Sany Heavy Industry Sany Heavy Industry Co., Ltd. (SH:600031)

Trinity International Sany International (HK:00631)

Sany Renewable Energy Sany Renewable Energy (SH:688349)

Home > Media coverage > The per capita output value is 10 million! The secret of Trinity's "Lighthouse Factory".

The per capita output value is 10 million! The secret of Trinity's "Lighthouse Factory".

2021.11.04

Brocade public account

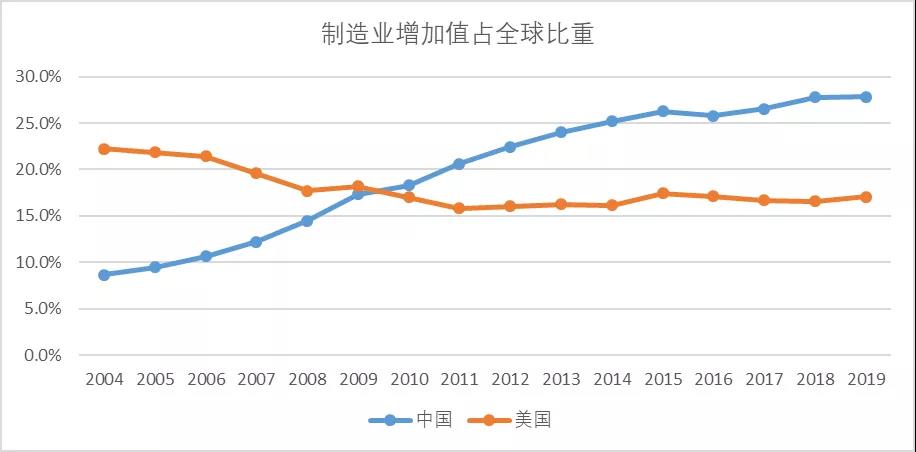

In the past 20 years, China's manufacturing industry has solved the problem from small to large. Standing in the context of the new normal of the economy, in the next 20 years, the problem that China's manufacturing industry urgently needs to solve has become how to grow from big to strong.

Figure 1: The rapid rise of China's manufacturing sector, Source: World Bank

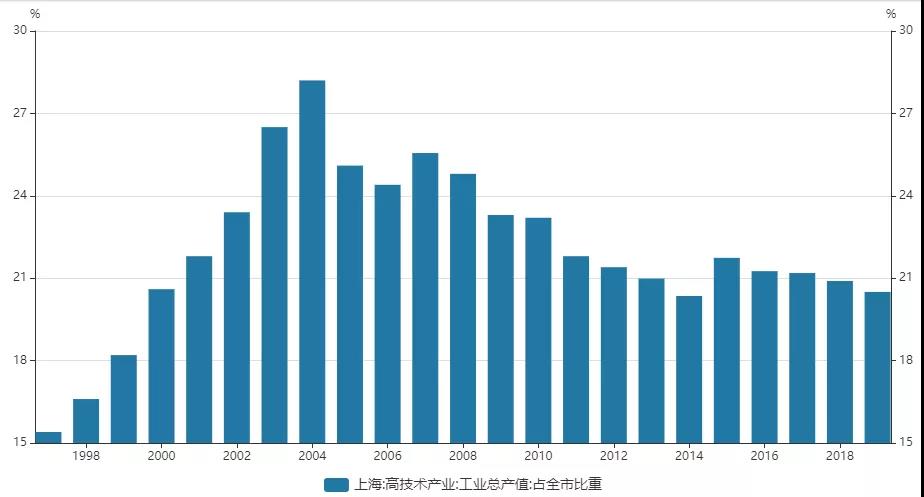

Figure 2: The trend of domestic manufacturing industry upgrading is not obvious, source: Shanghai Municipal Bureau of Statistics

With the historic transformation of economic development goals from fast to excellent, transformation and upgrading have become the new core of the manufacturing industry.

The academic community has concluded that from the perspective of the law of the evolution process of the growth momentum of the manufacturing industry, the manufacturing industry will first develop labor-intensive industries (such as textiles and garments) through the labor dividend, and then increase capital investment to develop capital-intensive industries (such as shipbuilding), and finally need to enter the progress of technology to drive the manufacturing industry into technology-intensive (such as robots).

It can be seen that the direction of China's manufacturing transformation is very certain, that is, Industry 4.0. Only in this way can China's manufacturing industry break through the bottom of the smile curve and move towards high added value.

