21st Century Business Herald: Expand the whole industry chain Sany pioneers the trillion-level prefabricated building market

2016.10.28

After testing the water for many years, Sany Group's strategy in the prefabricated building industry has gradually become clear.

"At present, our market share in the field of prefabricated building equipment has reached 40%." In an interview with the 21st Century Business Herald reporter a few days ago, Zhao Shuai, assistant to the president of Sany Group, revealed that the prefabricated building industry has been listed as one of the new industries developed by the group in the strategic planning of Sany Group, "and our plan in the future is to make it a business sector of 100 billion yuan."

Focusing on this plan, Sany Group has formed a four-layer cascade industrial development path, that is, taking the equipment of prefabricated buildings as the entry point, then progressing to the PC (prefabricated concrete parts) production solution provider, and then expanding to the EPPCM (design, procurement, production, construction, information management) field. In addition, Sany Group also plans to use its land reserve in the country, through the demonstration effect of real estate development projects, in order to open up the whole industrial chain of prefabricated buildings, "we are currently hoping to form a demonstration project as soon as possible, connect all the chains, and form a demonstration effect of the entire industry."

However, at present, in China, the proportion of prefabricated buildings in China's construction industry is still very low, the market acceptance of it is not high enough, and there are still problems such as interest games between it and the traditional construction industry, "but the advantages of prefabricated buildings are obvious", Zhao Shuai said that in the next few years, with the support of national policies, the industrial scale of prefabricated buildings will expand rapidly, and whoever can seize the opportunity will be able to stand firm in the market in this field.

Advantages of energy saving and environmental protection

Before prefabricated buildings were widely used, residential industrialization was more used to refer to this industry in China.

The advantages of building industrialization are: stable and controllable product quality, accurate and controllable cost, high construction efficiency, energy saving and environmental protection.Trinity ConstructionAccording to the information provided, compared with the traditional construction industry, building industrialization can save 80% of water, 70% of energy, 70% of time, and 20% of materials. This theoretical advantage allows the state to accelerate policy support. In 2016, the "Several Opinions of the Central Committee of the Communist Party of China and the State Council on Further Strengthening the Management of Urban Planning and Construction" proposed that it would take about 10 years to make the proportion of prefabricated buildings in new buildings reach 30%. In this context, the industrialization of construction represented by China's prefabricated buildings is regarded as representing an emerging market.

"At present, prefabricated buildings account for only about 2% of the scale of China's construction industry. In 2015, the output value of China's construction industry was 18 trillion yuan. An industry source estimates that if the goals of the national plan are promoted, the future scale of this industry will grow by at least 10 trillion yuan. Optimistic about this market, Sany Group has long been preparing to enter this field. According to the company, Sany Construction Technology Co., Ltd. (hereinafter referred to as "Sany Construction") is one of the operating entities of Sany Group in the prefabricated building industry. As early as 2007, Sany Group established Shanghai Zhushengyuan Real Estate Company to enter real estate development and try prefabricated building construction. In 2014, Sany acquired Kuaierju and became a domestic *5655 PC complete equipment provider.

"Sany Heavy Industry is a construction machinery enterprise with complete product categories in China." Zhao Shuai introduced that previously, the company's accumulated experience in the field of construction machinery, especially the refined and intelligent manufacturing process, allows the company to provide the most complete set of equipment for the whole industry chain, that is, from the production and transportation of prefabricated parts, to the on-site construction of cranes, auxiliary tooling and the production and transportation of raw materials and concrete used in the production and transportation of equipment and other aspects of Sany has a full range of equipment support. According to the information provided by Sany Group, so far, Sany Construction has built 71 PC production lines in China, accounting for more than 40% of China's PC complete equipment market share, in addition, Sany Construction has 2 PC factory projects under construction abroad.

One of the *5655 problems faced by the traditional construction industry today is the shortage of construction workers, which will be more serious with the rise of the post-90s generation in the future, which also pushes up the labor costs of the traditional construction industry. "This is another reason why the country vigorously promotes prefabricated buildings." The above-mentioned people pointed out that prefabricated buildings can save a lot of labor costs through industrialization, standardization and process.

Bottlenecks in the industry

Despite this, there are still some problems to be overcome in the promotion of prefabricated buildings. "At present, from the industry level, there is still a lack of the ability to promote the prefabricated building industry as a whole, and the explicit cost of prefabricated buildings is still relatively high." The above-mentioned industry insiders said that for example, the construction cost of well-known domestic real estate companies may be about 300 yuan per square meter lower than the cost of prefabricated buildings. In addition, the current development of the prefabricated building industry is not mature enough, so the coordination ability of each link is relatively limited.

