The main structure of the SPCS+SPCH system of 18# building in Loudi Sanyi Block --- was crowned with a golden roof

2022.12.12

Trinity Builders

Recently, with the completion of the concrete pouring of the 18# machine room floor of the second phase of the Loudi Sanyi Block project,Trinity BuildersThe main building combining the SPCS3.0 technology system and the SPCH space smart home design system was officially capped. Through the technology of SPCS3.0 "cavity lap plus post-pouring, equivalent heterogeneity and fast saving", the project building structure has good safety, good quality, environmental friendliness, saving construction period, labor and construction and safety costs.

1. Project overview

1. The second phase of the Loudi Sanyi Block project is located in Loulian Highway, Louxing District, Loudi City, west of Taihe Road and east of Qinfeng Road; The project is developed by Sany Zhushengyuan Real Estate Development Co., Ltd., Zhejiang Urban Construction is the general contractor, and Sany Construction provides prefabricated components and installation construction. At the same time, Sany Construction provides technical empowerment guidance for the whole process from project planning to implementation to ensure the smooth implementation of SPCS technology.

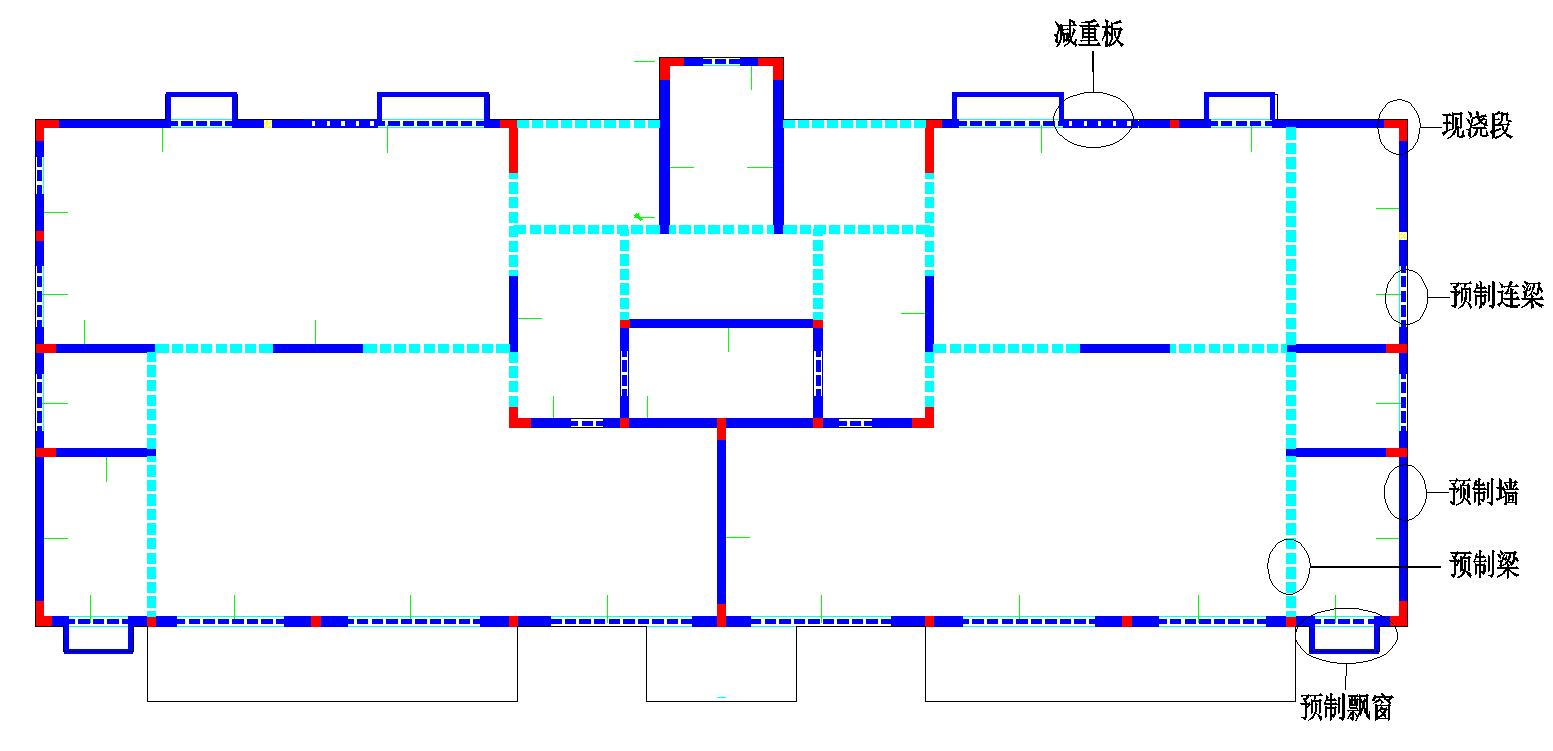

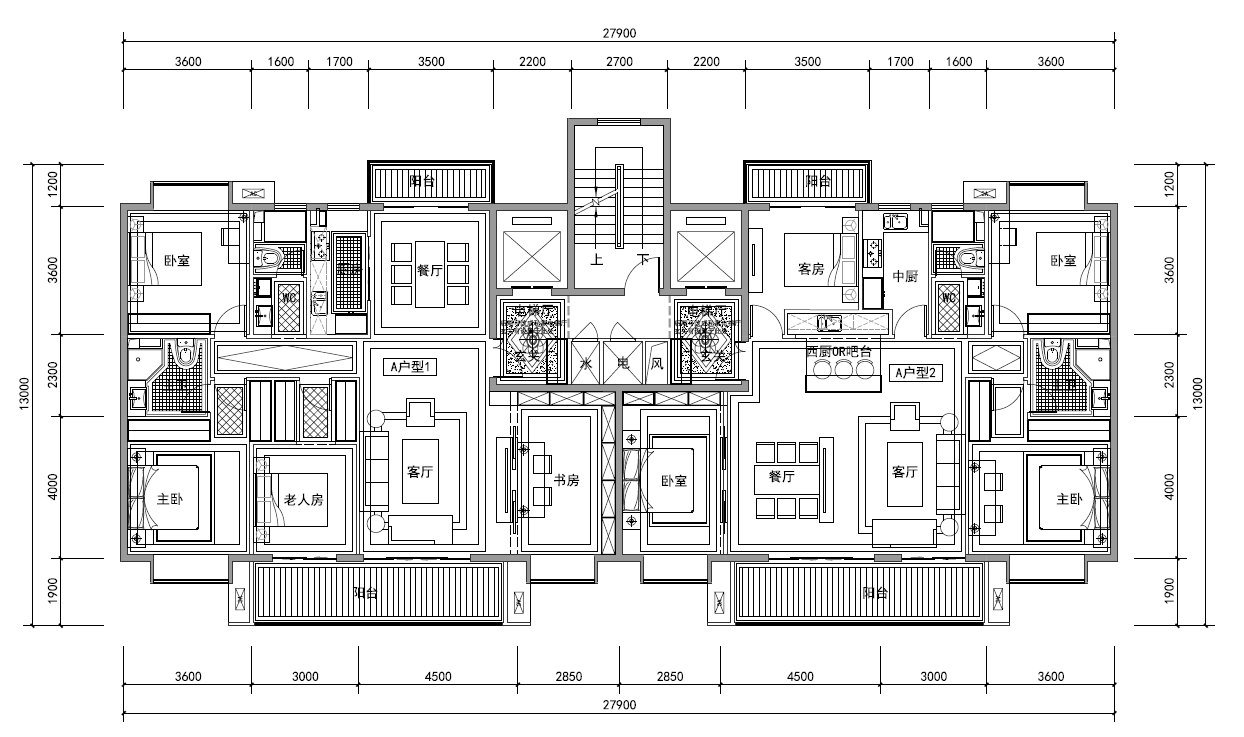

2. The total construction area of this project is 98,489 square meters, of which 18# building adopts Sany Construction SPCS3.0 structural system + SPCH space smart home; The height of the 18# building is 58.45 meters, the floor height is 3.1 meters, and there are a total of 17 floors. The application range of cavity walls is 4-17 floors, and the application range of prefabricated floor slabs is 3-17 floors, with an assembly rate of 66.7%.