There are always pioneers in icebreakers. On September 27 this year, the World Economic Forum (WEF) officially released a new list of "lighthouse factories" in the global manufacturing field, and Sany Heavy Industry (SH: 600031) Beijing Pile Driver Factory was successfully selected, becoming the first certified "lighthouse factory" in the global heavy industry industry.

Why Sany Heavy Industry? How can its sample meaning be replicated?

Figure 3: Four stages of industrial development, source: German Research Center for Artificial Intelligence

01The pioneer of manufacturing transformation and upgrading: Sany Group

[1] Made in China business card

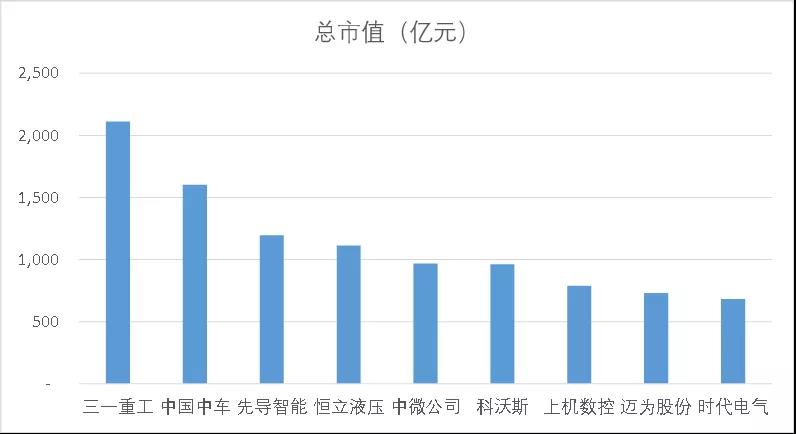

Sany Group was founded in 1989, and its development stage coincided with the two major cycles of domestic labor dividend and later capital expansion. Sany has also taken advantage of the two tides to achieve rapid development and become the first in China and the top three in the world. Taking Sany Heavy Industry, the largest listed company under Sany Group, as an example, its market value has reached 210 billion yuan, becoming the largest company in the domestic machinery and equipment industry and the only company in the same industry with a market value of more than 200 billion yuan.

Not only is it the largest in terms of market capitalization, but in terms of brand awareness, Sany has also become a company that can represent the image of China's manufacturing industry. In May this year, American star Kim Kardashian bought an excavator from Sany Heavy Industry to give to her child, you know, the world's largest construction machinery company is an American company, called Caterpillar, and Kim Kardashian finally chose Sany Heavy Industry.

Figure 4: Market capitalization ranking of A-share listed companies in China's machinery industry, as of October 25, 2021, source: Wind

[2] Sany's business layout requires it to accelerate the pace of transformation

In addition to the largest market capitalization, Sany Heavy Industry is also one of the enterprises with the highest comprehensive layout.

The company has a wide range of products, including excavators, concrete machinery, lifting machinery, road construction machinery,Piling machinery, wind power equipment, heavy trucks, port machinery, petroleum equipment, coal equipment, environmental protection equipment, etc., basically involve each subdivision of construction machinery.

What is more noteworthy is that among the manufacturing companies, Sany is one of the first Chinese companies to go global. According to the data of Sany Heavy Industry, one of its listed platforms, overseas revenue has already exceeded 10 billion, and the proportion of revenue is close to 4% at the highest time. It can be said that Sany is also one of the enterprises most suitable for the Belt and Road Initiative.

Just like the front and back of the coin, multi-category production and global layout, Sany Group, as the business card of China's manufacturing industry, is facing the greatest pressure for transformation.

Figure 5: Sany is the first representative enterprise to go overseas (taking the financial data of Sany Heavy Industry as an example), source: the company's financial report

[3] It has already been acted: either turn over or capsize

As a Fortune 500 company with 36,000 employees, Sany did not lie on the merits, but retained the sense of distress in the early days of entrepreneurship. As early as a few years ago, Sany saw the necessity and urgency of upgrading manufacturing enterprises under economic transformation.

For the outside world, the earliest insight into Sany's transformation was in March 2018, when Mr. Liang Wengen, chairman of Sany Group, said at the 13th National People's Congress that Sany's digital transformation would either turn over or overturn.

said so harshly, this is not just a matter of taking precautions, but even showing the determination to live to die.

