Let's talk about intelligent construction丨Changsha Yunhu Villa commercial and residential project online interaction is opened

2022.05.17

Trinity Construction

The second phase of the "Talking about Intelligent Construction" theme series of activities - "Changsha Yunhu Villa Commercial and Residential Project" online interaction came as scheduled [48-hour interactive period: 14:00 pm on May 17 - 14:00 pm on May 19], encouraging all industry experts to put forward more constructive optimization suggestions and solutions, if creating faster, better and cheaper economic value, we will share with you 50% of the value contribution. In addition, interested industry "players" or those who want to participate in the EPC bidding of the project, this event record is the admission ticket to participate in the project, please actively contribute your opinions!

Last week, we released the "Sany Group Beijing Nankou A8 Plot Project Plan" received more than 200 interactive messages, the content of which was called "a message board worth millions" by industry insiders. Thank you for your many optimization suggestions, we have selected 34 beneficial value messages to share and award live on the evening of May 13, which have been praised by the majority of industry insiders.

【Live Broadcast Preview】At 19:00 p.m. on May 20th, the live broadcast room will be judged for the grand prize! We have prepared generous gift cards and lucky bags for all industry experts and folk experts, and we look forward to your participation!

01Project information

Overall overview: The project Julongping & Free Trade Section, the subway entrance of Caojiaping Station of Line 6, strengthens the hydrophilia of community life through the design of visual corridors and garden trails; At the same time, the lake is linked with the surrounding buildings, trees, and grasslands, weaving a public space that seems to grow infinitely, making people feel the urge to "retreat" when they stand here. It also built about 300,000 square meters of large commerce, signed a contract with the primary and secondary schools affiliated to the High School Affiliated to Normal University, privately enjoyed about 120,000 square meters of inner lake, and achieved about 3.13 million square meters of lake living ideal city. Start building the club in advance, and the natural lake, school, native park and business, the five major supporting facilities will be implemented in advance to achieve a life that can be seen and touched.

Customer information: Changsha Yunhui Real Estate Development Co., Ltd

Construction site: Changsha City, Hunan Province

Main function: residential

Structural form: shear wall structure

Fortification intensity: 6 degrees (0.05g)

Height: 63.00m (take 28# as an example)

Number of layers: 21 layers (take 28# as an example)

Floor height: 3.0m (take 28# as an example)

Sales method: commercial housing

Delivery Method: Fully Decorated

Green Building Star: Green Building Basic Level

Active use of prefabricated construction area: 65,000 m2

Floor area: 76,500 m2

Prefabricated construction requirements: none

Calculation standard of assembly rate: "Evaluation Standard for Green Prefabricated Buildings in Hunan Province" DBJ43/T332-2018 and supplementary provisions

Policy Requirements

1. "Changsha City Prefabricated Housing Construction Project Construction Management Rules" Changzhu Jianfa [2018] No. 63 pointed out: for commercial housing projects that meet the requirements of prefabricated buildings and obtain land use rights by way of transfer, obtain land use certificates and construction project planning permits, and invest more than 25% of the total investment in development and construction, or complete the basic project to reach plus or minus zero, under the premise that the construction progress and completion delivery date have been determined, the pre-sale registration and the pre-sale license of the commercial housing can be obtained. Except as otherwise provided by laws and regulations.

2. The "Implementation Rules for the Financial Subsidy of Prefabricated Buildings in Changsha City" Changzhu Jianfa [2019] No. 29 pointed out that for new commercial housing projects where the construction unit actively adopts prefabricated building technology to build and the assembly rate of a single building reaches 50% (inclusive) or more, the construction unit can receive a subsidy of 100 yuan/square meter. (It is recommended that the policy be continued, and the subsidy will be sought)

03Solution selection

If the first phase of Yunhu Villa is used, it is in the form of full cast-in-place.

