What is Sany Renewable Energy's "Super Factory"?

2023.03.28

Sany Renewable Energy

What kind of factory can receive such high praise from two industry leaders? Why is Sany Renewable Energy's Shaoshan blade factory called a "super factory"? How exactly does it compare to a traditional factory? What does the products produced by the "gigafactory" mean to the customer? Today, let's solve the mystery one by one.

Sany Renewable Energy Super Blade Factory is located in Shaoshan, Hunan Province, covering an area of more than 500 acres, with the largest single wind turbine blade production workshop in Asia, with a production line length of nearly 600 meters, which can accommodate 12 sets of molds for simultaneous production, and can produce 3,000 wind turbine blades per year. However, "big" is not the only advantage of this factory, and the biggest difference between it and traditional blade factories is its "four supers".

Sany Renewable Energy Super Blade Factory is located in Shaoshan, Hunan Province, covering an area of more than 500 acres, with the largest single wind turbine blade production workshop in Asia, with a production line length of nearly 600 meters, which can accommodate 12 sets of molds for simultaneous production, and can produce 3,000 wind turbine blades per year. However, "big" is not the only advantage of this factory, and the biggest difference between it and traditional blade factories is its "four supers".

Super digital intelligence

One of the most striking features of this "super factory" is super digital intelligence. In the production of traditional wind turbine blades, work distribution and process control mainly rely on on-site human coordination or technical drawings; Material distribution mainly relies on manual pushing of material carts to distribute, which is not efficient and prone to errors; The factory is full of people, materials are piled up, and workers are busy repeatedly and tiringly..... Even so, there are still industry problems such as difficult management, large fluctuations in quality, and low production efficiency.

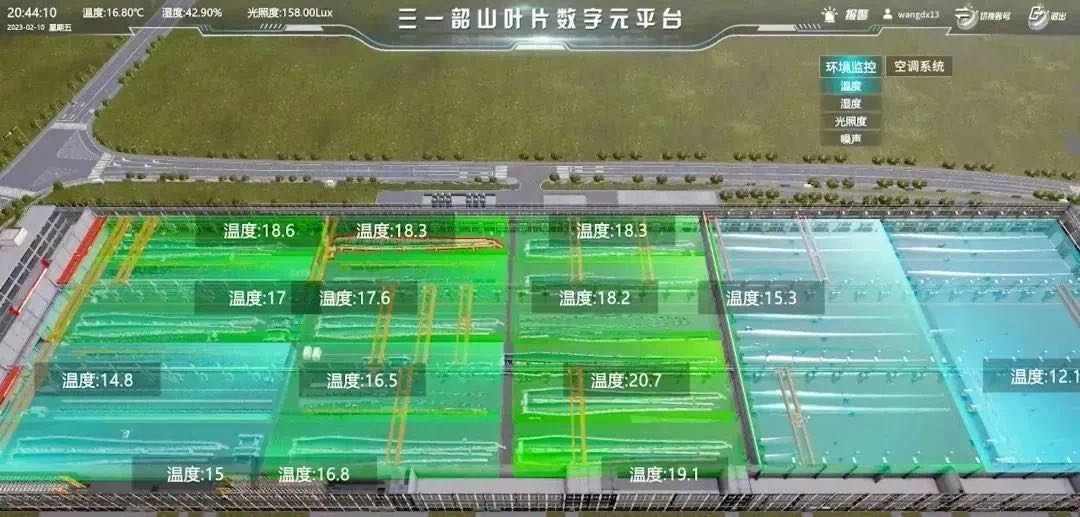

The super factory has realized the digital intelligence of the factory through the "digital meta platform" independently developed by Sany Renewable Energy. Through the combination of digital twin technology, human-machine interconnection technology, automation technology and 5G communication technology, the platform has independently developed a "meta-platform" control system, so that the production process, process parameters and technical indicators of the entire blade are all presented on the meta-platform through digital means, and managers can monitor all important production indicators in the factory in real time through a tablet computer, which greatly improves the management efficiency and operational accuracy of the factory.

The super factory has realized the digital intelligence of the factory through the "digital meta platform" independently developed by Sany Renewable Energy. Through the combination of digital twin technology, human-machine interconnection technology, automation technology and 5G communication technology, the platform has independently developed a "meta-platform" control system, so that the production process, process parameters and technical indicators of the entire blade are all presented on the meta-platform through digital means, and managers can monitor all important production indicators in the factory in real time through a tablet computer, which greatly improves the management efficiency and operational accuracy of the factory.

