Chongqing's first SPCS 3.0 prefabricated building demonstration project landed in Zhongxian County

2021.01.13

Trinity Construction

On January 11, 2021, the official website of the Chongqing Municipal Commission of Housing and Urban-Rural Development issued a notice on the inclusion of Building 1#2# of Hengbang Zhongzhou No. 1 Project in the implementation plan of the city's 2021 Construction Industry Modernization Demonstration Project. The release of this news means:The first in ChongqingThe "SPCS 3.0" prefabricated building demonstration project was officially launched。

Hengbang•Zhongzhou No.1 is located in Zhongxian County, Chongqing, and is a demonstration project for the modernization of Chongqing's construction industry. The project covers an area of 30,358 square meters, with a construction area of 189,424.71 square meters, and a total of 5 residential buildings are planned, of which the above-ground residential parts of the 1# and 2# buildings are adopted“SPCS3.0”Structural systemCarry out prefabricated building design, the total height of the building structure115.5m。

Previously, Chen Miner, secretary of the Chongqing Municipal Party Committee, had particularly emphasized when watching the product display of Sany green building components:The Sany Green Building Project is particularly important, and it is necessary to complete and put the project into operation faster and better。 Now more than half a year, Sany Green Building lives up to expectations and producesSPCS3.0 vertical components will be applied to the 2021 Chongqing Construction Industry Modernization Demonstration Project, taking on the responsibility of leading the development of prefabricated buildings in Chongqing.

