Hunan businessmen on the ASEAN Silk Road丨Hunan heavy weapons shine in the "country of ten thousand islands"

2024.09.29

Hunan Daily

"Indonesia is the first place where I proposed to jointly build the '21st Century Maritime Silk Road'. In the past 10 years, China and Indonesia have adhered to extensive consultation, joint contribution and shared benefits, complemented each other's advantages, and jointly promoted development, bringing great benefits to the people of the two countries, and becoming an important model for international cooperation on the Belt and Road Initiative. ”

——On October 17, 2023, General Secretary Xi Jinping pointed out during talks with Indonesian President Joko Widodo

The plane crosses the equator and enters the troposphere. A piece of blue came to the face, and the large and small islands were like emeralds inlaid with the sea.

On October 3, 2013, General Secretary Xi Jinping first proposed the initiative of jointly building the "21st Century Maritime Silk Road" in his speech at the Indonesian Congress. As a result, the concept of the "Belt and Road" is familiar to people.

In August this year, the reporter arrived on the island of Java, Indonesia, took the Jakarta-Bandung high-speed railway, and heard the voice of the "Belt and Road" in the first overseas "lighthouse factory" of China's construction machinery - Sany Heavy Industry Indonesia's "lighthouse factory".

On August 12, at the "Lighthouse Factory" of Sany Indonesia, teachers from Hunan demonstrated how to operate excavator equipment to the Indonesian students of the "Sany Class".

“Whoosh”

On the "Belt and Road", the voice of Chinese brands is indomitable

Interviews in Jakarta almost always started with a traffic jam.

In Southeast Asia's largest city, motorbikes are the go-to choice for locals.

People wore helmets and rode motorcycles from brands such as Honda, Yamaha, and Suzuki, navigating through the "army of traffic jams".

"In the 90s of the 20th century, the streets of Jakarta were full of cheap Chinese motorcycles, but the quality was not good, the service accessories could not keep up, and they were soon abandoned by the locals." Liang Jing, national manager of Sany Heavy Industry Indonesia Company, sighed.

In 2005, Sany's sales staff came to Indonesia. "It is not advisable to occupy the market with low prices" is the first lesson they learned.

For the first time, Hunan products want to be sold to Indonesia, not by low prices, by what? took the initiative to give up the "price war", and Sany ate countless closed-door soups.

"We are confident in the quality of the equipment, as long as the customer is willing to try, we will be satisfied." Liang Jing said that in the first few years, the sales team contacted local second-hand construction machinery agents through Indonesian Chinese, and promoted Sany's new equipment by installment payment or post-trial payment.

The traffic moves slowly. Outside the window, Jakarta is building a subway. Inside the enclosure, a Sany rotary drilling drill is working.

Rotary drilling breaks the ground and drives piles to lay the foundation for subsequent construction. With its excellent quality, this product has become Sany's first "hot model" in Indonesia, occupying about 80% of the market share.

Around 2010, excavators,crane, pump truck and other Sany equipment have been sold to Indonesia. However, driven by the lack of large projects, Sany's development in Indonesia has been tepid.

Soon, big opportunities came.

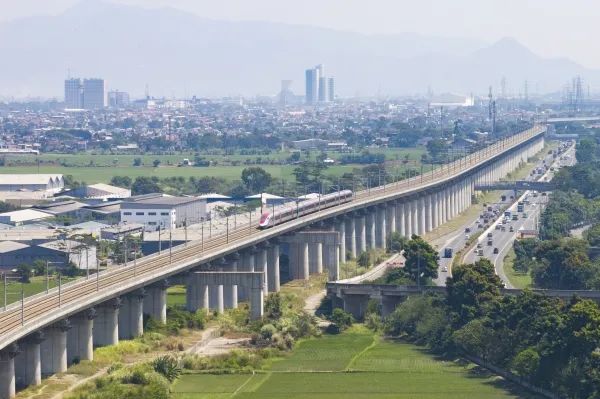

On August 14, in Jakarta, the capital of Indonesia, the Jakarta-Bandung high-speed railway was speeding on the bullet train. The Jakarta-Bandung high-speed railway is the first overseas construction project of China's high-speed railway, which is a full-system, all-factor and full-industry chain。Sany has more than 500 large-scale equipment to participate in the construction of the project.