Temperature and humidity control from each production unit in the factory; torque control to each bolt screw; Process details from resin centralized infusion; From the smoothness coefficient of the grinding of the end face of the blade root, each key indicator that ultimately affects the quality of the product can be monitored in real time on the meta-platform, and problems can be found in time. It can be said that Sany Renewable Energy's original "digital element platform" control system has raised the level of product quality control to an unprecedented height.

Hyper-automated

The second distinguishing feature of the "gigafactory" is hyperautomation. The production of wind turbine blades has always been considered a labor-intensive industry. In the past, blade production required a large number of manual processes such as laying, pouring, grinding, and painting, which not only had low production efficiency, but also had differences in production processes.

The super factory uses AGV+ robot with laser guidance or visual camera guidance to realize the end effector to complete assembly, grinding or spraying and other operations: the equipment can automatically adjust the posture, automatically identify the shape of the blade, and copy the operation; The omnidirectional motion AGV composite robot cooperates with lidar to realize automatic obstacle avoidance during operation, safe and efficient operation. This also increases the automation rate of the gigafactory by 50% and the quality of the product by 30%.

Take leaf perfusion, for example. Different from the traditional manual perfusion one by one, the Shaoshan blade "super factory" adopts the industry's first set of large-scale centralized perfusion technology, which can realize a high degree of automation in the whole process of resin material import, storage and use, making the leaf perfusion as convenient and accurate as a car going to a gas station to refuel. The resin is incoming by tanker, stored in tanks, transported by pipeline, degassed centrally, mixed at the edge of the line, and poured online. The perfusion efficiency of a single blade can be increased by 25%, which can effectively improve the perfusion quality and reduce the labor intensity of employees.

Super lean

Efficiency is required from digital intelligence and automation, and quality is required from lean. The wind turbine blade forming process is a process-based process and is irreversible. If there is a small process deviation or quality defect, it will cause the scrap and loss of the entire blade. Shaoshan Blade Super Factory uses advanced technology to achieve lean production.

Take the layup process as an example. The super factory adopts the industry's advanced programmable laser projection technology to realize the projection of the wire bundle on the surface of the mold, and realizes the intelligent auxiliary positioning of key processes such as layup and main beam positioning through visual laser projection. The use of laser rays instead of manual marking and measurement greatly reduces the labor intensity of personnel, and the positioning accuracy of key dimensions is increased from ±10mm to ±5mm.

Super low-carbon

Another feature of the Gigafactory is that it is super decarbonized. The super factory has built a clean energy system of wind power, photovoltaic and energy storage in the park, built a microgrid digital twin platform, and realized the virtual and real linkage and real-time twin of the photovoltaic power station by collecting data such as the operation status, system, environment and power of the power station, and realized the in-depth data application of equipment status diagnosis, abnormal alarm reminder, and power generation prediction based on digital technology. It solves 66% of the production and living electricity consumption of the park, laying the energy foundation for the construction of a zero-carbon park and cost control.

Quality changes the world, and intelligent manufacturing creates the future. Shaoshan Blade Super Factory has achieved super innovation in terms of "people (workers), machines (equipment), materials (raw materials), methods (processes), and environment (environmental protection)", which has increased the work efficiency of workers by 20% compared with traditional factories; Large-area robot equipment replaces manual work; Realize automatic material distribution and finished product transfer; The efficient production process shortens the average construction period of a single 100-meter-level blade from more than 40 hours to about 30 hours, which will greatly meet the supply needs of customers.

Sany Renewable Energy, leading the future of the industry with intelligent manufacturing!

Rail-mounted container gantry crane automation

Rail-mounted container gantry craneRecommended products

automation

Rail-mounted container gantry crane automationNext article:Breakthrough of Zero | Sany was officially launched: China's first electrified highway test line

Related testimonials

Sany Renewable Energy's first offshore engine "big on small" project was officially launched

2025.06.30

Xibei Power and Sany Renewable Energy have cooperated strategically to jointly promote the application of sodium battery energy storage

2025.06.29

Golden Bull Award +1, Sany Renewable Energy was recognized by the capital market again

2025.06.29

0 comments