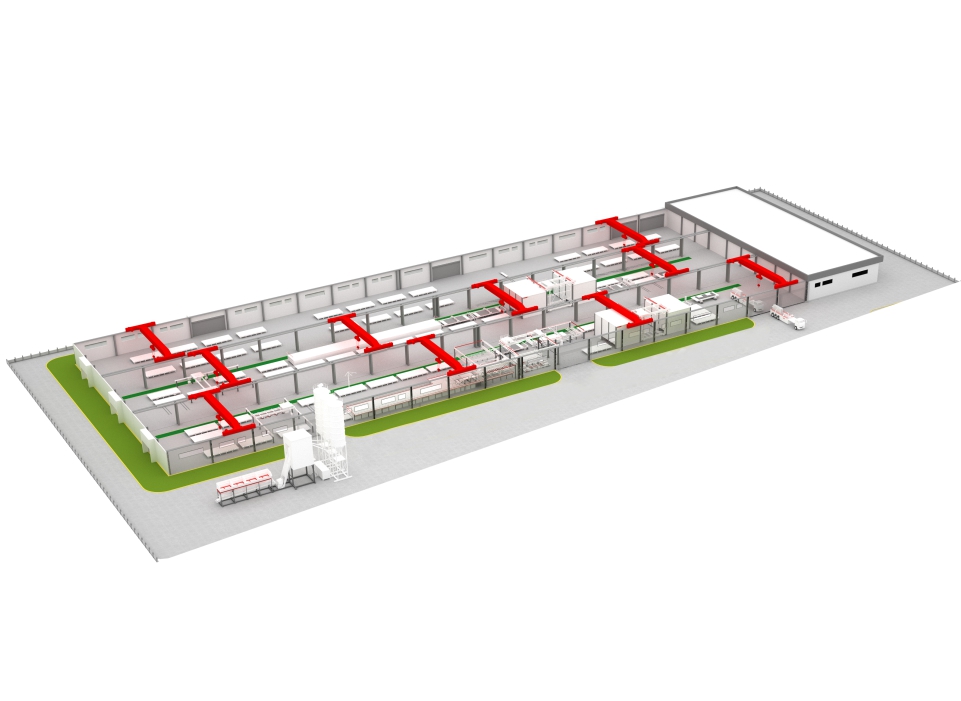

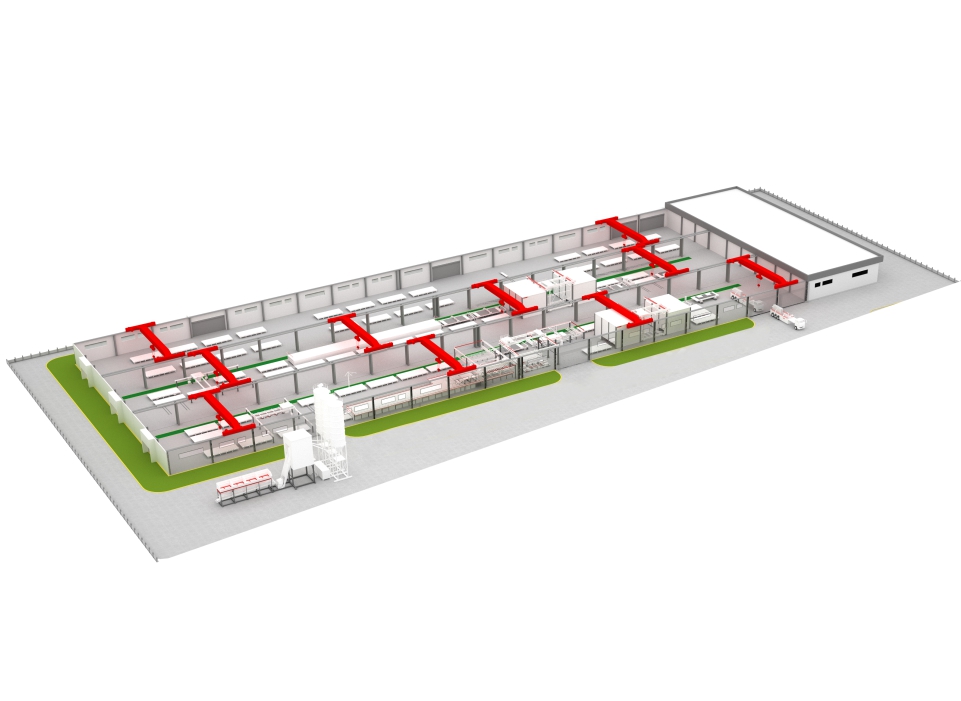

In the production of components, Sany Green Building relies onTrinity ConstructionatThe absolute advantage in PC equipment manufacturing, the Sany comprehensive automated PC production line can provide customers with fully prefabricated PC components including cavity walls, columns, beams and plates.

Sany Construction is a provider of overall solutions for prefabricated buildings, and its equipment manufacturing field can provide complete sets of intelligent equipment and industrial software for prefabricated buildings. Among them, TrinityThe degree of informatization of PC integrated automatic production line has reached the leading level, and for the first time in China, a high degree of integration of PC production line, PC mixing station and steel bar equipment has been realized, and automatic matching has been realized, so as to truly realize digital-driven production.

SPCI-PMESsystemAsThe control center of digitally driven and automated production of PC parts can realize intelligent collaborative BIM 3D models and 4D plans, helping PC factories to achieve less manpower and flexible JIT production and delivery, and has the following six advantages:

Digital Drive Intelligence:The system opens up the automatic analysis channel of the component model output by the mainstream component design software at home and abroad, which can be docked and extractedPKPM, PlanBar, CAD and other design models, reorganize the production process data-driven equipment operation, and eliminate the need for secondary mold turning, manual measuring tape and manual processing of component drawings.

Fewer people are efficient:Direct drive designPC production line intelligent production, the number of workers in the whole line can be about 60% less than the traditional one, and the key processes such as formwork, steel bar processing, reinforcement, cloth, and stacking are automated, and the production cycle is 15min.

Collaborative scheduling:The system systematically plans production scheduling, automatically assembles molds, forms production tasks with the mold table as a unit, and systematically schedules resources such as steel bars, concrete, accessories, and production workers to achieve balanceJIT production, the utilization rate of the mold table and the production capacity have been greatly improved.

Touchscreen Visualization:Full touch screen, mobile human-computer interaction design, high degree of automation, simple and convenient operation.

Online Services:8h automatic online commissioning, quality inspection and delivery, customers can check the operation status of the equipment on the SPCI applet at any time, and realize one-click service call, and the troubleshooting service is online, transparent and efficient.

Predictive Adaptive:Touch screen, applet, central controlThe MES side pushes equipment early warning and maintenance, beat timeout reminder and processing, temperature and humidity curing, and vibration process parameters are adaptively adjusted according to the concrete and mold table tasks to ensure the production quality of components.

Sany PC integrated automated production line

SPCE smart PC equipmentRecommended products

PC production line

Sany PC integrated automated production lineRelated testimonials

CCTV Finance × Sany Heavy Industry: Transportation construction continues to heat up! In May, the infrastructure was full of bright spots →

2025.06.17

CCTV Finance × Sany Heavy Industry: Infrastructure results are released! Anhui is soaring, and the equipment of the western port has become a "dark horse"

2025.05.19

China's installed wind and solar capacity has historically surpassed that of thermal power

2025.04.28

0 comments