2In January 016, the first high-speed railway in Southeast Asia, the Jakarta-Bandung high-speed railway, started construction, which became a landmark project of the "Belt and Road" jointly built by China and Indonesia, and was the first construction project of China's high-speed railway with the whole system, all elements and the whole industrial chain landing overseas.

After the traffic jam, Halim Station in Jakarta arrived. The Jakarta-Bandung high-speed railway departs from here and arrives in Bandung, the birthplace of the "Bandung Spirit", with a total length of 142 kilometers.

In the past, there was only one old railway from Jakarta to Bandung, which was built more than 100 years ago, with a speed of more than 50 kilometers per hour and a journey of more than 3 hours.

After the completion of the Jakarta-Bandung high-speed railway, which has a maximum speed of 350 kilometers per hour, Indonesian President Joko Widodo gave it a vivid and resounding name - "Whoosh".

From more than 3 hours to more than 40 minutes, "Whoosh", the sound of a high-speed train whizzing past as it speeds, is also an acronym for "time-saving", "efficient" and "advanced" in Indonesian.

Indonesian guides told reporters that for locals, experiencing the Jakarta-Bandung high-speed railway is a ritual thing. Many Jakarta families will choose a holiday day to take the high-speed train to Bandung to see the volcano and soak in the hot springs.

"There are a total of 13 tunnels on the Jakarta-Bandung high-speed railway, 12 of which were dug by Sany equipment." The Jakarta-Bandung high-speed railway is speeding by, and Liang Jing still remembers the construction process vividly.

Since the start of the construction of the Jakarta-Bandung high-speed railway project, Sany has participated in the construction of more than 500 large-scale equipment, accounting for more than 80% of the total equipment.

The train stopped at the terminal de Karur station, and the in-car radio sounded: "Thank you for taking this train." Whoosh whoosh whoosh,yes!”

Some netizens said that "Whoosh" is the voice of the "Belt and Road".

Jointly building the "Belt and Road", Hunan enterprises have strongly torn off the label that "Made in China" is a "low-quality product", and in Indonesia, "Whoosh" has ushered in many "yes!" of the moment.

Subway, light rail, high-rise ...... Sany's footprint in Indonesia is ubiquitous, with more than 5,000 units of equipment sold in Indonesia every year, and large orders are coming one after another.

In June this year, Sany signed an order for 2,000 excavators with Indonesia's Jhonlin Group, with an estimated value of 1.8 billion yuan, setting a record for the world's largest single excavator.

"Land of 10,000 Islands"

Between the Pacific Ocean and the Indian Ocean, nearly 80 after-sales service outlets have been established

On August 13, in Jakarta, the capital of Indonesia, the Indonesian National Independence Monument is one of Jakarta's most iconic landmarks。

Why is Indonesia the first stop for many Chinese companies to go overseas?

In the few days of the interview, the reporter got a lot of answers - ASEAN's largest economy, with about 40% of its population, area and total economic output, and unlimited market potential.

It is the world's largest coal exporter and the world's largest producer of palm oil...... Indonesia's plan to move the capital has made this land even more tempting.

"The well-known and the unknown are here." Chen Xiaolin, general manager of Sany Heavy Industry Indonesia, said, "I have seen more Chinese construction machinery companies in Indonesia than in China.”

In the face of the "involution and spillover" of domestic brands and the attack of foreign brands, how can Sany stabilize its competitive advantage?

Chen Xiaolin has been working in the Middle East, Southeast Asia and other places for more than 10 years, and understands the needs of overseas customers very well - in addition to quality, after-sales service is very important.