Later, here is the story we saw, and one landmark event after another began to appear:

In October 2018, Sany Intelligent Research Institute was established, which jointly promoted the digital transformation of the company with the Intelligent Manufacturing Headquarters and the Process Informatization Headquarters. It consists of Intelligent Manufacturing Research Institute, Industrial Intelligence Research Institute, Sany Robot, Shengjing Technology, etc., which are responsible for the development, pilot, planning and implementation of 4IR technology.

In 2019, Sany Group started manufacturing upgrades, and the first batch of 6 smart factories, including Changsha No. 18 Factory and Beijing Pile Driver Factory, began to be renovated, becoming the largest factory renovation project in China.

…….

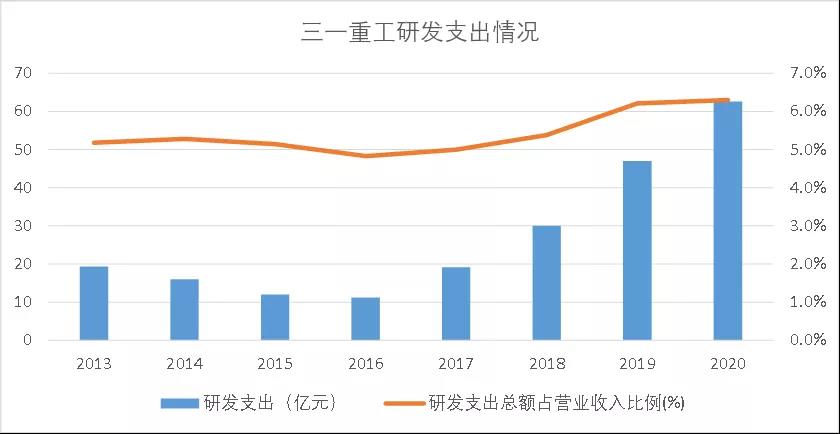

From 2018, the company's R&D expenditure has gradually increased from 5% to 6.3%, and the absolute amount has also rapidly increased to 3 billion yuan, and then to 6 billion yuan. You must know that in 2018, construction machinery has just recovered into a new cycle, and the net profit of Sany Heavy Industry at that time was only 6 billion yuan.

Figure 6: Sany's R&D expenditure has risen rapidly since 2018 (taking Sany's financial data as an example), source: the company's financial report

After a few years, Sany has become a pioneer in transformation.

In terms of horizontal comparison:

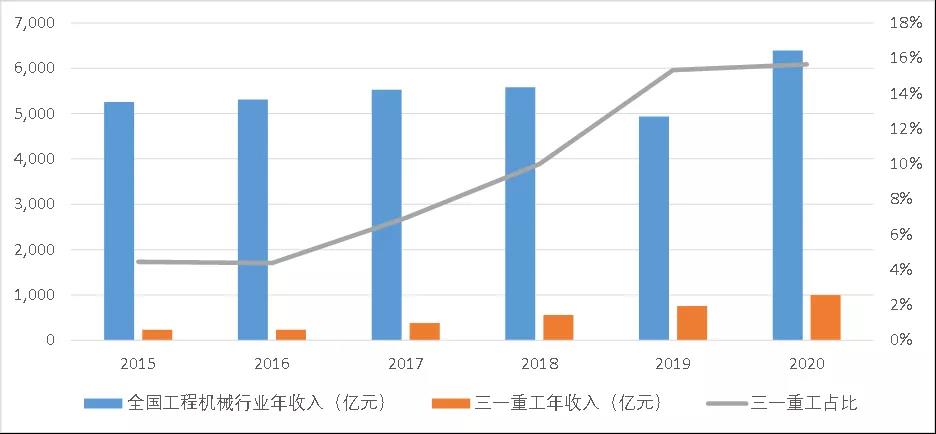

The construction machinery industry is a huge industry, in China, the number of construction machinery industry enterprises as high as about 1,500, the average annual sales of only 4-500 million yuan. In terms of volume, Sany is an absolute leading enterprise, in 2020, Sany Heavy Industry, a subsidiary of Sany Group, will have an income of 100 billion yuan, accounting for 16% of the entire construction machinery industry (if it is Sany Group as a whole, this proportion will further rise to 21%).

Therefore, the transformation of Sany is the turn of the elephant in the construction machinery industry. From 2015 to 2020, Sany Heavy Industry's revenue rose rapidly from 23.4 billion yuan to 100 billion yuan, while the industry basically maintained a scale of 5000-600 billion yuan.

