Sany Heavy Industry Sany Heavy Industry Co., Ltd. (SH:600031)

Trinity International Sany International (HK:00631)

Sany Renewable Energy Sany Renewable Energy (SH:688349)

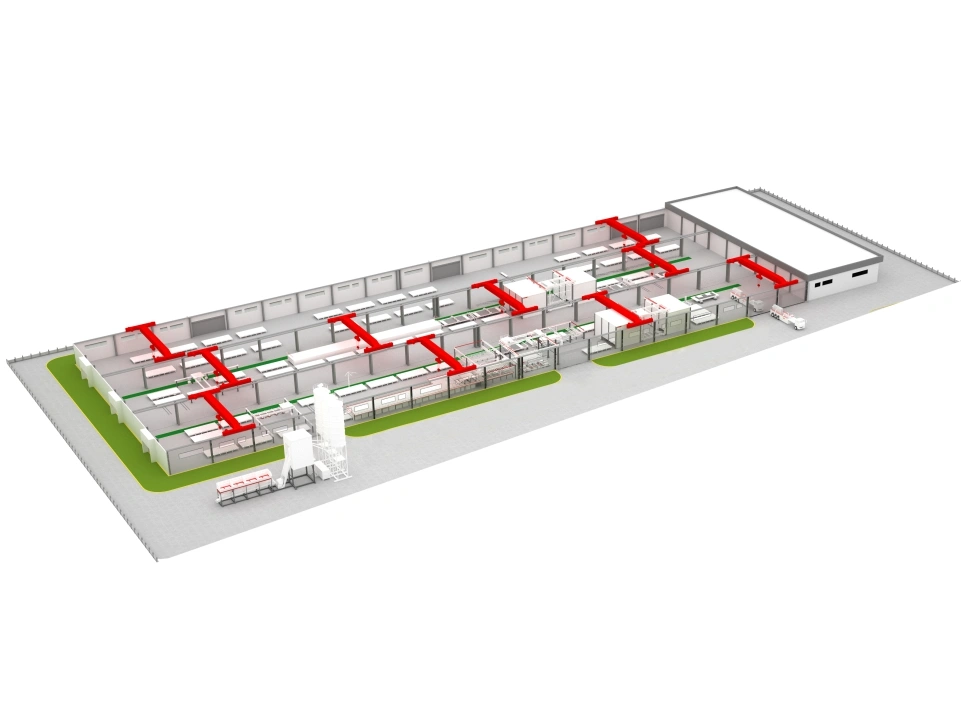

AAC production line

SACE intelligent AAC equipment

Production of ALC sheets and blocks

High degree of intelligence

Energy saving and environmental protection are super humanized

Applicable working conditions

Product BrochureProduct Details

Construction case

Performance parameters Product selling point

Producible components

Autoclaved aerated concrete slabs, autoclaved aerated concrete blocks

Management system

ALC Production Management System

Equipment composition

Cutting machine, flip demoulding machine, ball mill, breaking machine, etc

Product Use:

Production of ALC sheets and blocks

Product Features:

High degree of intelligence

Product Advantages:

Energy saving and environmental protection are super humanized

1. Efficient and reliable

The comprehensive application of core automatic control technology has greatly improved production efficiency. The production line has a cycle time of 3-5 minutes, which reduces the demand for operators by 30% and greatly reduces the production cost.

2. Low carbon and energy saving

The self-developed workshop energy management system and waste heat recovery, water, electricity and steam can be monitored online, save water and electricity by 5%-8%, and waste heat recovery can save natural gas by 10%-15%, which is low-carbon and energy-saving, and reduces customer production costs.

3. Worry-free operation

Industry 4.0 is deeply applied to digital factories, and independently developed AMES production management system, ACM production, sales and inventory management system, digital factory cockpit, APP-based digital quality inspection, etc., to escort factory operations.

4. Delivery without worries

Strong and advanced intelligent manufacturing capabilities, Sany's own professional installation team, and information-based online collaboration platform can achieve high-quality delivery of the standard line within 120 days, and realize the opportunity to win quickly for customers.

The comprehensive application of core automatic control technology has greatly improved production efficiency. The production line has a cycle time of 3-5 minutes, which reduces the demand for operators by 30% and greatly reduces the production cost.

2. Low carbon and energy saving

The self-developed workshop energy management system and waste heat recovery, water, electricity and steam can be monitored online, save water and electricity by 5%-8%, and waste heat recovery can save natural gas by 10%-15%, which is low-carbon and energy-saving, and reduces customer production costs.

3. Worry-free operation

Industry 4.0 is deeply applied to digital factories, and independently developed AMES production management system, ACM production, sales and inventory management system, digital factory cockpit, APP-based digital quality inspection, etc., to escort factory operations.

4. Delivery without worries

Strong and advanced intelligent manufacturing capabilities, Sany's own professional installation team, and information-based online collaboration platform can achieve high-quality delivery of the standard line within 120 days, and realize the opportunity to win quickly for customers.

Due to the continuous update and progress of technology, the differences between technical parameters and configurations and the actual product shall be subject to the actual product; In addition, the machine on the picture may include additional equipment.

Parameter comparison

Recommended products

See them all