Sany Heavy Industry Sany Heavy Industry Co., Ltd. (SH:600031)

Trinity International Sany International (HK:00631)

Sany Renewable Energy Sany Renewable Energy (SH:688349)

Fresh factory exploration! Sany Changsha New Park is coming

2021.11.02

Sankei Weekly

Recently, according to the news of the project party of Sany Zhilian heavy truck and construction machinery expansion project block B, the main construction project of the two plants in plot B has been completed, and the welding workshop of the heavy truck joint plant will be put into operation at the end of the year, and other plants and workshops will be put into use at the end of next year. In this regard, a reporter from Changsha Evening News drove to the project site to learn more about the construction of the plant. Su Zhan, the project manager, said: "After completion, it will be one of the largest and highest manufacturing plants in Sany. ”

At the project site, more than 100 welding robots and some coating manipulators have entered the site for installation and commissioning, and there are more than 300 on-site technicians. Photo by Huang Qiqing

With curiosity about the project, the reporter followed Su Zhan into the project site. After walking down and chatting for more than an hour, "large area, fast speed and intelligence" are the three most intuitive impressions of the reporter's construction of two production plants, the Deutz engine plant and the heavy truck joint plant in plot B.

Large areaOne factory is the size of nearly 30 football fields

Entering the construction site from the south entrance and exit of the project, driving around the outer wall of the factory for a few minutes, an open road is impressively ahead.

To the north of the road is the 120,000-square-meter Deutz engine plant, the main construction of which has been completed, and the glass curtain wall has been installed to the top. In the empty workshop, the equipment has not yet been installed on site, and there are few construction personnel on site.

To the south of the road, is a heavy truck joint plant, the longest depth of 589 meters, the widest depth of 388 meters, a single plant construction area of 240,000 square meters, equivalent to the size of nearly 30 football fields, according to the number of normal steps, from the north end to the south end, it takes nearly 10 minutes.

Entering the heavy truck joint plant from the gate, you will see an exhibition hall with hundreds of square meters in size, and several workers are standing on the aerial work platform to do the final sweeping work. "LaterSany heavy truckThe assembly process, parts, and heavy-duty truck models will be displayed here. Su Zhan introduced.

Natural light comes in overhead, which can greatly reduce the lighting of the plant

The use of equipment is more green and environmentally friendly. Photo by Huang Qiqing

Passing through the exhibition hall, the light in the factory suddenly brightened, and a glass lighting roof ran through the north and south.

Under the skylight, fountains, palm trees, and plantain trees exude a tropical atmosphere. More than a dozen workers bowed their bodies and planted pots of birds of paradise, flowering and leafy green trees, and Jiangnan star ferns in the soil, with different colors and patchwork. Behind it is a lawn hundreds of meters long and more than ten meters wide, green and lush, like a tropical garden.

Those who have visited Sany may feel familiar with this plant, because most of the Sany plants, represented by No. 18 plant, abide by the same green design concept.

It's fast

The main project of 400,000 square meters was completed in less than a year

In July last year, when the earthwork construction of plot B of the Sany Zhilian heavy truck and construction machinery expansion project began, Su Zhan was stationed at the site to be responsible for the construction of the entire project.

"The construction of the main project of 400,000 square meters was officially started in early October last year, and it was officially completed on September 28 this year, less than a year before and after." Su Zhan said that plot B is a typical demonstration project of Sany's digital transformation, and the two factories are built in accordance with the standards of "lighthouse factory", and many details are integrated into the concept of "green factory".