Figure 7: Sany Heavy Industry is the largest construction machinery enterprise in China, source: National Bureau of Statistics, Sany Heavy Industry Company's financial report

Longitudinal analysis:

Not only in China, but also in the world, it is unique for such a large manufacturing enterprise to carry out all-round digital transformation.

Under the leadership of Chairman Liang, Sany has set specific goals for its digital transformation strategy, which are internally known as Sansan goals: 300 billion sales, 3,000 workers, and 30,000 engineers.

The ambition behind the numbers is on paper, with sales of 300 billion yuan, which is more than 1 times the sales of Sany Group of 136.8 billion yuan in 2020, that is, "rebuilding another Sany". How to recreate a Trinity is not a simple logic of expanding the scale. Why do you say that, the per capita output value implied by the 33 goal is 10 million yuan, which is more than double that of the current company; This means that Sany needs to innovate the organization and the industrial chain, which is also reflected in the fact that the number of engineers and employees will be 10 times the number of manufacturing workers in the future.

In essence, Sany aims to become a pioneer in intelligent manufacturing, and the driving force for development will switch from labor dividends to engineer dividends, resonating with the times. Today, Sany's digital transformation has achieved fruitful results, and it has taken the lead in entering the digital no-man's land, and with the implementation of the Sansan goal, Sany will also be the first to cross the no-man's land in the future.

Figure 8: Sany Group's digital transformation goals, source: company information

02Pioneer: Walk into Sany Beijing Pile Driver Factory

shouted the slogan of living to death, and also invested real money, what is the effect of Sany Group's transformation and upgrading? We decided to go down into the production floor to find out.

As one of the first batch of factories to carry out intelligent and digital transformation, Beijing Pile Driver Factory is the epitome of Sany's phased achievements in intelligent transformation.

[1] Beijing pile driver factory before the transformation

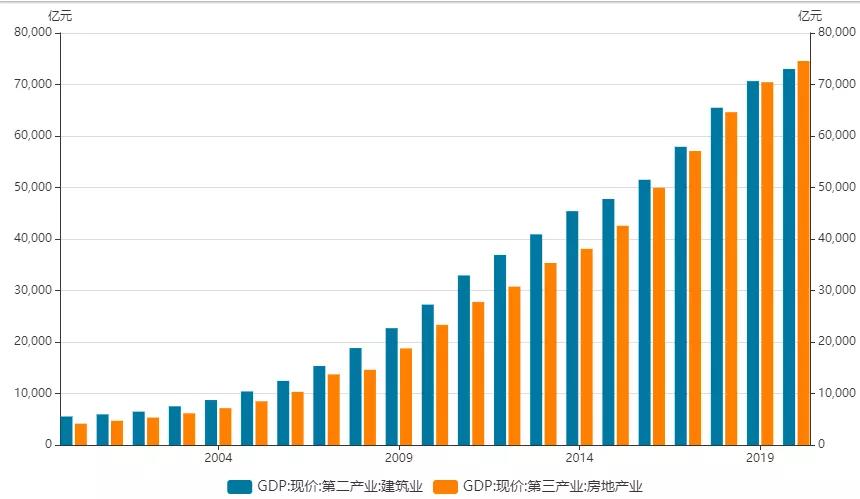

Pile driver, is the abbreviation of pile machinery, refers to the machinery used for drilling, piling and sinking piles in various pile foundation construction, and is the basic equipment for urban housing construction and infrastructure construction. From the perspective of China's GDP composition, the total annual added value of the construction industry and the real estate industry is about 15 trillion yuan, accounting for 15% of GDP, and the construction real estate industry chain is long, which is also the cornerstone of other industries; It is precisely because of this that the piling machinery, as a necessary infrastructure construction, is an out-and-out heavy weapon of a great country.

Looking forward to the future, the domestic economic development emphasizes more quality, such as the pursuit of digital construction, advocating low energy consumption, encouraging new energy, etc., the infrastructure industry has also entered the era of "new infrastructure", the importance of piling machinery has not decreased but risen, and entered the "tower era". We have seen that at the site of new infrastructure construction such as wind power, 5G base stations, and IDCs, large towers have occupied the mainstream. It can be said that the speed of the new piling machinery has injected the growth momentum of corner overtaking into this round of new infrastructure construction of a large country.

Figure 9: Construction and real estate are the cornerstones of China's economy, source: National Bureau of Statistics

The production mode of piling machinery is a typical discrete manufacturing, with many varieties, small batches, complex processes, and many pain points that are difficult to solve.

