Service "Xiaobai" growth note: diligent study to build a tower, thick accumulation and thin hair

2023.07.17

Sany crane

In 2019, Li Shun came to Sany Jiangsu Overhaul Factory. In order to let him get started quickly when he first arrived, the factory arranged senior masters to guide him, impart work experience and pay close attention to his growth dynamics. Li Shun is very studious, and if he doesn't understand something, he chases after the master and asks. Because of his strong learning ability and hard work, he quickly grew from a trainee service engineer to an intermediate service engineer. Later, he was assigned to Changzhou, Jiangsu Province, and was responsible for regional service work.

Different from the life of the overhaul factory, there is no fixed working hours and work content on the front line, and Li Shun is often in a hurry to go to the call point while communicating with customers, and he is overwhelmed. He said: "There are all kinds of problems in the service line, and I am often busy until late at night. In this way, he stepped out of his comfort zone step by step, groped his way out, and was able to solve the urgent needs of customers in a timely and fast manner.

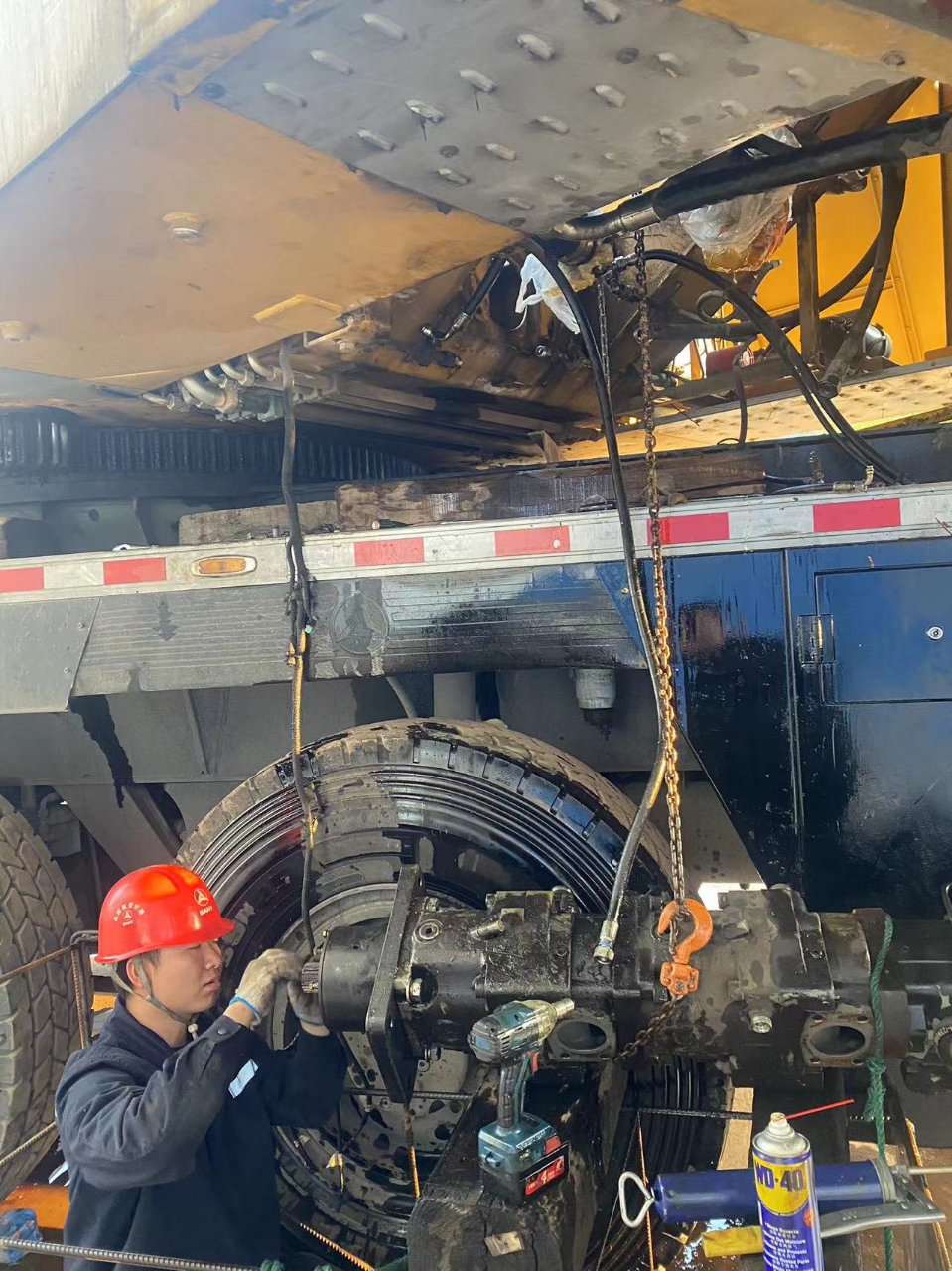

At the beginning of this year, a 100-ton equipment in Changzhou broke down due to too long use, and the power was cut off on the car and there was no action. After receiving the call, Li Shun arrived at the scene on the same day, and found that the conductive ring was damaged, so he quickly replaced the conductive ring. However, during debugging, he found that the equipment was shaking when it was lifted. So, he climbed onto the turntable for further investigation.

According to past experience, he disassembled the transmission shaft and the oil pump, shook the oil pump, and found that the front end clearance was too large, which had exceeded the normal range, so the transmission shaft shook violently during the operation of the equipment, thus breaking the conductive ring. He urgently contacted the spare parts center, informed the model of the oil pump, and waited for the spare parts. At the same time, he carefully explained the situation to the customer and made all the arrangements before returning with peace of mind. When I looked at the time, it was already past 1 o'clock in the morning.

Disassembling and assembling the oil pump is a hard work, and Li Shun coordinated another service engineer, Jin Kaihua, to help. The oil pump weighs 50kg, and the turntable space is limited, only enough for one person to go up, and Li Shun can only move on it in small increments. During the disassembly, the hydraulic oil mixed with sweat seeped into his eyes under the sun, and he couldn't open his eyes several times. The two worked carefully and cooperated with each other to complete the dismantling and reinstallation in one day. After debugging, it is confirmed that the equipment is back to normal and the fault is completely removed.

From the initial service "Xiaobai" to the current service expert who can take charge of himself, four years have passed, Li Shun is no longer anxious in the face of equipment failure, but calm and steady.

After the service was completed, Li Shun returned to the car, picked up the guitar and fiddled with it, he said: "Although I can't play, I just feel that I have to do something to express my happy mood at this moment." He plucked the strings, his eyes shining, and he looked at him that he had just repairedcrane, happily humming the main theme of his own growth.

0 comments