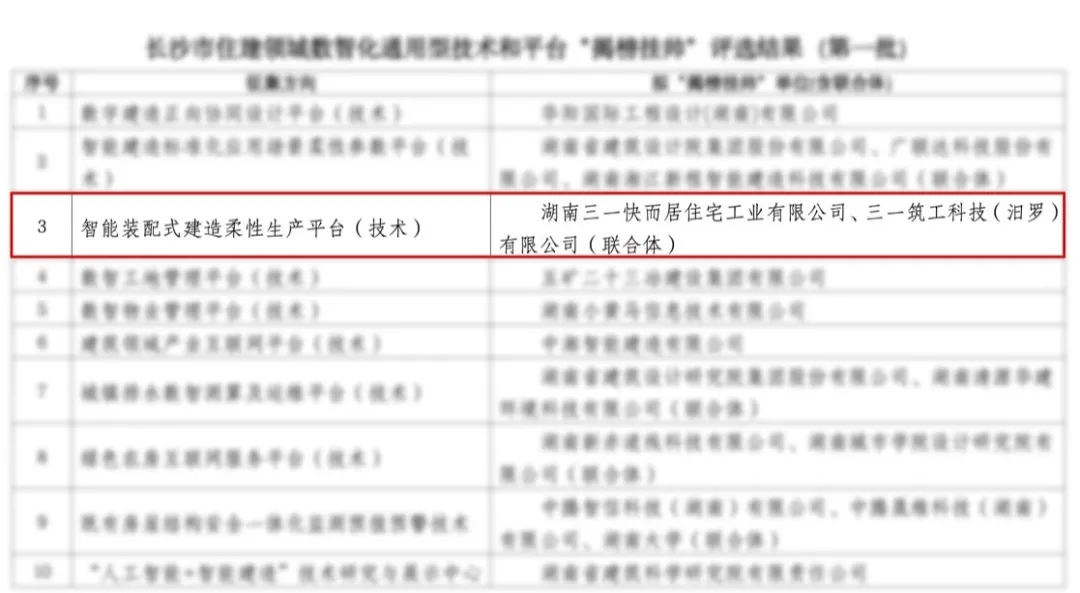

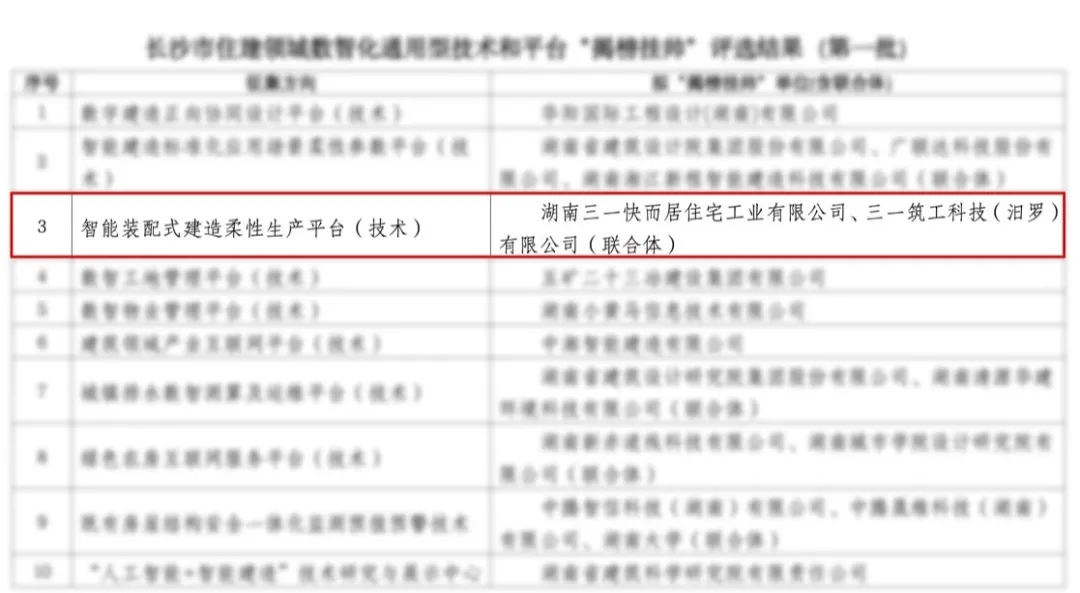

Recently, the results of the selection of digital and intelligent general-purpose technologies and platforms in the field of housing and construction in Changsha (the first batch) were officially announced.Trinity BuildersWith its innovative technology and wide application in the field of prefabricated buildings, the "Modern Flexible Intelligent Production Platform" has been successfully selected and has become an important engine to promote the "digital transformation and intelligent transformation" of the construction industry.