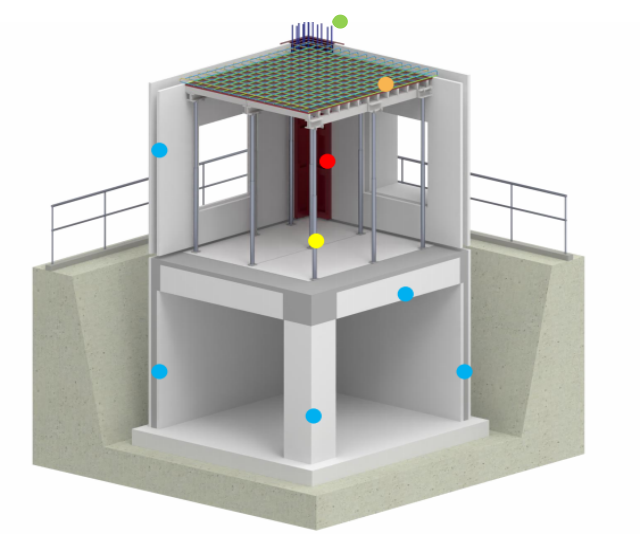

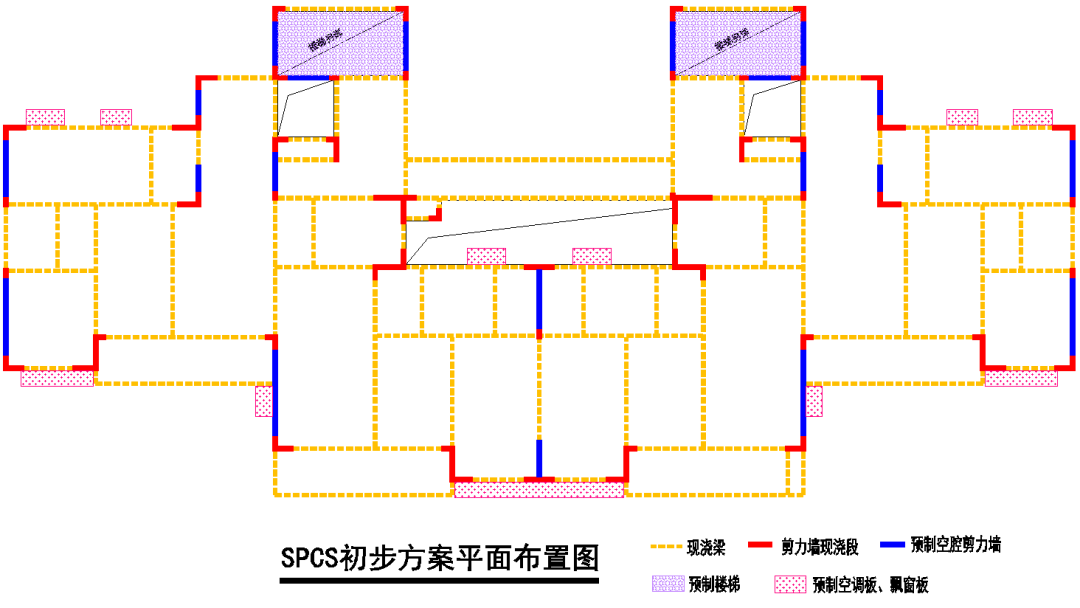

In order to achieve better quality and efficiency advantages,Trinity ConstructionIt is recommended to take the initiative to adopt the prefabricated construction method and implement the prefabricated building system solution of "cavity lap plus post-casting, equivalent heterogeneous and fast saving", and the scheme comparison is as follows:

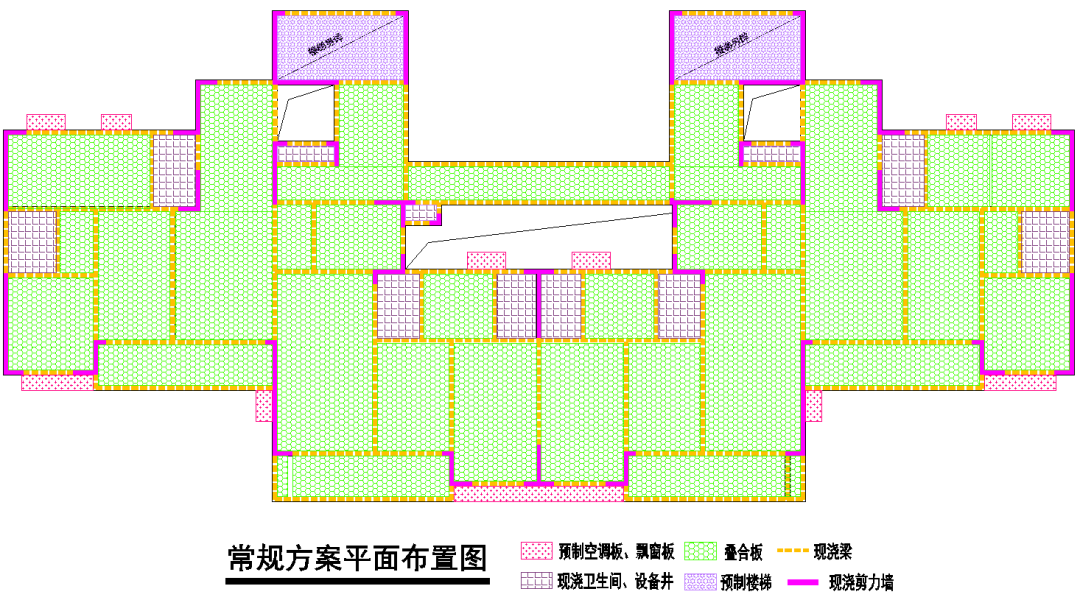

Local general scenario

System features: "traditional full cast-in-place"