"Normally, the time cost of prefabricated buildings will be very low, and a floor can be built in about 10 days through traditional construction, and prefabricated buildings are claimed to be built in 3 days, but in fact, due to process settings, coordination is not in place, etc., resulting in a short construction period for a single link, but the time to wait for other parts to follow-up is longer." The above-mentioned person pointed out that in addition, the prefabricated building is mainly prefabricated parts production, and its requirements for equipment are higher, "in the past, only 30 tons of tower cranes were used, and now 70 tons of tower cranes may be required to operate, and the rental price of equipment is higher, in addition, in this process, although labor is saved, these workers are not familiar with the use of equipment and the process of assembly, and the lack of professionalism in the transportation process, which may lead to the actual loss of prefabricated parts. It's not as good as it seems.

In the traditional construction industry, the whole industry chain of the construction industry involves five links such as design, development, construction, and decoration, and the above-mentioned people pointed out that "these links represent different legal entities and belong to the community of interests of the traditional construction industry, but the emergence of prefabricated buildings may be opened up by an enterprise to open up the whole industry chain, which will bring damage to these existing stakeholders." This is also an obstacle that may be faced in the process of promoting prefabricated buildings. This obstacle is only temporary, though. From the perspective of comprehensive cost, prefabricated buildings are still better than traditional construction methods. Zhao Shuai said that under the current policy requirements for energy conservation and environmental protection in the construction industry, the acceptance of prefabricated buildings by developers is improving.

From the perspective of the cost of the whole process of the industrial chain, the construction cost and construction waste cost of the traditional construction industry are superimposed, and the explicit economic cost of prefabricated buildings is almost the same. However, from the perspective of future trends, the cost of prefabricated buildings will be lower. "The cost of traditional construction will rise in the context of labor shortage, but after the scale effect of the prefabricated building industry is generated, the price of prefabricated parts and other parts will decline, and the efficiency will be rapidly improved. Zhao Shuai said that in the future, with the advancement of construction industrialization, the promotion of lean management and the promotion of industrialization process, its management will produce benefits and provide space for future cost reduction.

For the safety of prefabricated buildings, their quality will be more guaranteed. "Compared with manual walling, machine wall products at least will not appear hollow, cracks and other quality problems, and at the node of prefabricated parts, in accordance with national regulations must also be equivalent to cast-in-situ, with the completion of scale and process combing, the advantages of prefabricated buildings in energy conservation and environmental protection will be more obvious.

Provide integrated solutions

Construction industrialization is a new model formed by the cross-border integration of manufacturing and construction industries. According to incomplete statistics, at present, there are less than 10 large enterprises that have proposed to enter the construction industrialization, including Yuanda, Baoye, Zhongnan Construction, etc., but the participating enterprises are on the rise. "China's prefabricated building industry is basically in its infancy, and the development of these enterprises participating in industry competition still has certain defects." The above-mentioned industry people pointed out that for example, some enterprises use non-industry methods to promote, and some enterprises still lack large-scale effects. However, at present, there is a lack of a leading enterprise in the industry to open up the whole industrial chain of prefabricated buildings, form an industry standard for the whole industrial chain, and standardize the industry.

Sany Group's plan is to provide comprehensive solutions for the whole industry chain for prefabricated buildings. Zhao Shuai pointed out that "Sany Group takes engineering equipment manufacturing as the entry point to open up the industrial chain of prefabricated buildings, and we can provide all the equipment on the whole industrial chain of prefabricated buildings, including parts construction, concrete, earthwork construction and other equipment, and can carry out equipment information interconnection, in addition, Sany Construction Engineering has also been involved in the design of PC production solutions." In addition, the company plans to carry out EPPCM business through the promotion of a complete set of solutions.

From design to production, construction, decoration, to property services after the traditional building, each link is separated. Zhao Shuai said that Sany can string this chain together through lean manufacturing methods and information technology to achieve *5655 optimization of production efficiency. "Sany Group has no experience in construction, but we have the resources and we may also work with third parties, with the ultimate goal of providing integrated solutions for this industry." Zhao Shuai said.