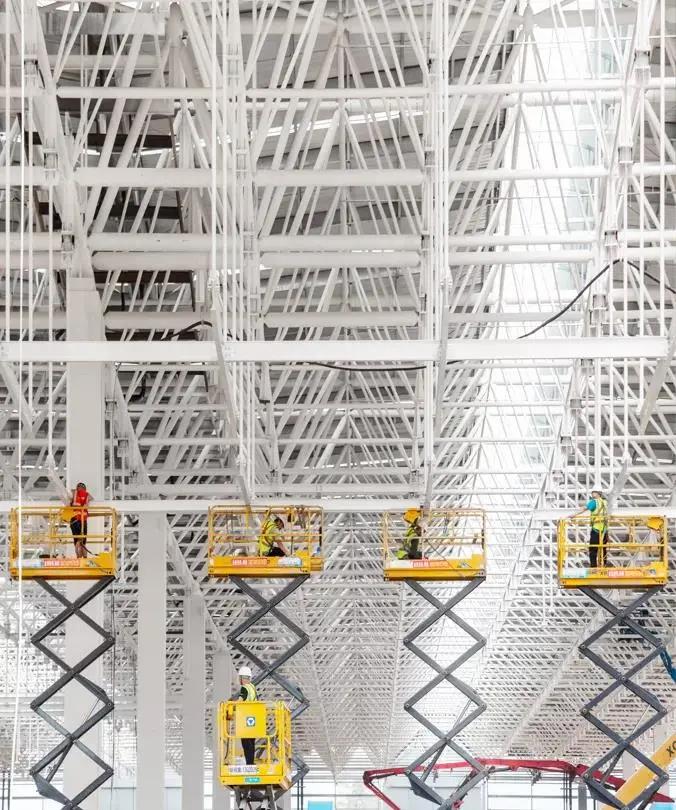

The reporter learned that in the past year, the largest construction task of the project on plot B is the installation of steel structure columns and top grid structure, and at the busiest time, there are more than 2,000 on-site construction personnel.

Looking up, the steel pipes with the thickness of an arm are "hand in hand" and are "weaved" into geometry

The graphic, like a net-like steel forest, supports the roofs of the factory buildings.

Photo by Yi Xiaohua

"The entire production plant of plot B adopts the principle of project segmented delivery and time-sharing entry of equipment, and a section is delivered when a section is built to speed up delivery efficiency." Su Zhan told reporters that since July, some equipment in the welding workshop, cab painting workshop and vehicle assembly workshop have been installed and debugged.

Intelligent

Hundreds of welding robots entered the site for commissioning

The reporter saw from the layout of plot B that although the "Big Mac" general heavy truck joint plant is huge and open, it is actually composed of multiple workshops such as stamping workshop, vehicle assembly workshop, welding workshop, cab assembly workshop, and cab painting workshop.

The welding workshop is the largest workshop in the heavy truck joint plant, covering an area of more than 50,000 square meters, and it is also the most interesting workshop at present. "At present, more than 100 welding robots and some coating manipulators have entered the site for installation and commissioning, and there are more than 300 on-site technicians, and the commissioning will be completed at the end of November." Su Zhan introduced.

Photo by Huang Qiqing

The reporter saw that the orange-red welding robots were either alone or in groups, with an island-like layout, and a protective wall more than one person high was built with glass around the perimeter. The huge robotic arm is controlled by a technician to flexibly change the welding angle.

Xia Gong, an electrical engineer from Anhui, has been working in the plant for a month and a half. He told reporters that only their team, there are more than 40 technicians, the recent workshop to rush the construction progress, basically every day will work overtime until 9 o'clock in the evening, "the electrical engineering of the entire plant is fully commissioned, is expected to wait until April and May next year." ”

In the welding workshop, a hanger and pedestrian passage in mid-air have also been installed, and people and heavy trucks have "diverged lanes". At that time, a piece of steel plate will be "walking in the air" through the hanger, arriving at the welding workshop, under the skillful hands of a robot "welder", welded into a heavy truck cab, and finally assembled into a "warm home" for cardholders on the highway.

Next article:The per capita output value is 10 million! The secret of Trinity's "Lighthouse Factory".

0 comments

Related testimonials

"Science and Technology Daily" Focus! Sany 6 minutes "intelligently made" an electric heavy truck

2025.04.25

From the hardcore breakthrough of steel power to the emerging revolution of a zero-carbon future, Sany Heavy Truck is moving towards the new

2025.03.13

The resumption of work and production accelerated, and the sprint made a good start

2025.02.24

0 comments