Contribute to the development of intelligent oilfields

2021.10.27

Carbon customer Lakb

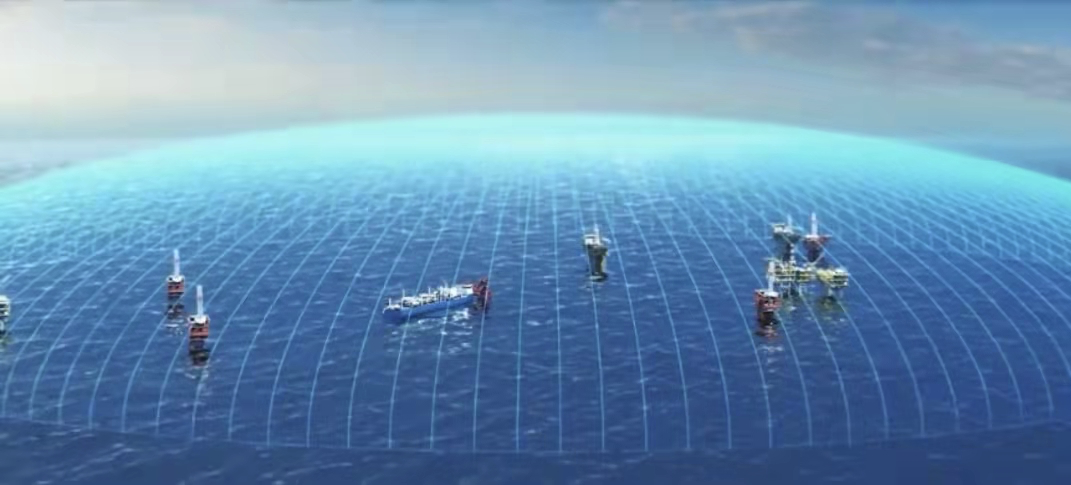

In the future, offshore platforms will gradually realize automation, integration and collaboration of production and operation, and standardization and sharing of exploration and development data resources. With the deepening of the understanding of intelligent oilfields and the gradual acceleration of the pace of practice, more intelligent, safe and environmentally friendly offshore oilfields are beckoning to us.

Internet of Things, Big Data, Cloud Computing, Artificial Intelligence……In today's world, information technology innovation is changing with each passing day.It has had a huge impact on the development of all walks of life.This of course also includes the energy industry.

Recently, China's first offshore intelligent oilfield,Qinhuangdao 32-6 Intelligent Oilfield (Phase I),Fully completed and put into use,Applying cloud computing, big data, Internet of Things, artificial intelligence, 5G and other information technologies,Empowering offshore oilfields,intelligent oilfield,It has become an important way for oil companies to reduce costs and increase efficiency, save energy and reduce consumption, and environmental protection in oil and gas production. Digital oilfield is a fully informationized oilfield virtual body, which realizes the digitalization, networking, intelligence and visualization of the oilfield.

With the help of business models and expert systems, the intelligent oilfield is an upgraded version of the digital oilfield, which realizes comprehensive perception of oil and gas field dynamics, automatic control of activities, and prediction of change trends, and then continuously optimizes decision-making and management, improves new reserves, production, and recovery factors, ensures safe production, and helps low-carbon environmental protection.

For exampleOn October 14, 2018, the Oseberg-H oilfield in Norway was put into production, and it was remotely operated by the Oseberg Oilfield Center.No regular inspections are required, and maintenance is only carried out 1-2 times a year, and the oilfield is designed and built using new digital technology.The delivery price is $795 million, which is 20% lower than the Development Operations Plan (PDO) cost and the cost of a barrel of oil is as low as $20/bbl.