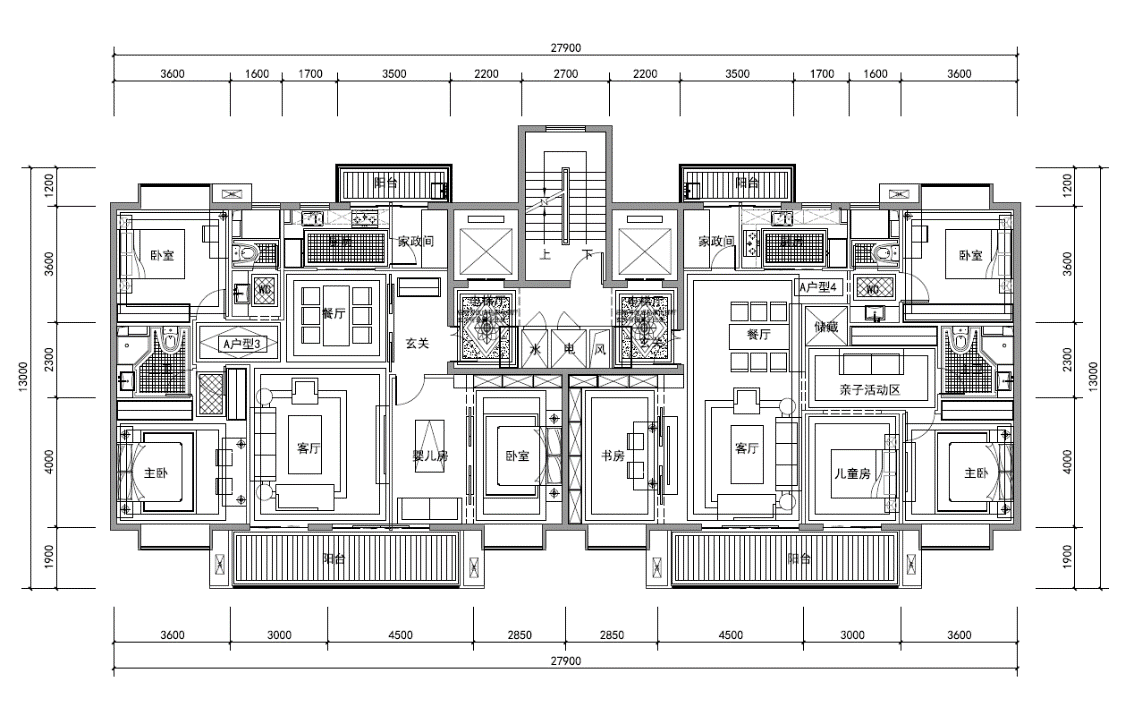

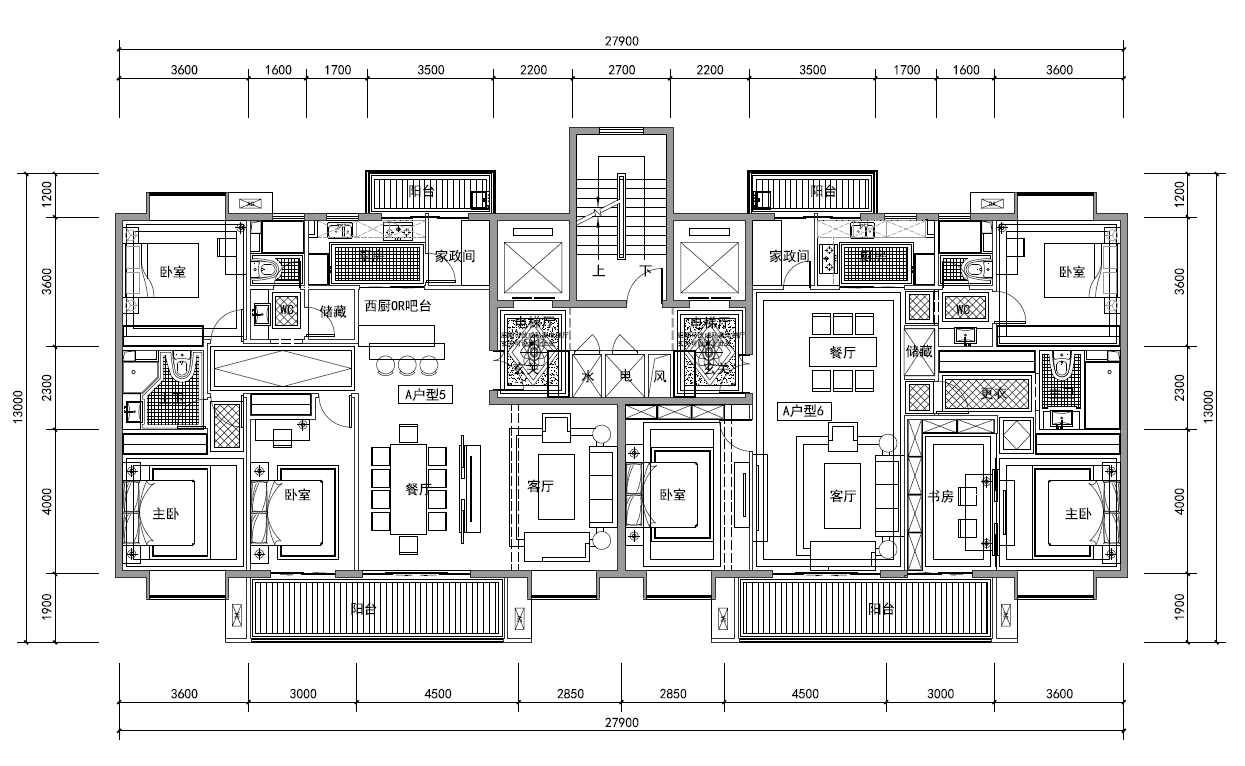

The structural design of SPCH variable space houses needs to create a minimalist structural space, so as to provide basic conditions for the flexibility of the building space, and the shear walls and beams are arranged along the perimeter of the structure when the structure is arranged. A beam is kept in the room that does not affect the adjustment of the building space. The window walls of some building facades are filled with infill walls, which further provides potential for flexible spaces. Future users may also create more variation.