But what you generally don't know is that there are many parts and components of the pile driver, including 17 modules from bottom to top, including walking mechanism, onboarding, triangle, auxiliary winch, mast cylinder, guide wheel carriage, middle mast, turbine frame, drill bucket, main winch, lower mast, power head, pressurized cylinder, drill pipe, follower frame, lifter, upper mast, etc.

Therefore, the manufacturing of pile driver is a typical discrete production mode, and the traditional manufacturing method needs to be equipped with a large number of equipment, a large area of site and a large number of labor, which is a representative industry of capital and labor intensity.

Figure 10: Schematic diagram of the pile driver, source: company information

The double intensity of capital and labor is very prominent in Sany pile machine factory.

Sany's Beijing Pile Driver Factory was completed in 2011 and plans to produce 50 rotary drilling rigs per month, making it one of the largest pile driver factories in China. Relying on this, Sany has grown into a leading global pile driver company, with the largest market share in China and the world; And the per capita income of the pile driver factory is close to 5 million yuan, which is the leader in China.

As of 2018, before the transformation, the annual output was 1,256 units, but the output of more than 1,000 units required the number of workers reached about 2,000. This is because in terms of product types, there are 10 main models of Beijing pile driver products, and the 10 key components are self-produced, resulting in fragmentation of the production model.

It is precisely because of the early construction, the discrete production process (many parts, self-produced, and many models), and the annual sales of about 5 billion yuan of Sany Beijing Pile Driver Factory, in terms of automation and intelligence, will only pass.

[2] Beijing pile driver factory after the transformation

As the first shot of intelligent transformation, Sany put forward a very high goal for the intelligent transformation of Beijing Pile Driver Factory:

1) In 2019, the overall level of intelligent manufacturing of pile drivers in Beijing reached the industry 4.0 standard.

2) In 2020, it will reach the highest level of national intelligent manufacturing level 5 (leading level "Guidelines for the Construction of National Intelligent Manufacturing Standard System (2018 Edition)"), and achieve the World Economic Forum lighthouse factory certification.

It is necessary to explain the meaning of the Lighthouse Factory, which is a demonstration of digital manufacturing and Industry 4.0 selected by the World Economic Forum (WEF) and McKinsey & Company since 2018, and the factories that have obtained this certification are basically recognized as having world-class manufacturing capabilities.

Figure 11: Lighthouse Factory, Source: Network

In 2018, it put forward the goal of representing the highest level in the industry, and the intelligent transformation of Sany Pile Crane Factory can be described as a tight time and heavy task. After more than two years of intense transformation, what is the final result?

According to the latest data, the Beijing pile driver factory has reached the industry 4.0 standard, and achieved the certification of the lighthouse factory, successfully completed the set goal, and this is also the first "lighthouse factory" in the global heavy industry industry, ahead of the global leader Caterpillar in the industry, adding a strong stroke to the world's leading Chinese manufacturing.

In addition to obtaining international certifications, the most intuitive results of intelligent transformation are reflected in the per capita output value. After the transformation, the monthly production capacity of the pile driver factory has doubled, and the overall sales volume will reach 7.7 billion yuan in 2020, and what is even more amazing is that the per capita output value has increased to 10.72 million yuan.

In order to intuitively understand what the concept of 10 million yuan is, we select the top 20 enterprises in the per capita output value of the same construction machinery industry, the per capita output value of these 20 enterprises is only 1.9 million yuan, and the pile driver factory after the transformation is more than 4 times the average level; Even compared with Sany Heavy Industry itself, it has doubled. People's Daily Online therefore calls this the "lighthouse effect". As an aside, from the average output value of the industry, we can also feel the urgency of the task of upgrading and transforming China's manufacturing industry.

[3] The secret behind the per capita output value of tens of millions

Through the above comparison, we can see the huge changes in the Beijing pile driver factory before and after the transformation, and this was completed in less than 3 years, which seems to give people an illusion that it is not difficult to upgrade.

In fact, how to automate and intelligentize the discrete production process is a worldwide problem of Industry 4.0, so there are no world-class giants in this field.

At present, it is widely recognized in the industry that the industrial Internet is used as a transformation tool. By definition, the industrial Internet is a carrier that builds a service system based on massive data collection, aggregation and analysis for the digital, networked and intelligent needs of industrial enterprises, supports the ubiquitous connection, flexible supply and efficient allocation of manufacturing resources, improves the level of automation and informatization for industrial users, and finally realizes the vision of "making industry full of wisdom and letting wisdom create value".