For construction machinery customers, the most expensive equipment is the equipment that stops.

Taking a mining project as an example, equipment failure will directly affect the efficiency of ore mining and cause huge losses to customers.

After-sales service is lightweight, and when you spread out the map of Indonesia, you will know that it is not an easy task.

The island of Java, where Jakarta is located, has long been overwhelmed by over-exploitation of groundwater and sinking ground. Indonesia pins its hopes for future development on the new archipelago, and almost all new and large projects such as mining, agriculture and construction are located outside the island of Java.

Indonesia is known as the "land of a thousand islands", but it actually has 17,000 islands, which is a veritable "country of ten thousand islands". Scattered between the Pacific and Indian oceans, the archipelago spans 5,110 kilometers from east to west, more than twice the distance from Beijing to Urumqi in a straight line.

Even so, Sany still promises that where the equipment arrives, the service is covered.

Before the interview, Chen Xiaolin received good news: in Papua Province, the easternmost province of Indonesia, Sany technicians took planes, boats, helicopters, swamps, and established after-sales service outlets in inaccessible forests to ensure the smooth operation of Jhonlin Group's agricultural projects.

"The world's construction machinery enterprises, only Hunan enterprises, can provide after-sales service there!" Chen Xiaolin said proudly.

Spanning more than 5,000 kilometers, Sany has built nearly 80 after-sales service outlets in more than 10 years.

Sany Jakarta Central Warehouse is the "heart" of a steady stream of accessories to various outlets.

8On the 13th, a batch of filter elements, brake pads, air conditioning compressors and other accessories were unloaded from Tanjung Priok Port, the largest port in Indonesia, and transported to the central warehouse of Sany Jakarta. Indonesian employees put QR code digital labels on the accessories one by one and classified them into boxes. Once an order is sent from the outlet, it can be quickly sorted and shipped.

"'Zhang' taught us to place accessories reasonably, post barcodes, and change packaging...... The sorting efficiency has improved a lot, and the delivery is faster. Indonesian employee Raj said.

Zhang Chenglin, the director of Sany Heavy Industry Indonesia accessories, is the big housekeeper of the "heart". At the end of last year, in order to accelerate the response to customer needs and improve the efficiency of parts distribution, Zhang Chenglin will bring many years of warehouse logistics management experience accumulated in Hunan to Indonesia, and the 3,000-square-meter warehouse will be renovated in two months.

Previously, the warehouse had 20 people working in a row to sort up to 120 orders. Today, the same amount of work can be done by two people.

Under the efficient sorting and distribution, nearly 80 service outlets are responsive, and Sany has reserved more than 500 million yuan of spare parts in Indonesia, so that local customers can also enjoy the Chinese speed of "15 minutes response, 2 hours to the scene, and 24 hours to solve common faults".

“Bagus!”

"Localization is the most important step in globalization"

On August 12, Sany Indonesia's "Lighthouse Factory", the workshop screen displayed the working condition of the equipment in real time.

"Sany is not the first Chinese construction machinery company to come to Indonesia, but it has come from behind and is the first to build a factory in Indonesia." Xu Zaishan, executive vice chairman of the India-China Business Council, said.

Hunan enterprises "go global", not only to build factories, but also to build "lighthouse factories".

The "Lighthouse Factory" is known as the "world's most advanced factory" and represents the world's highest level of intelligent manufacturing.

Sany Indonesia's "Lighthouse Factory" is nearly 10,000 square meters, and the main processes such as man-machine highly collaborative assembly and logistics commissioning have realized full network connection and unmanned production.

Song Ruixue, general manager of Sany Heavy Industry Indonesia Machinery Co., Ltd., can't wait to "show off the digital big screen".

The digital twin system built by the "lighthouse factory" is like the "twin brother in the cloud" of the factory.

In the factory, AGVs (Automated Guided Vehicles) shuttle between the production line and the warehouse; On the screen, the warehouse situation is updated in real time.