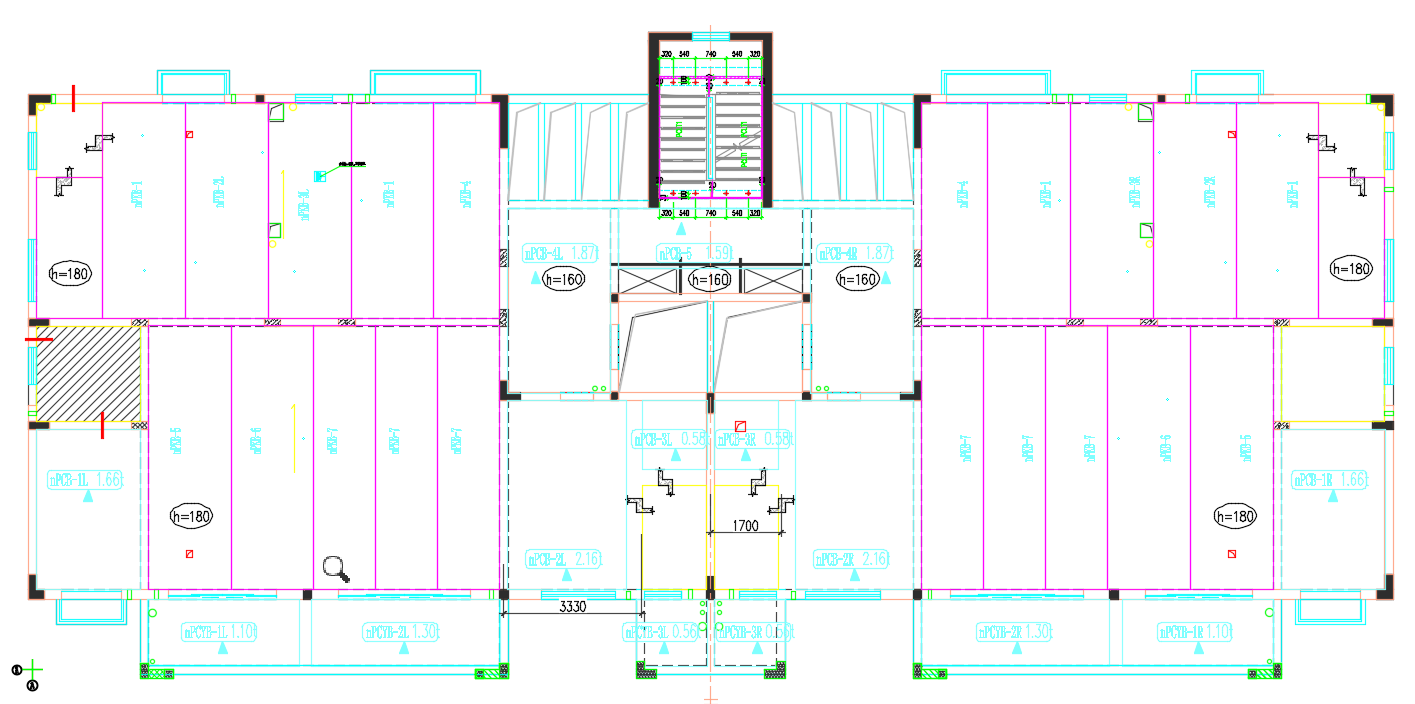

The floor span of this project is 9.6m, which can no longer be realized in the conventional floor form, and a large span floor slab needs to be used. Compared with ordinary reinforced concrete floor slabs, long-span floor slabs have their own characteristics, such as being relatively sensitive to load, accounting for a large proportion of their own weight in their bearing capacity, and the normal use limit state may exceed the bearing capacity limit state to become a control factor. Considering the advantages and disadvantages of building industrialization, construction period, and plate type, the prestressed concrete steel pipe truss laminated board (PK-III plate) was finally used as the horizontal component.

2. The application of SPCS technology system in the project

1. Better: good structural safety, good building quality, and environmental friendliness

The shear wall of the SPCS structural system of 18# adopts "cavity prefabricated components + lap rebar + post-poured superimposed concrete", "cavity + lap + post-pouring" is a "industrial cast-in-place" process, which not only retains the traditional cast-in-place practice, overall safety, good waterproof performance, high quality, but also uses industrial production to improve production efficiency and greatly reduce environmental pollution.

2. More economical: save labor, save construction period, and save construction and safety costs

The 18# building adopts the SPCS system to realize large walls and slabs, which greatly reduces the work content of component hoisting, support erection, formwork installation, steel bar binding, concrete pouring, etc., and reduces the demand for on-site workers. It effectively shortens the construction period of the standard floor, thereby effectively saving construction costs.