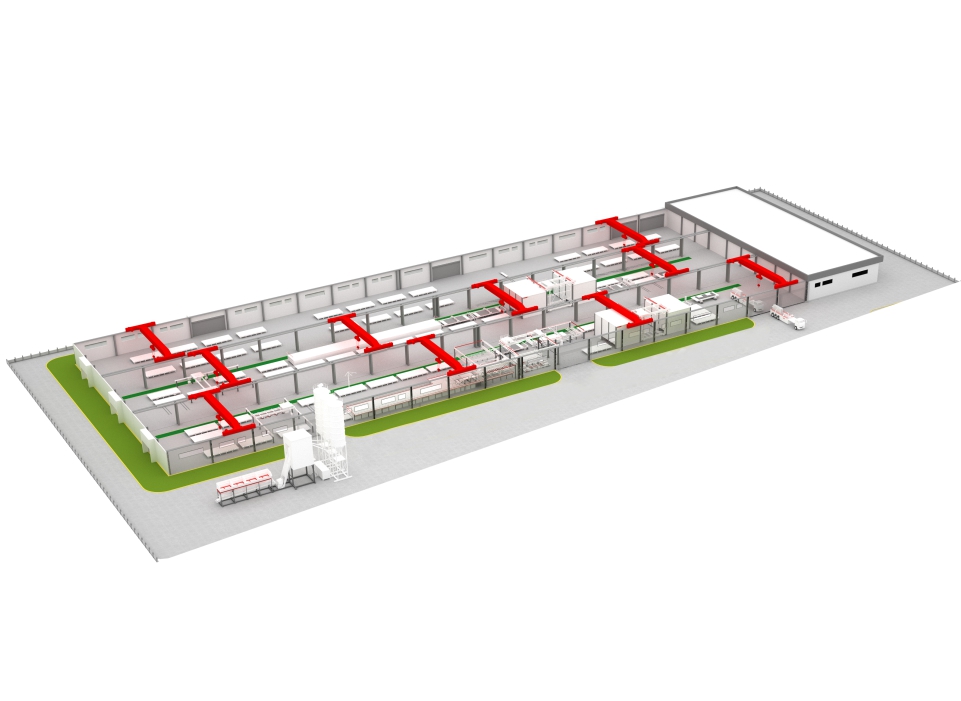

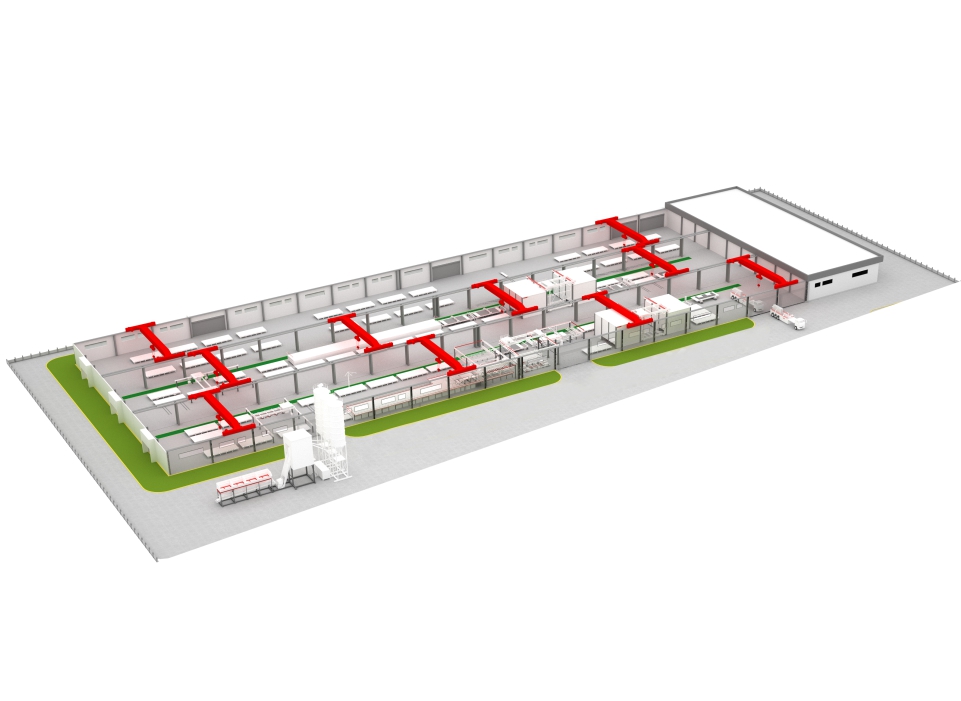

Relying on the advantages of Sany "Global Construction Machinery Three Strong" and the Industrial Internet of Things, Sany Construction has successfully created Sany Construction Industrialization Solution SPCS "3+1", that is, "three hard technologies (design intelligence, manufacturing intelligence, construction intelligence) + construction cloud platform". As an important part of SPCS "3+1", Sany Construction has launched the world's leading modern flexible intelligent production platform (Sany Intelligent PC Production Line), which can automatically analyze 3D models by industrial software and drive the unmanned/less manned production of intelligent equipment by data.