At the workshop site, the automatic welding robot operates accurately; On the large data screen, the welding data has been captured to the background, and the production status is clear at a glance.

"This is a twin system that we have developed independently, so not only can the Indonesian office know the operation of the factory, but also the Changsha 'lighthouse factory' can also be viewed simultaneously. Factories and headquarters can adjust equipment and manpower investment in a timely manner according to the capacity load to improve production efficiency. Song Ruixue said.

Xiang Wenbo, chairman of Sany Group, believes that enterprises should have a sense of crisis of "either turning over or capsizing", and digital intelligence and globalization are important transformation directions for Sany.

Indonesia is Sany's largest single country market overseas. While Sany Indonesia's "Lighthouse Factory" is making great strides on the road of digital intelligence, it is also an important "test field" for Sany to explore global transformation.

Song Ruixue, who has worked for Japanese companies for more than 20 years, believes that "localization is the most important step in achieving globalization.”

The localization of Sany Indonesia's "Lighthouse Factory" started with changing the working language.

At the beginning of the construction of the factory in 2022, the factory recruited local Chinese as translators. However, in the absence of the translator, the Indonesian employees could not understand Chinese and were unable to fully devote themselves to the construction of the factory.

In June 2023, the first phase of the plant will be put into operation, and the production capacity will begin to climb. Song asked all Chinese employees to speak English and learn Indonesian.

The results are immediate. Indonesian employees began to speak at the meeting. "They like me to say 'Bagus' the most, and they're willing to do their part to make the factory more 'Bagus.'" Song Ruixue said.

"Bagus" is the Indonesian word for "good". One year later, Indonesian workers are working 50% more efficiently, and the factory's production capacity has increased from four to 12 units a day. In September this year, the second phase of the plant was also put into use.

Currently, Sany has more than 1,200 employees in Indonesia, 90% of whom are Indonesians. After realizing the localization of employees, Sany is still working hard to localize the supply chain.

On August 11, the reporter followed Aliv and Tommy and drove for more than 40 minutes to the Murinda Machinery Factory. This is the fifth time they have come to this factory.

Alif's main job is to help Sany find local production suppliers. He smiled and "complained", Sany's high standards made him very stressed.

Aliv thought that the seemingly ordinary excavator deflected head would be no problem if it was handed over to the 50-year-old Murinda Machinery Factory for processing. However, the experienced factory, the first 4 processing trial production failed to meet the high-precision needs of Sany.

Tommy is a technician at Trinity. During this period, he worked with Chinese technicians to develop a complete machining training process for steel mills. Drawings, welding processes, assembly ...... A completely new set of production standards has been set for suppliers.

Such an abrasive cooperation, but the Murinda Machinery Factory is very cooperative. When he arrives at the factory, Tommy double-checks the machining dimensions of each hole with a vernier caliper, and finally makes an "OK" gesture to the other party.

Since last year, Sany has empowered local factories with high-precision, high-efficiency and high-stability Chinese manufacturing processes and cultivated more than 10 local suppliers.

"Sany is a truly global company. In addition to business cooperation, it has also helped us to improve our technology to a higher level. Condero Sugihanto, head of the Murinda Machinery Factory, gave a thumbs up and said, "Chinese brand, 'Bagus'!"

High-end interviews

Indonesian Hunan enterprises go to the world together

——Interview with Xu Zaishan, Executive Vice Chairman of the India-China Business Council

Hunan Daily all-media reporter Huang Tingting

World Diving Destination - Manado, Indonesia.

"Indonesia is the largest country in ASEAN, with abundant resources and vast space, which is very suitable for Hunan enterprises to show their strengths." In mid-August, Xu Zaishan, executive vice chairman of the India-China Business Council, was interviewed by a reporter from Hunan Daily, and while welcoming the landing of Hunan enterprises, he also repeatedly mentioned the word "huddle".