3. Advantages of SPCS structure system:

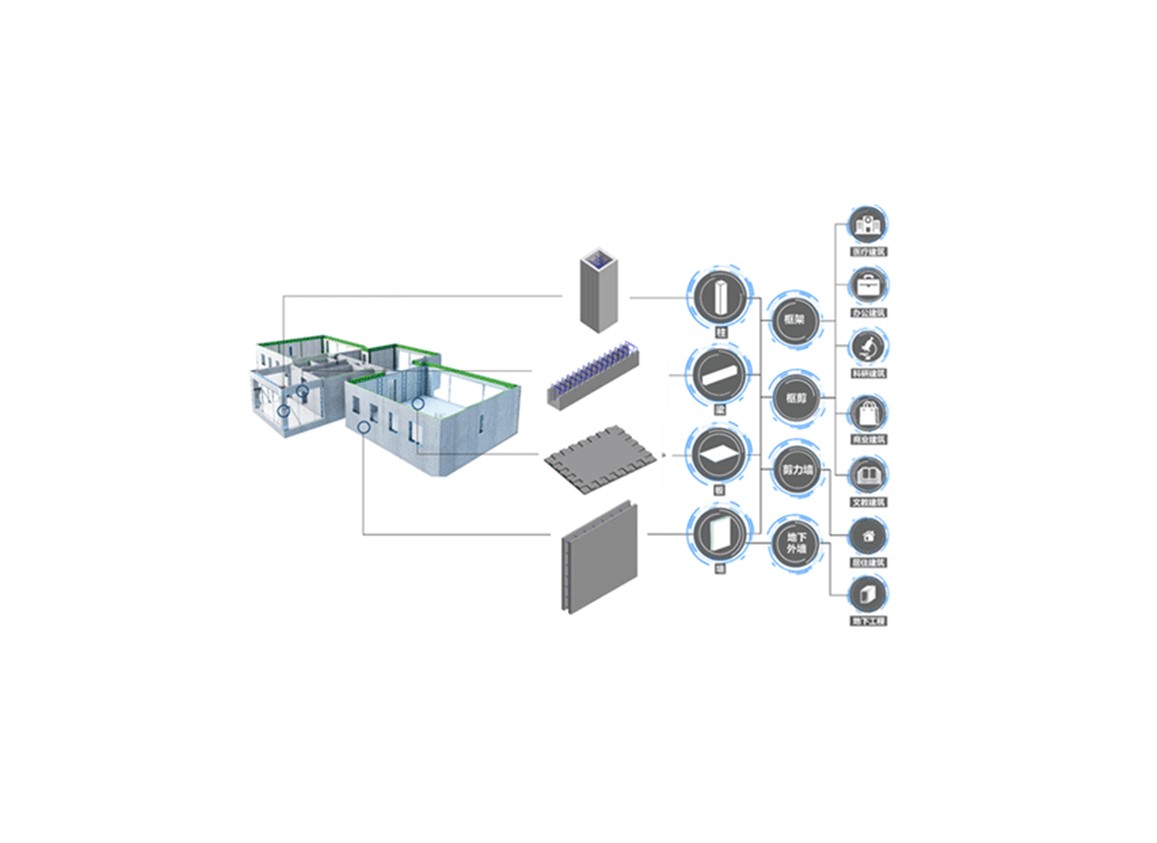

1. The SPCS structural system integrates prefabricated cavity columns, walls, laminated panels, and PK-III plates, and compared with the traditional combination of solid prefabricated columns, walls and laminated floor slabs, the main stressed components have lighter weight, which is convenient for transportation and hoisting, and has lower requirements for tower cranes and other lifting equipment.

2. The connection method is more effective: the common assembly of integral concrete structure vertical components, using grouting sleeve connection method, this method is difficult to ensure the grouting quality and can not be detected later, while SPCS assembly monolithic concrete superimposed structure components are mechanically connected or indirectly lapped with steel bar sleeves, without embedded sleeves, which can effectively solve the quality hazards of grouting sleeve connections, so as to ensure the construction quality.

4. SPCH space smart home

Space Agility Home is an industrial building product of "large space", "smart" and "moving".

"Large space": the main structure is minimalist, the outline is as simple and square as possible, the load-bearing walls and structural columns in the house are completely eliminated, and all vertical load-bearing structures are arranged along the periphery, mainly oriented towards the maximum openness and transparency, and the large indoor space has no columns, which provides basic conditions for meeting the customized variable space needs of residents.

"Ling": smart home and building intelligence, using industrialized intelligent manufacturing technology and platform advantages, promoting the research and development of modular and intelligent integrated wall systems in stages, and improving the industrialization and intelligence of interior components and internal partition walls. By integrating the latest scientific and technological achievements and products of building industrialization, we can achieve higher housing quality with industrial production methods to the greatest extent. Smart home has begun to change people's living patterns, combining building parts, interior furniture and artificial intelligence, buildings will understand themselves better than us, can learn people's behavior through memory, and intelligently meet all the needs of people's living, office, entertainment, social interaction, etc.