With SPCS "3+1" as the core, Sany Construction has built the world's leading modern flexible intelligent production platform and reshaped the future of architecture with the power of science and technology. In 2024, the domestic open market share will exceed 80%, ranking first in the domestic market share industry for ten consecutive years. In recent years, Sany PC advanced manufacturing technology has been selected into the innovative application scenarios of intelligent construction in Beijing and the list of new practical technologies in the field of intelligent construction released by Changsha, and Sany Construction has won the national intellectual property advantage enterprise.

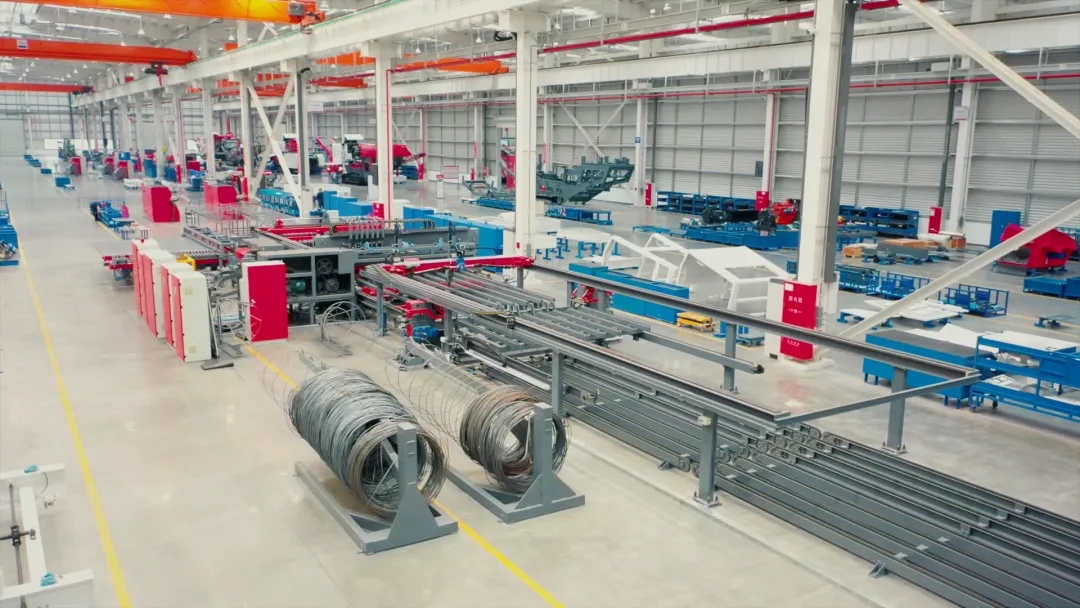

The core equipment of Sany PC production line

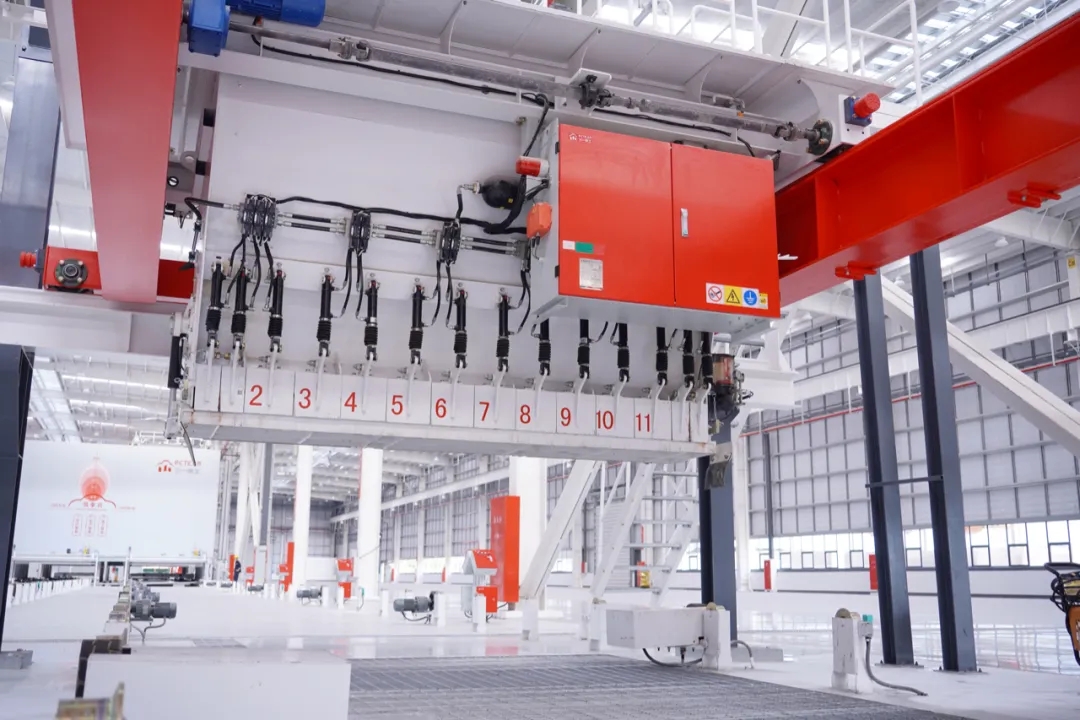

1. Dismantling the cloth mold robot

The uncloth mold robot can data-drive 3D scanning to identify the 3D status of edge molds and magnetic nails, with a recognition rate of more than 99%, exceeding the industry average. Nail pulling and edge die recovery are automatically completed by robots, with multi-functional conveying and cleaning equipment, and AI algorithms provide optimal side mold splicing combinations to realize the layout mold operation of different components. The accuracy of the cloth mold can reach ±1mm, and this equipment is the only PC manufacturing robot applied in batches in China, reaching the international advanced level.

2. Intelligent oiling and scribing machine

The intelligent oiling and scribing machine is driven by BIM data, realizes automatic oiling and scribing, eliminates the process of workers' drawing, the scribing accuracy reaches ±1mm, and the scribing efficiency is 4-6min/die table, which greatly improves the production quality of components.

3. PC steel bar parts production complete sets of equipment

Sany intelligent steel bar production line breaks through the two major industry problems of flexible cage closure and bending of mesh, infinitely adjustable horizontal and longitudinal bar spacing, increasing equipment production capacity by 70%, reducing energy consumption by 30%, and saving raw materials of about 30 yuan/square meter for customers. The self-developed mesh truss assembly welding system realizes the infinitely adjustable truss pitch of 190-210mm, and is compatible with the intelligent production of laminated plywood and floor bearing board trusses. With the self-developed grabbing and delivery manipulator, the whole process of automatic production of steel bar parts from production, storage, grabbing and delivery can be realized.

4. Visual identification quality inspection