In recent years, Indonesia has formulated a strategy to localize the industrial chain. Large enterprises such as Sany Heavy Industry can build factories locally, lay out the industrial chain, and gradually realize localization, while it is becoming more and more difficult for small and medium-sized enterprises to go overseas on their own. Xu Zaishan said: The old Chinese and the old overseas Chinese rely on the hometown associations to be closely linked together, communicate with each other, and develop together. Now it's time to harness the power of the Chamber of Commerce.

Before 2013, most Hunan people came to Indonesia to do fireworks, bags and other businesses, and worked alone. With the implementation of the "Belt and Road" initiative and the rapid development of Indonesia itself, there are more and more large projects, and large and medium-sized enterprises have come one after another.

In December 2023, the Hunan Chamber of Commerce in Indonesia was established, and Hunan enterprises have their own bases in Indonesia. According to preliminary statistics, in Jakarta alone, there are more than 110 large-scale Hunan enterprises, and there are also many Hunan people in Surabaya, Bandung and other places. This year, Hunan enterprises that came to Indonesia to inspect the market are showing a "blowout" trend.

"Sany first came to Indonesia and relied on the local Chinese to gradually open up the market. Today, the Indonesian Hunan Chamber of Commerce can provide assistance in legal, tax, site selection and other aspects to help enterprises avoid risks and avoid detours for new Hunan enterprises. Xu Zaishan said, "We should unite all the Hunan enterprises in Indonesia, and then combine them with the chambers of commerce in other provinces to closely contact our old Chinese groups, become bigger and stronger together, and go to the world together." ”

Reporter's Notes

Teach people to fish, win-win cooperation

Huang Tingting

On August 12, Sany Indonesia's "Lighthouse Factory", Indonesian workers were busy on the excavator production line. The pictures in this edition are all photo reports by Hunan Daily all-media reporters Gu Pengbo, Zou Shangqi and Tong Di

Sany Indonesia's "Lighthouse Factory", the all-glass curtain wall glows with a sapphire-like luster, and Indonesian employees affectionately call it "Blue Building". Next to the Blue Factory, a yellow-roofed Chinese-style building is Sany's global training center, known as the "Yellow Building".

At the time of the reporter's interview, English with a Hunan accent wafted out of the "yellow building", and two training teachers from Trinity Institute of Technology, Yi Yanchi and Xie Lanhua, were teaching students from Karawang University in Indonesia.

In July this year, the "Trinity Class" jointly organized by Trinity Institute of Technology, Karawang University and Sany Indonesia was launched. This is the first time that a Chinese construction machinery company has cooperated with an overseas university to run a school.

The first batch of 40 students will undergo a four-month intensive training, after which the students who pass the assessment will be able to intern and work in various departments of Sany Indonesia.

"Mechanical engineering is my dream job. I will study hard and try to stay in Trinity. 22-year-old Magada said that Sany's teachers are very experienced, will teach the principles of excavator electricity and engines, and will also let students get hands-on operation, and everyone can get started quickly.

On the Jakarta-Bandung high-speed rail project, Sany has also trained thousands of manipulators, most of whom are villagers from villages along the high-speed railway. At present, many villagers have found jobs and their incomes have doubled.

The industry experts trained by Sany for Indonesia will obviously not all stay in Sany, but they will devote themselves to Indonesia's construction machinery industry and work together to strengthen and expand the industry cake, and Sany can also benefit from this.

This year marks the 11th anniversary of the Belt and Road Initiative. Practice shows that for Chinese enterprises, the old Chinese proverb "it is better to teach people to fish than to teach them to fish" has always been the only way for contemporary enterprises to develop overseas in the long run.

Content source: Hunan Daily, New Hunan Client

Related testimonials

Special attention to the two sessions! CCTV's "Economic Half Hour" focuses on Sany's "chain breakthrough"

2025.03.10

CCTV "Focus Interview": Reveal the technical code of Sany Shaoshan Lighthouse Factory

2024.11.02

Sany has repeatedly appeared on "News Network"! Digital transformation accelerates the layout!

2024.10.22

0 comments