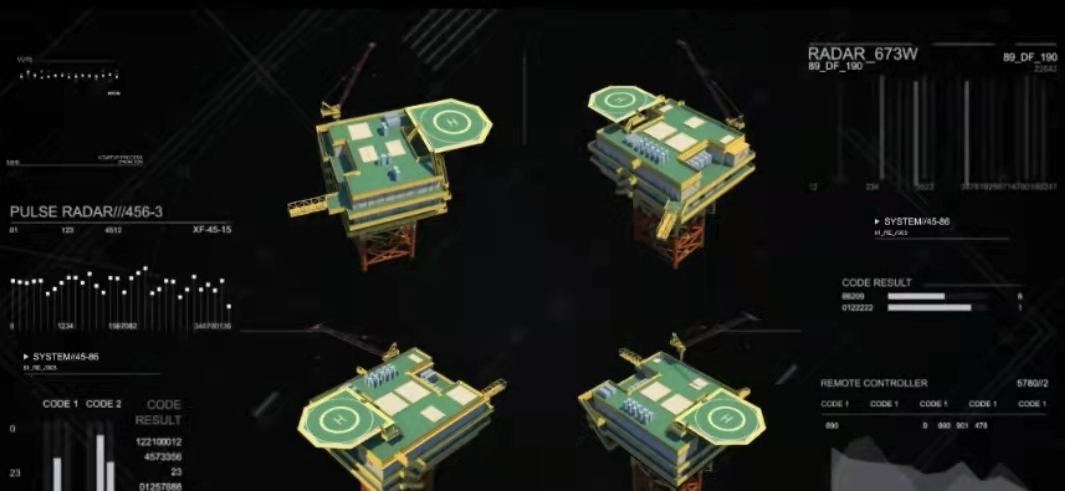

How does a smart oilfield have these features? One isreal-time perception,It is necessary to obtain production data and video in real time 24 hours a day by equipping intelligent instrument equipment, always sensing the respiratory pulse of the oilfield, and mastering the quantitative vital signs.Comprehensive collaboration, through the integration of visual technology applications, to achieve cross-professional remote collaboration in various fields, the organization of "expert consultation", to solve oilfield health problems, improve oilfield physical function. The second isactive management,Through business and technical modeling, the oilfield is equipped with a "smart brain", timely warning, prediction and recommendation of accident solutions, change post-processing to pre-control, overall optimization, integration of reservoir, wellbore, and surface models, establish an integrated asset model, realize the overall optimization of all assets, and improve the quality of decision-making.

In what aspects of the intelligent oilfield, the "version upgrade" has been realized, first of all,Intelligent technology helps oil and gas fields,Reduce costs, improve quality and efficiency, and intelligent monitoring and inspection can reduce the cost of manual operation, improve the reliability of equipment, and extend the life of equipment.For example,The construction of Qinhuangdao 32-6 intelligent oilfield will bring 30% increase in production efficiency, and is expected to bring direct benefits of more than 30 million yuan per year, and the investment can be recovered within 6 years, and long-term sustainable benefits will be obtained. BesidesIntelligent oilfields can also quickly identify the risks and hidden dangers of personnel and equipment, improve the efficiency of accident response, and help energy conservation, emission reduction and environmental protection through real-time energy consumption monitoring and dynamic analysis and optimization, for example, Qinhuangdao, 32-6 intelligent oilfield, using AI artificial intelligence recognition technology, comprehensively perceive the unsafe behavior of people, the unsafe state of things, and the loopholes of management in the process of operation, so as to realize the organic combination of "people + technology + management".In addition, the intelligent oilfield will also change, with multiple levels of decision-making, problems being reported layer by layer, and instructions being issued layer by layerThe traditional decision-making mode realizes intelligent and efficient management, after the completion of Qinhuangdao 32-6 intelligent oilfield.Different positions can obtain first-hand information at the same time, eliminate business barriers, unite data silos, achieve professional collaboration and data integration, and make the decision-making process more efficient and the decision-making results more scientific. The application of intelligent technology can also play a very important role in the application of intelligent technology in the "Shenhai No. 1" energy station, the integrated dynamic digital twin system realizes the real-time simulation of the whole production process, and effectively solves the problem of deepwater flow safety. At lastThe construction of intelligent oilfields will be based on the optimization and reorganization of personnel, and the establishment of a production control center as the core.

Sany Petroleum has built an equipment interconnection model, with the ability of equipment interconnection and data exchange, and its four major application scenarios include aftermarket services, energy consumption management, equipment asset management, and financial leasing. In this way, it can realize a series of industrial capabilities in the digital era, such as equipment life cycle management, digital design and development, digital production and manufacturing, and predictable after-sales and maintenance services, and help the oilfield change to an intelligent development model.

Rail-mounted container gantry crane automation

Rail-mounted container gantry craneRecommended products

automation

Rail-mounted container gantry crane automationRelated testimonials

CCTV Finance × Sany Heavy Industry: Transportation construction continues to heat up! In May, the infrastructure was full of bright spots →

2025.06.17

CCTV Finance × Sany Heavy Industry: Infrastructure results are released! Anhui is soaring, and the equipment of the western port has become a "dark horse"

2025.05.19

China's installed wind and solar capacity has historically surpassed that of thermal power

2025.04.28

0 comments