Figure 12: Schematic diagram of the industrial Internet platform architecture, source: Juchao Information

According to this overall guiding goal, relying on the "root cloud platform" of tree root interconnection, Sany Heavy Industry Beijing Pile Driver Plant has started the digital transformation and upgrading, and the specific plan covers the whole stack, including the equipment layer, the control layer, the operation layer, the factory layer, and the enterprise layer:

The equipment layer and the control layer are composed of automated production lines/equipment and warehousing logistics, and the most important thing is to realize the automation of the operation terminal and logistics system hardware.

The operation layer mainly realizes data collection and equipment interconnection, which is the cornerstone of realizing the digitalization of the entire factory and finally completing the digital twin of the production process.

The factory layer covers the operation management MOM system, which is mainly composed of APS, MES and other systems to improve the intelligent level of the production process in the early, middle and late production stages.

The enterprise layer is the operation and management of the enterprise, which is mainly composed of ERP, PLM, SCM and other systems, which connects the inside and outside of the factory to improve operational efficiency.

To get a glimpse of the effectiveness of a full-stack solution, we can look at it from an automation and digitalization perspective. It's easy to understand that only by automating can labor density be significantly reduced; Only by realizing digitalization can intelligence be unleashed, and finally realize material saving, efficient production, and achieve a density that reduces capital intensity. Eventually, labor-intensive and capital-intensive industries will be upgraded to technology-intensive industries.

Based on the interview records of Dr. Huang Pei, an expert in intelligent manufacturing, and Dai Qinghua, director and senior vice president of Sany Group, we have extracted important details that reflect its automation and digitalization:

Automation: When the Beijing pile driver factory was completed, the annual output of the planned rotary drilling was about 500 units, and 2,000 workers were needed to complete the manufacturing process, and the number of workers was reduced to 500 after the completion of the construction of the lighthouse factory, but the output rose to 3,000 rotary drilling rigs, which relied on replacing people with a large number of machines, and the manufacturing efficiency was greatly improved. There are more than 170 robots in the renovated factory, including handling robots, bevel robots, truss robots, AGVs and so on.

Digitalization: In order to digitize the factory, we have connected all devices to the Internet through 5G technology, and there are now more than 430 devices connected to the network. On the first layer, after networking, we can monitor the start-up rate and operation rate of all equipment in real time. The deeper layer is the implementation of the digital twin, after the deep digitization of the factory, we create a digital twin of the factory, and then build the physical factory based on the twin, which greatly shortens the delivery cycle and can also achieve efficient operation.

In order to further deepen our understanding, we take the specific small link of logistics and warehousing as an example, through the construction of intelligent three-dimensional warehouses for raw materials, intelligent three-dimensional warehouses for outsourcing and outsourcing, and the use of frame manipulators/AGV loading and unloading materials, AGV/RGV distribution materials, and WMS to manage inventory logistics, so that logistics and warehousing can achieve precision cooperation of automation and intelligence. The final result is the realization of logistics automation, warehousing logistics distribution personnel from 16 to 4 people, structural parts distribution personnel from 37 to 10 people, raw material inventory turnover rate from 34 times / year to 38 times / year, logistics efficiency increased by 200%.

The secret behind the per capita output value reaching 10 million is the overall solution of tree root interconnection, which will finally complete the automation and digital upgrade of each link process.

So when you walk into the renovated Beijing pile driver factory, you will be greeted by 5 major scenes:

1) Craftsman technology empowers robots to achieve intelligent and flexible welding;

2) Machine vision + industrial robots: solve the problem of heavy equipment assembly;

3) Dual AGV linkage heavy-duty logistics, efficient automation;

4) Human-machine collaboration: robots can also become "masters";

5) AI+IIOT to help improve equipment operation efficiency. Readers who are inconvenient to visit offline can also feel it by clicking on the GIF in the special report of Sany Heavy Industry's Xueqiu column. (Note: The website is https://xueqiu.com/1474513401/155759451)

03From a model room to a dream field

Obviously, Sany's goal is not only to build a model room of a lighthouse factory, but also to spread the lighthouse effect widely, and finally realize the industrial transformation to Industry 4.0 by providing the key technologies of the fourth industrial revolution (digitalization, automation, IIOT, etc.).

