The first batch in the country! No. 1 in the industry! Three of Sany factories were rated as excellent smart factories

2025.01.24

Sany Group

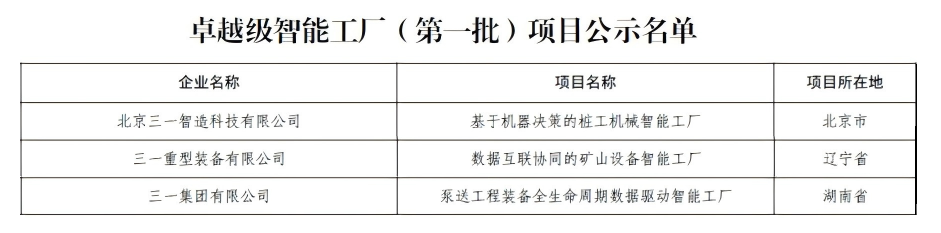

Recently, the list of the first batch of excellent intelligent factories of the Ministry of Industry and Information Technology ended the publicity, and Sany stood out with its excellent intelligent manufacturing performance, and its three factories were successfully selected, the number of which was the first in the industry, setting a national leading demonstration benchmark for industrial transformation and upgrading.

They are: machine-based decision-makingPiling machinerySmart factory, intelligent factory of mining equipment with data interconnection and collaboration, and data-driven smart factory of the whole life cycle of pumping engineering equipment.

In October 2024, the Ministry of Industry and Information Technology, the National Development and Reform Commission, the Ministry of Finance, the State-owned Assets Supervision and Administration Commission of the State Council, the State Administration for Market Regulation, and the National Data Bureau jointly launched the 2024 smart factory gradient cultivation action, and built a smart factory gradient cultivation system according to four levels: basic, advanced, excellent and pilot. This announcement is the list of the first batch of "excellent smart factories", and on this basis, we will further cultivate and select "pilot smart factories" in the future.

The three factories were awarded the first batch of "excellent smart factories", which not only represents the country's high recognition of Sany's intelligent manufacturing level, but also fully affirms Sany's exemplary and leading role and promotes the high-quality development of China's manufacturing industry.

The intelligent factory of piling machinery based on machine decision-making realizes 35 intelligent scenarios such as digital twin factory, process digital design, flexible configuration of production line, intelligent scheduling and scheduling, intelligent warehouse management, intelligent operation and maintenance of equipment, and intelligent energy management, covering 87% of the scenarios in the gradient cultivation action of smart factories, and builds a business operation platform in the fields of marketing, R&D, manufacturing, supply chain, and service to achieve process-driven, online collaboration, and data intelligence. Build a unified digital foundation, build an intelligent manufacturing ecosystem, build a manufacturing "super brain", and build a delivery system with measurable resources, predictable bottlenecks, process monitoring, and change control, so as to realize data-driven business and machine decision-making actions.

The intelligent factory of mining equipment with data interconnection and collaboration uses big data, industrial Internet and robot technology to build an intelligent manufacturing factory with 6 islands, 3 lines and 1 workshop, and builds a digital manufacturing operation platform with MOM, WMS and production line central control system as the core, applies advanced scheduling tools to realize automatic planning of plans, uses Sanxian video visualization technology to drive automatic distribution of line-side materials, and applies robots and automatic processing units to realize the automation of work reporting to support the production and operation of the entire lighthouse factory. At the same time, it optimizes the overall layout of production, integrates MOM, WMS, AGV scheduling system, production control system of each production line, etc., builds an automated and intelligent robot smart factory, and improves the equipment utilization rate by more than 50% through the interconnection of three and four tables.

Based on data-driven, the data-driven intelligent factory of the whole life cycle of pumping engineering equipment realizes the integration of product production, marketing, research, storage and after-sales service, and comprehensively promotes the intelligent production of high-end pumping construction machinery - "production line automation, operation digitalization, collaborative networking, and intelligent decision-making". Through the integration and application of information technology such as the Internet of Things, big data, and cloud computing, we can break the data island, realize the interconnection of equipment, personnel and products, and comprehensively improve the operational efficiency of production, management, service, logistics and other links in real time, comprehensively improve the level of automation and digitalization, and promote the intelligent upgrading of management systems, production lines and core components, with the numerical control degree of key equipment reaching more than 90% and the automatic collection rate of production data reaching 98%.

In the future, Sany will continue to implement the digital intelligence strategy, actively promote the digital and intelligent transformation of itself and its industry chain partners, and contribute more wisdom to the high-quality development of China's intelligent manufacturing!

0 comments