Layout of the general scheme

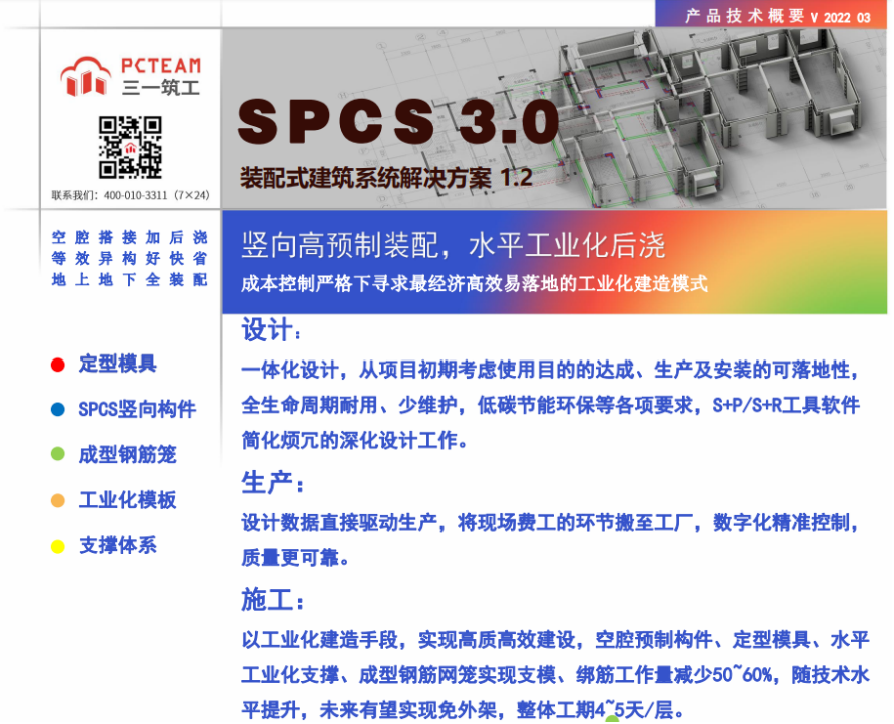

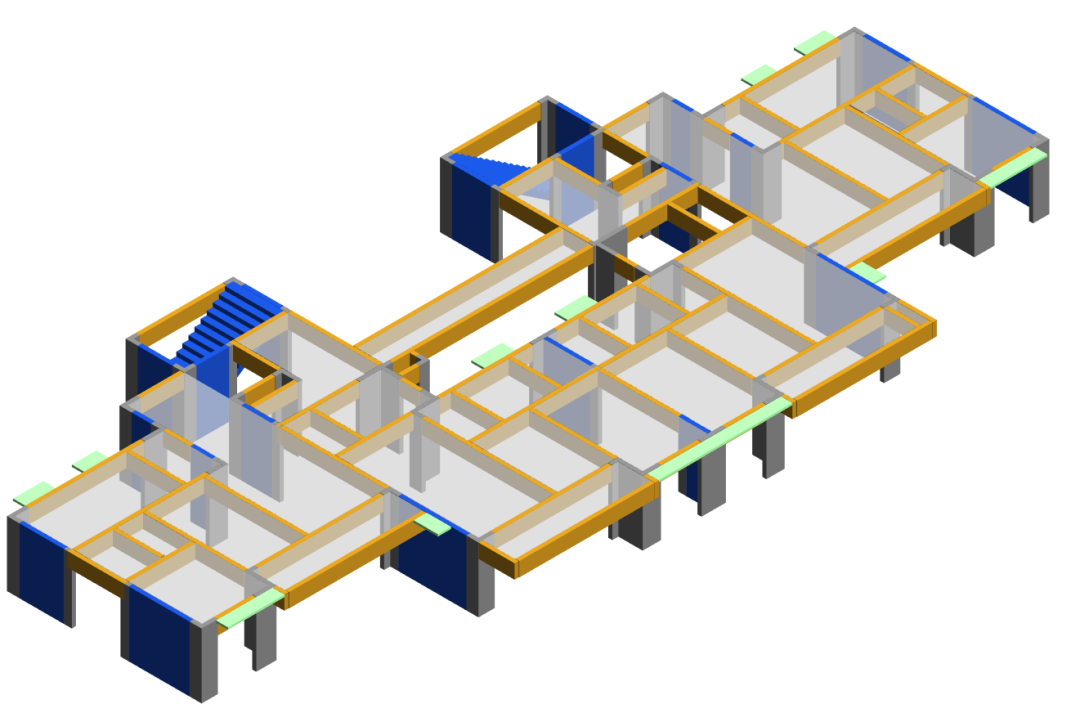

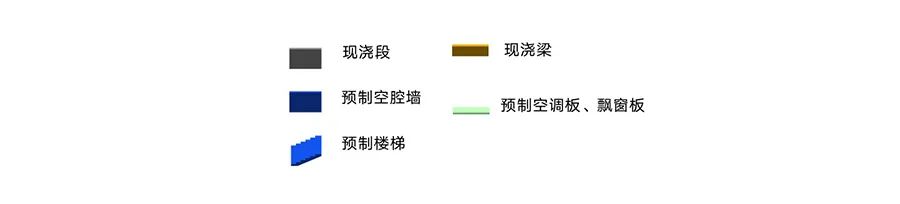

Preliminary plan for intelligent construction

“Apply standards

T/CECS-579-2019

DBJ 43/T 376-2021

Conclusion: The assembly rate is 51.5%, and the industrialization index of the main structure is 78.1%

Note: 1. The industrialization index of the main structure refers to the ratio of the amount of concrete to the total amount of concrete used by off-site manual operation of the main structure (tying steel bars, supporting formwork, erecting scaffolding, etc.). The prefabricated part of the floor slab, the prefabricated cavity component and the post-cast concrete in the cavity can also be counted, and the cast-in-place shear wall and post-cast section on site are not included in the molecule.