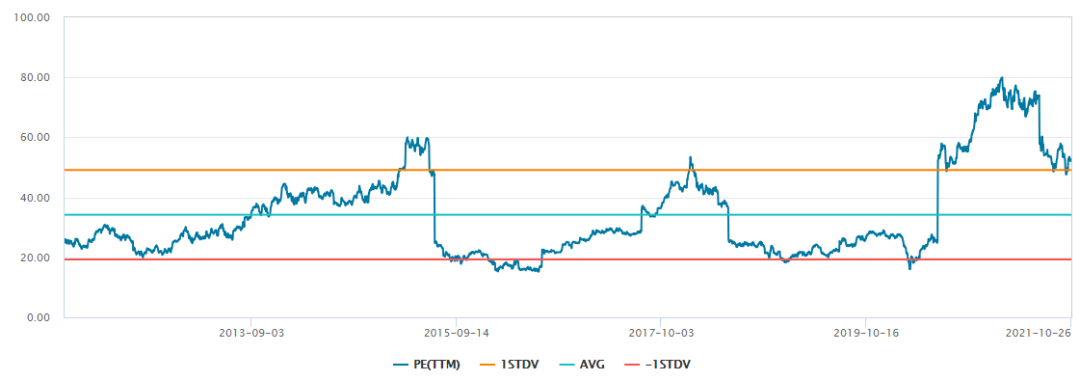

Looking at history, when the industry was transformed to the 3.0 era, Japan's Fanuc played the role of this leader, and became a global automation leader. It is precisely because of this that Fanuc's valuation has successfully broken through the ceiling of the traditional manufacturing industry, and has been stable at about 30 times PE all year round.

At present, the market still labels Sany as a cycle, so Sany Heavy Industry's PE is basically hovering around 10 times; When the market recognizes the company's intelligent logic, when Sany leads the Industry 4.0 revolution, I believe that the market will give it a fair valuation.

Figure 14: Fanuc Historical Valuation Levels, Source: Wind

Returning to the specific route of realizing the dream, we can make the following three prospects:

[1] All-round intelligent transformation within the Sany system

Many of the experiences of Sany Heavy Industry's "lighthouse factory" will first be carried forward in the system.

As of August 2021, Sany Group has realized the interconnection of 55,000 "three-four-five" terminals and 660,000 product-end machines in 30 factories in China. Thanks to the successful experience of the pile driver factory in Beijing, the promotion within Sany Group is believed to be a matter of course.

[2] Empower the whole of China's manufacturing

As mentioned earlier, Fanuc first automates its own internal transformation, and then exports its solutions to various vertical industries to complete the transformation. In the era of industrial intelligence, Sany's dream is far greater than upgrading its own internal manufacturing system, and in the near future, we will see Sany's empowerment of industrial chain partners, industries, and even the entire "Made in China". After all, judging by the performance improvements shown by lighthouse factories, few can resist the temptation of smart solutions.

As a provider of "new pedestals for digital transformation", Tree Root Internet will also go deep into the capillaries of the manufacturing industry to accelerate the upgrading of the industrial base and the modernization of the industrial chain. How big is this space? According to statistics, the added value of China's industrial Internet industry will reach 3.57 trillion yuan in 2020, and the market size is still growing rapidly at a double-digit rate every year, and it will be a large market of 10 trillion yuan in the future.

Figure 15: KPI Improvement Results Observed at Lighthouse Factory, Source: Company Source

[3] Help China to reach a higher level in the new era of global manufacturing competition

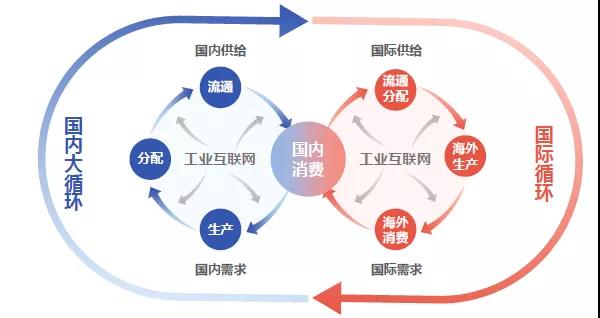

Thinking from a larger perspective, in the manufacturing competition in the new era, the industrial Internet has become a necessary weapon.

The United States, China, Japan, Germany and other manufacturing countries are leading the main track of industrial Internet development, and the development of industrial Internet has gradually become an important strategic highland for global manufacturing enterprises to transform and upgrade and countries around the world to enhance their international competitiveness.