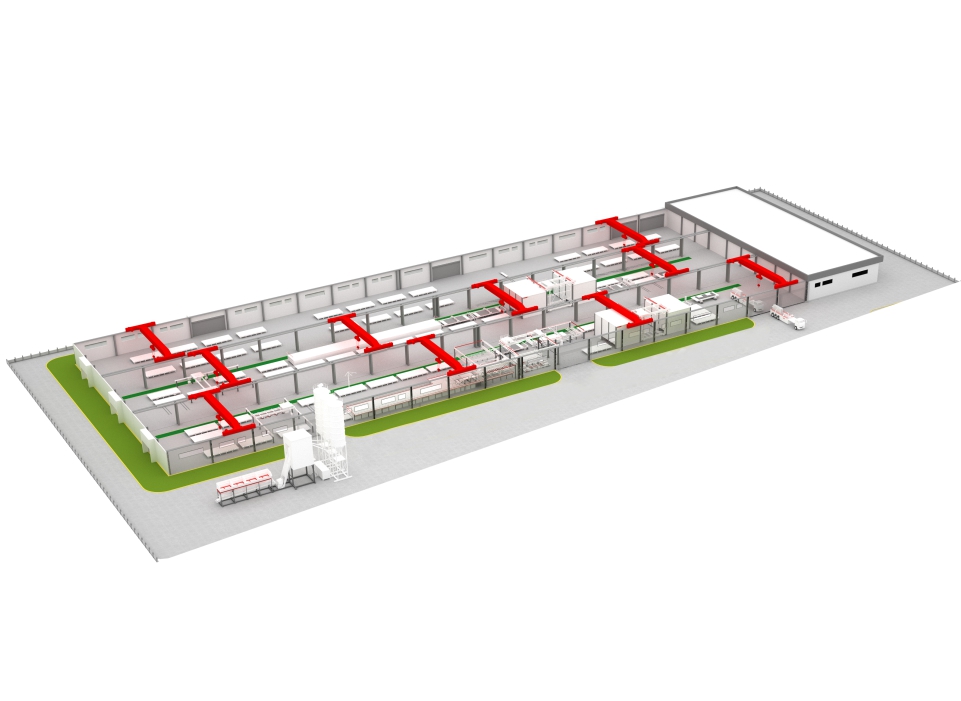

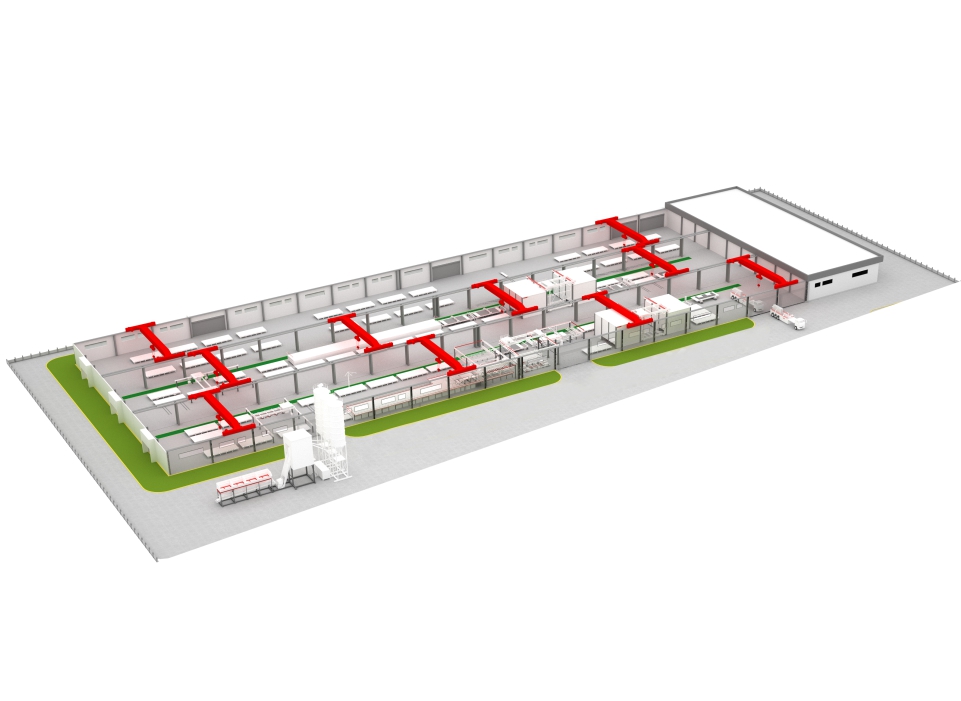

Sany PC integrated automated production line

SPCE smart PC equipmentRecommended products

PC production line

Sany PC integrated automated production lineNext article:Changsha Evening News: "Tomorrow's Home" shows the future concept of prefabricated buildings

Related testimonials

CCTV Finance × Sany Heavy Industry: Infrastructure results are released! Anhui is soaring, and the equipment of the western port has become a "dark horse"

2025.05.19

China's installed wind and solar capacity has historically surpassed that of thermal power

2025.04.28

Breakthroughs have been made in the challenges of customization and high precision, and new progress has been made in the intelligent production of high-end equipment

2025.03.24

0 comments