Sany Heavy Industry Sany Heavy Industry Co., Ltd. (SH:600031)

Trinity International Sany International (HK:00631)

Sany Renewable Energy Sany Renewable Energy (SH:688349)

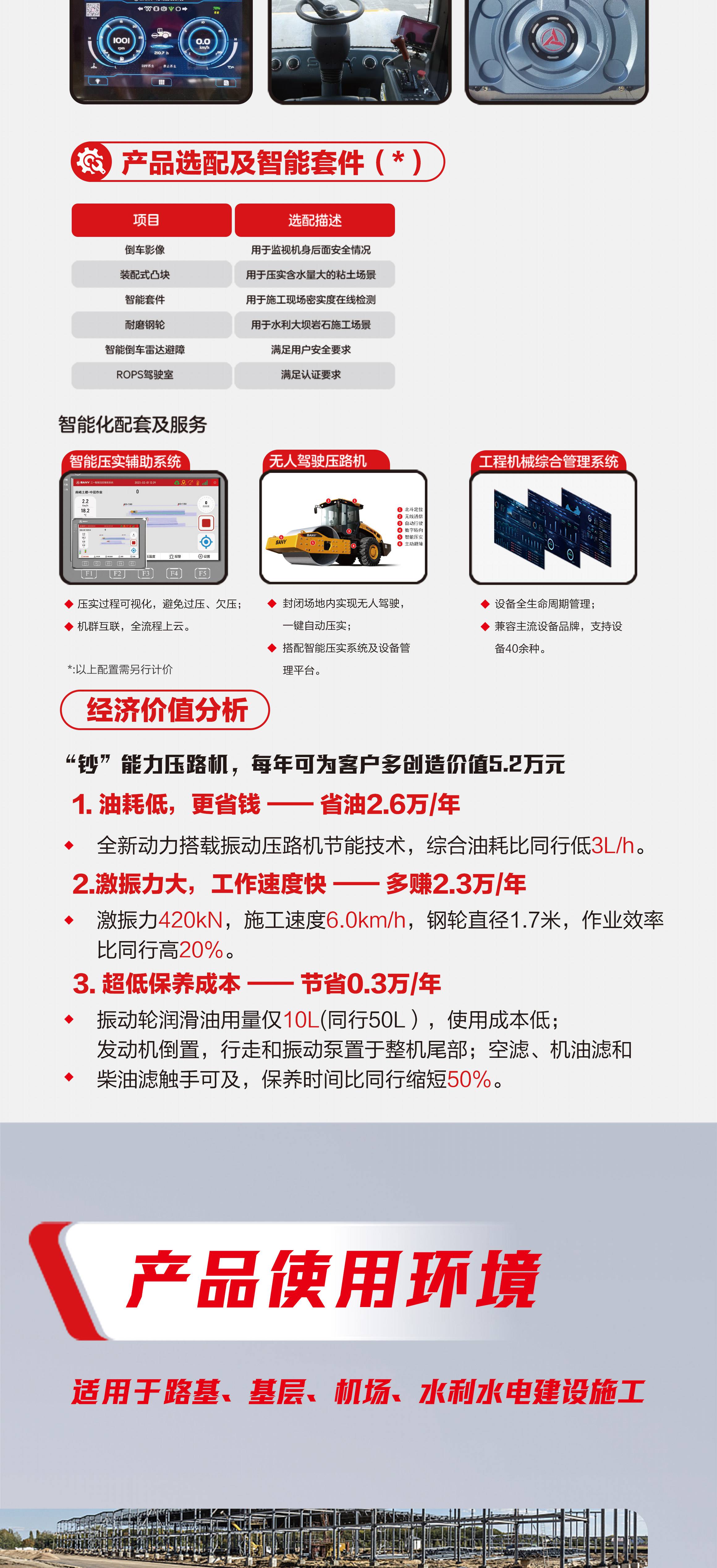

SSR260AC-10H

26 tons C10 China IV full hydraulic single-drive single-drive single-drum roller

155kW

26000kg

420/300kN

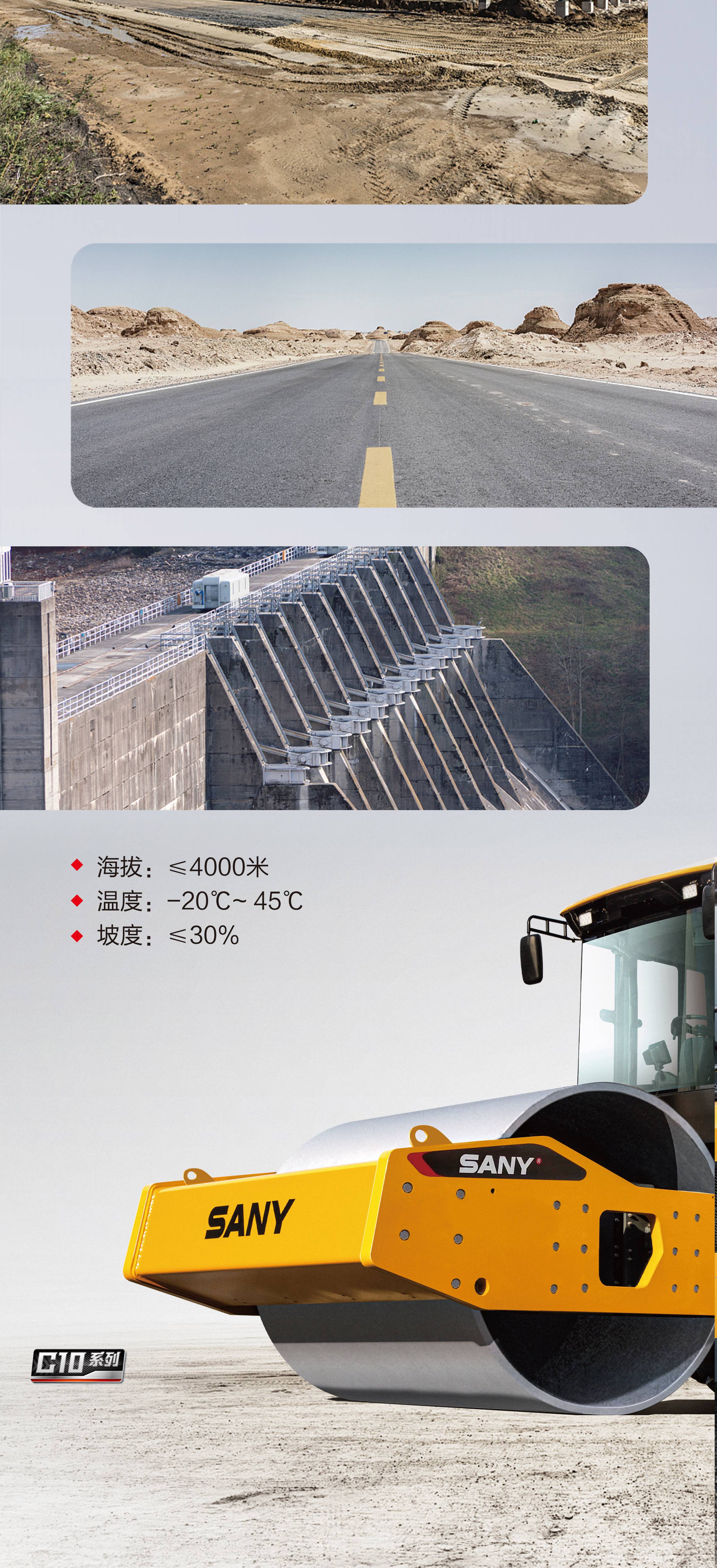

Applicable working conditions

Product Brochure Earthworks

Earthworks Municipal utilities

Municipal utilities highway

highwayProduct Details

Construction case

Performance parameters Product selling point

Engine make and model

Shangchai SC7HG4

Rated power

155kW

Quality of work

26000kg

Front and rear load distribution

13000/13000kg

Vibration frequency

27/32Hz

Vibration frequency Low/High

27/32Hz

Excitation force Large/small

420/300kN

Amplitude Big/Small

2.1/1.1mm

Theoretical climbing ability

30%

Rated power

155kW

Quality of work

26000kg

Excitation force

420/300kN

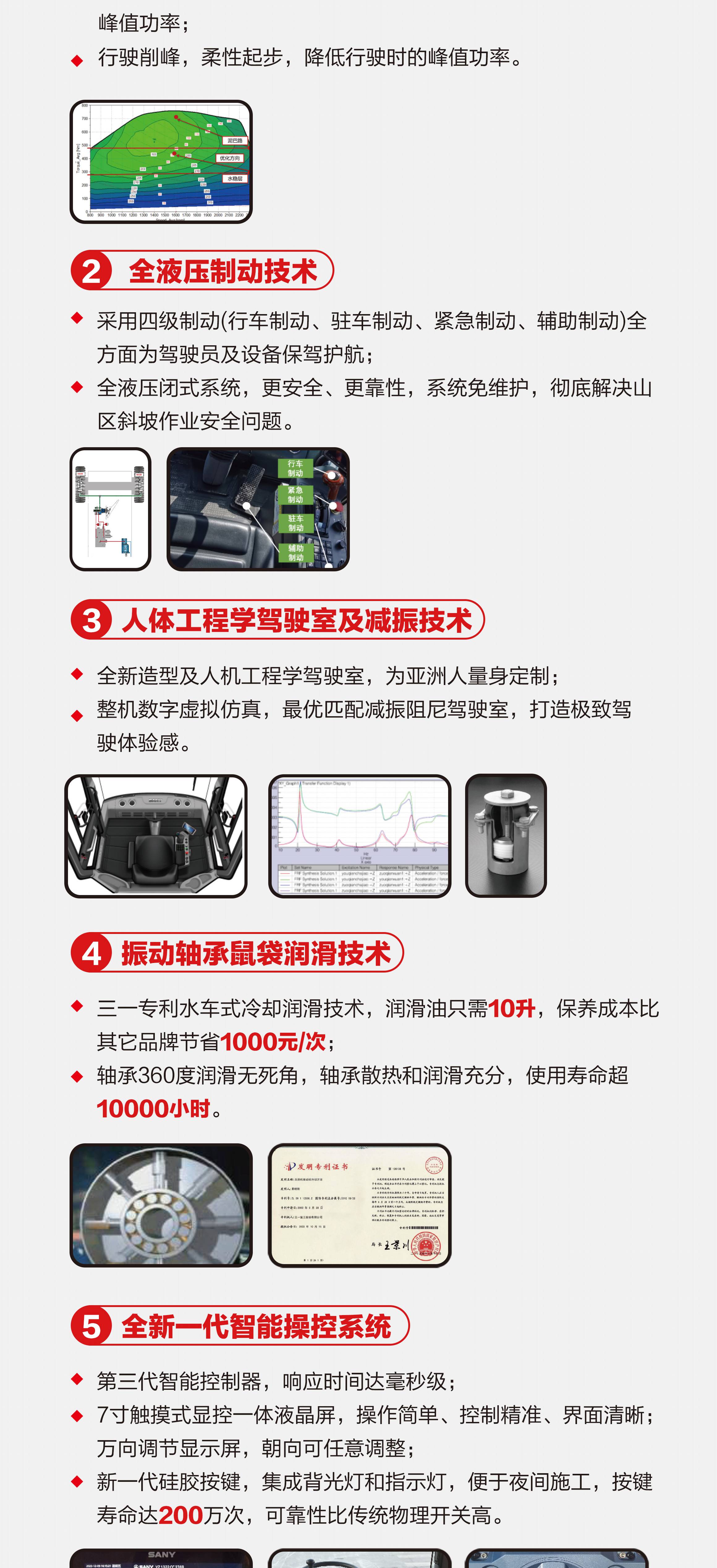