At present, China's industrial Internet output value accounts for 15% of the global output value, second only to the United States 24%, although the results are eye-catching, but still do not match the position of the largest manufacturing country. Platform-based industrial Internet companies like Tree Root Internet may become the most important promoter and enabler of Industry 4.0.

Combined with the macro and micro point of view, under the background of China's policy of deepening reform and opening up, the industrial Internet can effectively promote the domestic economic cycle by promoting China's manufacturing industry to "supplement the chain and strengthen the chain", and cultivate many "specialized, special and new" enterprises by going deep into the vertical field, and relying on the domestic economic cycle system to form a strong gravitational field for global factor resources, promote China's participation in the global value chain to further deepen, and the transformation of participation methods to the middle and high-end fields, so as to realize the new development pattern of domestic and international dual circulation. And successfully occupy a new highland of high value-added industries under the division of labor in the global industrial chain.

Figure 16: Industrial Internet is an important engine for building domestic and international dual circulation, source: White Paper on the Economic Development of China's Industrial Internet Industry (2021)

04Dream Maker: Tree roots are connected

From the micro transformation of the factories within the group, the meso-empowerment of the manufacturing industry, and the macro to help the international competition of the manufacturing industry in the new era, the realization of these three prospects is inseparable from the industrial Internet, which plays the role of a new foundation, that is, a new infrastructure. The dreamer behind it is a platform-based industrial Internet company.

Through the above case of the transformation of the pile driver factory, we have personally felt the power of "overcoming rigidity with softness" in the interconnection of tree roots to hold up the heavy equipment of a large country. Tree Root Internet has built an independent and controllable root cloud platform, built a platform-based industrial APP and industrial data-driven innovative services, and can ultimately provide industrial enterprises with low-cost, low-threshold, high-efficiency, and high-reliability digital transformation services. At the end of last year, Shugen Internet completed a Series C financing of nearly 900 million yuan and became a unicorn enterprise of the industrial Internet, which is a footnote highly recognized by the industry.

In addition to specific vertical industries, Tree Root Internet also combines the industry experience and application scenarios of ecological partners such as industry leading enterprises and industrial chain innovation enterprises to create an industrial chain platform through the P2P2B model of "general platform + industrial ecology", so as to realize the broader and deeper empowerment of the industrial Internet platform, and begin to benefit thousands of households in rural areas and bring changes to all walks of life.

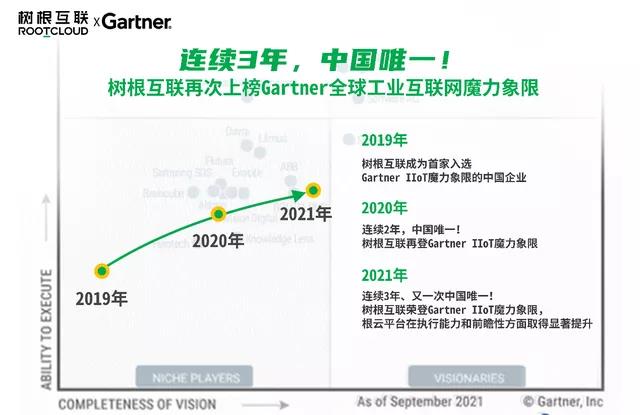

It is precisely because of the reborn changes brought by the dreammaker to the industry that Tree Root Internet has become the only company in China to be listed in the Gartner Magic Quadrant for Global Industrial Internet for three consecutive years. The reasons for the selection are: 1) the ecosystem is open, and the tree root interconnection contributes value to the entire industrial value chain; 2) Technological innovation, forward-looking and outstanding execution ability; 3) Successful landing, world-class lighthouse project illuminates the road to industrial transformation.

"The ideal is a lamp that illuminates the way to walk at night; The ideal is the road that leads you to the dawn. "The dreamer of Tree Root Internet is entering thousands of factories and thousands of families, and we will see that ideals are reflected in reality.

Figure 17: Tree Root Internet has been the only company in China to be listed in the Gartner Magic Quadrant for Industrial Internet for three consecutive years, source: company information

Recommended products

0 comments

Related testimonials

The first in the global industry! CCTV walked into Sany Shaoshan Lighthouse Factory!

2024.10.11

Walk into Sany and explore the "success code" of China's intelligent manufacturing

2023.12.14

People's Daily certification: This represents the highest level of intelligent manufacturing and digitalization!

2023.12.06

0 comments