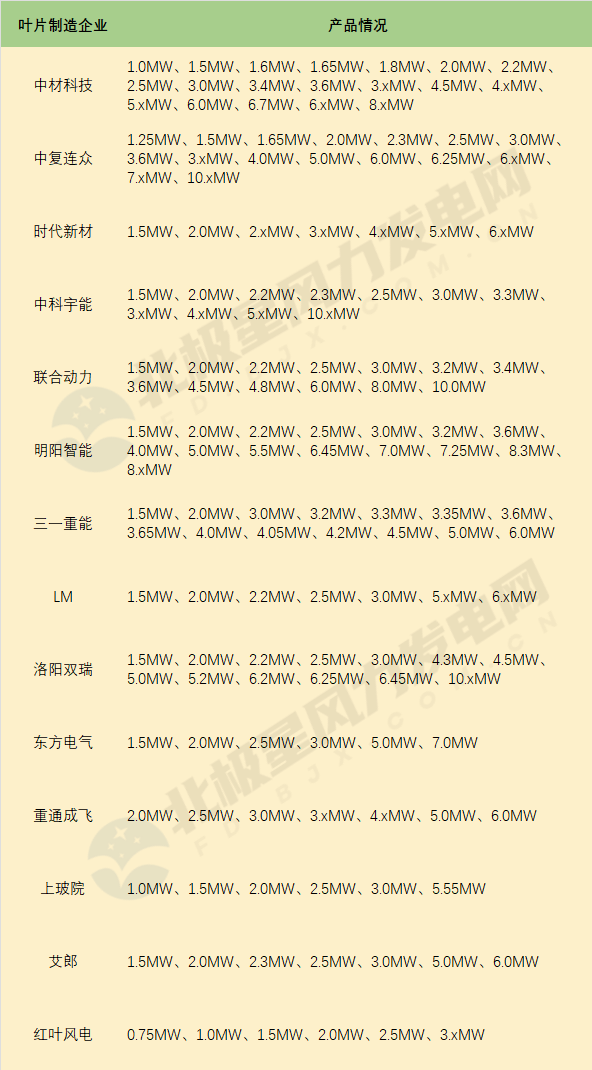

01Blade product series of various manufacturers

In recent two years, the mainstream blade length has been 90 meters and above, and relevant manufacturers have successively launched 101 meters, 103 meters and 110 meters long blades to adapt to large-capacity units.

According to the statistics of Polaris Wind Power Grid, the current product series of each blade enterprise are as follows:

02 Common failures of blades

As one of the most critical components of wind turbines, the after-sales operation and maintenance of blades has the characteristics of long duration, high risk of early operation, difficult on-site quality control, and expensive operation and maintenance costs, resulting in a high threshold for technical transformation of blade operation and maintenance.

Blade defects are generally divided into blade root defects, cavity damage and appearance defects, and the maintenance and repair of blades includes daily operation and maintenance, as well as upgrading and transformation means for various needs and defects.

According to statistics, common wind turbine blade problems include, but are not limited to, lightning strikes, lack of glue on blades, freezing, corrosion of blade fronts, and peeling off of the surface coating of blades.

As far as lightning strikes are concerned, the blade failure loss caused by lightning strikes is generally large, resulting in high maintenance costs, and at worst, the blades are scrapped or cause the unit to catch fire and collapse the tower.

The lack of glue in the blade is mainly caused by poor quality control in the manufacturing and process process, which is very common in the maintenance process, and the situation will lead to the direct breakage of the blade during operation.

Freezing is mainly concentrated in high altitude, northeast and other cold areas, ice falling will endanger the safety of the surrounding environment, but also affect the power generation of the unit,

The problem of coating peeling off is relatively simple to repair, and the peeling area is not large, you can hang up and repair the brush, and the coating falls off in batches or the peeling area is large, and the blades need to be returned to the factory for re-brushing.

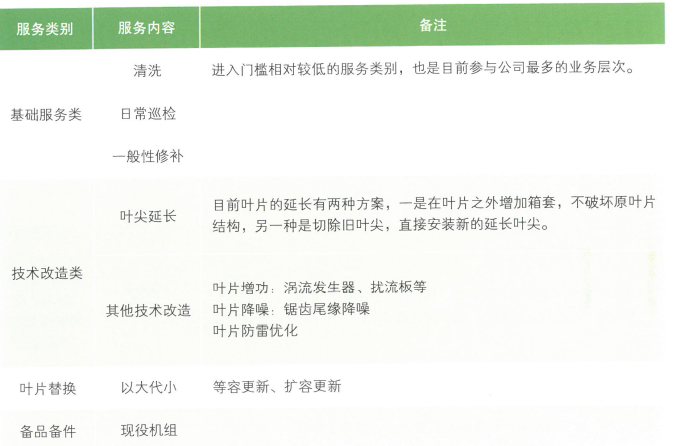

03Blade operation and maintenance technical transformation service content

At present, the operation and maintenance technical transformation of blades is mainly based on basic services, one is the cleaning of blades, daily inspection, and general repair, which has low technical requirements for basic services, relatively low thresholds, and more third-party operation and maintenance enterprises participate.

The second is the transformation and upgrading of blades, including but not limited to blade extension, blade noise reduction, blade lightning protection optimization, blade replacement, etc., which have high technical requirements, and are carried out by the operation and maintenance service team of the whole machine manufacturer and blade manufacturer.

The market potential of wind power operation and maintenance technology transformation is huge, but the operation and maintenance technology and technological innovation of blades are far from being as optimistic as the industry feels, which is one of the reasons why the industry has not formed a competitive enterprise. Especially under the current development trend of early retirement and large pressure on the small, the blade technical correction is facing a relatively embarrassing development situation.

Related testimonials

Start with the Red Sea! Wind power retirement market pains

2025.06.25

CCTV Finance × Sany Heavy Industry: Transportation construction continues to heat up! In May, the infrastructure was full of bright spots →

2025.06.17

CCTV Finance × Sany Heavy Industry: Infrastructure results are released! Anhui is soaring, and the equipment of the western port has become a "dark horse"

2025.05.19

0 comments