2. SPCS system scheme applies SPCS+P/N/R design software to realize intelligent splitting and deepening design; SPCI-PMES/RMES/CPTS independent industrial software analyzes the 3D data of components to drive factory production; PCM management software and cockpit, one piece and one code full control; PCTEAM's "full cycle, all elements, all roles" project management platform replaces imports; The digital twin delivery of the whole process of building design, production and construction provides data support for subsequent building operation and maintenance. Sany makes use of the technical advantages accumulated for a long time in the engineering field to achieve a full score of 3 points in the application of intelligent technology, assembly construction, and new technology application.

Quality advantage

Compared with the local conventional scheme, the preliminary intelligent construction scheme has the following technical advantages:

√ Cavity wall advantage W1

1) Good structure and high quality. The intelligent manufacturing components are generally safe, water-free, and have good appearance quality, which can realize no plastering and realize that the structure is the building; Convenient maintenance throughout the life cycle;

2) Fast installation and delivery. The use of equivalent heterogeneous steel cage/mesh can reduce formwork and steel bar binding, and the secondary structure is inserted in advance and the amount of decoration work is small, which can shorten the construction period of the standard layer by about 3 days/layer; The comprehensive construction period can save 54 days;

√ Horizontal industrialization post-pouring advantage P1

The industrial production of ribbed mesh sheets and on-site laying greatly reduce the amount of on-site operations and improve construction efficiency.

√ Environmental protection advantages: SPCS intelligent construction solution is adopted, which is low-carbon and environmentally friendly. According to the calculation principle of the "Building Carbon Emission Calculation Standard", every square meter of SPCS intelligent construction solution is equivalent to one tree of variety. The prefabricated construction area of this project is 65,000 square meters, which is equivalent to 65,000 trees of various kinds.

√ C-end experience advantages: 1) The whole process of one piece and one code can be traced, and the whole process of intelligent construction can be visualized; 2) BIM model modeled in advance, decoration design can be carried out in advance; 3) Provide model data to facilitate later building renovation and property operation and maintenance.

Benefits

√ Fast return of funds: Compared with traditional cast-in-place, pre-sale can be achieved with plus or minus zero, and the pre-sale can be achieved 3 months in advance, and the return of funds is faster, and the benefit advantage is 100 yuan/㎡;

√ Increase the selling price: the assembly rate reaches 50%, and the construction of high-quality prefabricated demonstration projects can strive to increase the selling price by 300 yuan/㎡;

√ Policy subsidy: It is recommended to continue the document [Changzhu Jianfa (2019) No. 29] to encourage prefabricated buildings and strive for a reward of 100 yuan/㎡;

√ Optimal design: Combining intelligent home improvement equipment, realizing pipeline separation through integrated design: less embedded pipelines, easy replacement, no slotting, can save about 10 yuan/㎡; For example, in the later stage, through docking with the traditional design, optimizing the layout of vertical components, and realizing the elimination of external frames through complete sets of technical systems such as corner shaping molds, industrialized protective enclosures, and prefabricated cantilever components, the cost can be saved by 50 yuan/㎡;

√ Short construction period: the prefabricated components are light in weight and fast in construction, which can shorten the construction period of the standard layer by about 3 days/layer, save the comprehensive construction period of 54 days, and save the tower crane, support leasing fee and management fee of 20 yuan/㎡;

√ Labor and material saving: By simplifying the processes of connecting nodes, tying steel bars, supporting templates, plastering, etc., the material cost of vertical components (cavity walls) is increased by about 80 yuan/㎡; Through the horizontal industrialization of horizontal components, the labor and material costs can be saved by 10 yuan/㎡ compared with the conventional scheme;

General conclusion of comprehensive benefit advantages: Considering the above advantages, if the above policy incentives and technical solutions are all realized, the cost of the preliminary plan of intelligent construction can achieve a comprehensive benefit advantage of 510 yuan/㎡ compared with the original plan, and the total construction area of the prefabricated type is 65,000 square meters, and the final comprehensive income will reach 33.15 million yuan.

Welcome everyone to the official account of Sany Construction to leave a message to participate in the activity:

0 comments