"Moving": Through the partition wall system that can be "moved", the flexible house design with menus, the complete technical system, and the factory-customized parts, it brings residents a comprehensive choice of functional layout, material quality, life mode and consumption mode. The interior adopts a modular smart partition wall system that can be assembled, combined with the application of variable furniture, to realize the change of the number, size and function of the room, freely divide the space, and freely switch the family scene.

Building 18# of Loudi Sanyi Block adopts standardized components with fewer specifications and multiple combinations, and provides different variable space combination schemes to meet the living needs of different residents according to the characteristics of the family life cycle (Figure A-Figure C):

It can realize a two-person world that meets the social needs of young couples; provide "entrepreneurs" for entrepreneurs and home office in the post-epidemic era; It provides a variety of apartment types for households with different family life cycles, such as families of three, two-child families, and three generations living together.

Multiple options

The successful capping of 18# in Loudi Sanyi Block is a milestone and important node, which marks a major breakthrough in the technical system combining SPCS 3.0 and SPCH. Sany Construction has promoted the low-carbon development, transformation and upgrading of China's construction industry, promoted China's construction industry to a new era of intelligent construction development, and promoted China's construction industry to make great strides in the direction of "better, faster and more economical".

SPCS structure system

Structural standardsRecommended products

Related recommendations

Jiajia's new mechanical boyfriend - Sany Mobile Cone Crushing Station!

2025.08.08

The national standard GB/T 45972-2025 "Technical Requirements for the Production of Complete Sets of Equipment for the Production of Concrete Plates for Prefabricated Buildings" prepared by Sany Construction was officially approved and released by the National Standardization Administration on August 1, 2025, and will be implemented on February 1, 2026.

2025.08.05

【Jiajia Broken Thoughts】Anti-involution alliance Jiajia will show you how Sany Mobile counterattack crushing station violently hits industry barriers!

2025.07.23

0 comments