Lower fuel consumption

Save 200 yuan per day: the new power is equipped with vibratory roller energy-saving technology to ensure that the load rate of the whole machine is maintained in an efficient working area of 60%-80%, and the fuel consumption is 16.7% lower than that of peers, saving 200 yuan per day (calculated according to 8 hours/day, 5km/h vibration compaction);

Lubricating oil only needs 10 litres: Diesel is cheaper, lubricating oil is more economical, and the lubrication technology of waterwheel bearings requires only 10 litres of drum oil, which is only 20% of that of its peers.

More efficient

15% higher construction efficiency than peers: excitation force 420kN (peer 374kN); Fully hydraulic, electronically controlled, continuously variable speed technology for compaction speeds of up to 6.0 km/h (5.5 km/h in the industry);

Sensitive operation: The "core" generation of intelligent controllers has 3 times faster computing speed, reaching millisecond level, comparable to the response speed of intelligent electric vehicles.

Safe and reliable

Safety and lifelong worry-free: four-stage braking (service brake, parking brake, emergency braking, auxiliary braking) ensures that the equipment and construction process have zero risk and zero accidents, and the industry's unique all-hydraulic wheel side disc braking system is reliable and maintenance-free;

Reliable, durable and value-preserving core components: A new generation of predictive maintenance technology monitors the rear axle temperature, hydraulic oil cleanliness, engine oil, water vapor in real time, and intelligently prompts maintenance and problem solving to ensure the healthy and stable operation of the equipment.

Due to the continuous update and progress of technology, the differences between technical parameters and configurations and the actual product shall be subject to the actual product; In addition, the machine on the picture may include additional equipment.

Parameter comparison

Recommended products

See them all