The visual recognition quality inspection system integrates AI algorithms, 3D visual scanning and other technologies, which can realize intelligent quality inspection of superimposed floor slabs and SPCS wall panels, and can accurately inspect the contour size, embedded position and size of components, the position and size of steel truss and steel mesh with an accuracy of ±2mm, and the quality inspection efficiency is 2-3min/mold table, which fills the gap in intelligent quality inspection in the industry.

5. Smart fabricSany intelligent fabric system provides the industry's richest solutions such as BIM design drawing drive, vision drive and vision drive. Through data analysis, the supporting fabric center integrates concrete pouring, fabric, vibration and mold table scheduling functions to realize one-click intelligent distribution of concrete, and the standard fabric cycle time is 6min.

6. Flip the mold

Sany intelligent turning machine realizes one-stop scheduling of dry and wet components, and automatic flipping and closing of cavity components. The equipment is designed with high-precision benchmarks, data-driven intelligent online scheduling, and multiple positioning strategies are adopted, with a clamping accuracy of 5mm and high production efficiency.

7. Stacking maintenance

Intelligent stacking and maintenance equipment is divided into stacking equipment and maintenance equipment. The stacking equipment adopts a gripping mechanism and servo control system, which can quickly and accurately send components into the curing kiln, and the production cycle time can be shortened to less than 6 minutes, which is 25% higher than the industry average, greatly improving the production line production capacity. The corresponding position of the maintenance equipment can be automatically opened and closed for maintenance, precise control of maintenance temperature and humidity, online display of maintenance status, good maintenance quality, high efficiency, and low energy consumption.

Represented by the "modern flexible intelligent production platform", Sany Construction is reconstructing the operation mode of PC factories with digital thinking and Industry 4.0 path, and providing customers with a full set of solutions for customized, high-return, digital and fast delivery of prefabricated components. In the future, Sany Construction will continue to deepen intelligent construction, and empower the industry with Sany Construction Industrialization Solution SPCS "3+1", that is, through the "three hard technologies (design intelligence, manufacturing intelligence, construction intelligence) + construction and cloud platform", to achieve "structural safety, cost, green wisdom, good speed, and savings" for popular buildings.

0 comments