China Construction News: Leading the Development of Intelligent Construction with Innovation and Boosting the Transformation and Upgrading of the Construction Industry!

2023.07.17

China Construction News

On July 11, China Construction News published a full-page article: "Leading the Development of Intelligent Construction with Innovation and Boosting the Transformation and Upgrading of the Construction Industry - Sany Construction Engineering Innovative Technology Comprehensively Empowers Intelligent Construction". The original text is as follows:

A few days ago, the 20th China International Housing Industry and Construction Industrialization Products and Equipment Expo (hereinafter referred to as the "Housing Expo") was held in Beijing, as a concurrent meeting, the "2023 National Intelligent Construction and Construction Industrialization Collaborative Development Exchange Conference" was held in Beijing Sany Industrial Park, more than 200 people including industry leaders, academicians, experts and entrepreneur representatives attended the on-site meeting, and more than 13,000 people watched online.

As the organizer of the conference, the relevant person in charge of Sany Construction Technology Co., Ltd. (hereinafter referred to as "Sany Construction") delivered a keynote speech on "Thinking and Practice of Intelligent Construction" during the meeting, and held the release ceremony of "Sany Group Intelligent Construction Blueprint" and China Engineering Construction Standardization Association Standard "Construction and Quality Acceptance Regulations for Assembled Integral Laminated Concrete Structures", which received great attention from all walks of life.

The site of the 2023 National Intelligent Construction and Construction Industrialization Collaborative Development Exchange Conference

The site of the press conference of "Sany Group Intelligent Construction Blueprint" and China Engineering Construction Standardization Association Standard "Construction and Quality Acceptance Regulations for Assembled Integral Superimposed Concrete Structures".

Build a digitally empowered industrial system

——From the development trend to the realization path

The conference was hosted by the Science and Technology and Industrialization Development Center of the Ministry of Housing and Urban-Rural Development, co-organized by the Beijing Housing and Urban-Rural Construction Science and Technology Promotion Center, the Housing and Urban-Rural Development Bureau of Qingdao City, Shandong Province, and the People's Government of Nanchang County, Jiangxi Province. During the conference, the guests discussed the development trend of intelligent construction, displayed the achievements of digital technology innovation, and shared the practical experience of building industrialization, so as to help accelerate the coordinated development of intelligent construction and building industrialization.

The guests at the meeting believed that the development of intelligent construction is an important measure in the field of housing and urban-rural construction to deeply study and implement the spirit of the 20th National Congress of the Communist Party of China, and to empower the industrialization, digitalization and green transformation of the construction industry with science and technology, which is conducive to promoting the quality of engineering projects, reducing costs, and building good houses that are satisfactory to the masses.

Xiao Xuwen, academician of the Chinese Academy of Engineering, believes that in the face of the new era, new situation and new tasks, the construction industry must start from the "four modernizations" to achieve high-quality development, that is, green construction is the basic requirement for the construction industry to achieve high-quality development, digital construction and lean construction are effective ways for the construction industry to achieve high-quality development, and international construction is an important way for the construction industry to achieve high-quality development. The transformation and upgrading of the construction industry must take green construction as the goal, and build a new pattern of high-quality development of the construction industry through the deep integration of intelligent construction and lean construction.

Cheng Weihua, deputy general manager of Sany Group and general manager of Sany Construction Engineering, said that the future of popular buildings must be prefabricated buildings, and prefabricated buildings must rely on intelligent construction and building industrialization to develop in a coordinated manner. Ni Hong, Secretary of the Party Leadership Group and Minister of the Ministry of Housing and Urban-Rural Development, pointed out at the China Electric Vehicle 100 Forum that it is necessary to build a house like a car, indicating that the coordinated development of intelligent construction and building industrialization is the direction of high-quality development of the construction industry. Sany Construction Engineering firmly believes that this will become a key factor in promoting the transformation and upgrading of the construction industry and achieving sustainable development.

Fan Zesen, deputy general manager and chief architect of China Construction Technology Group, believes that the upstream of the construction industry is the manufacturing industry, and the rapid development of intelligent manufacturing is that the construction industry must have intelligent tools to undertake the products and building materials of the upstream manufacturing industry, which must be integrated with upstream industrialization and digital tools. The foothold of intelligent construction is to promote industrial transformation, practice green development, implement the high-quality development of the construction industry, build a good house, and meet the people's expectations for a better life at a new historical point in time.

Sun Tianshu, a tenured professor at Cheung Kong Graduate School of Business and a tenured professor at the University of Southern California, said that the future of digital and intelligent transformation of the construction industry is reflected in three aspects: first, intelligence, GPT (generative pre-trained Transformer model) is currently promoting global industrial upgrading; The second is digitalization, which requires a strong top-level design, and digital transformation must complete the positive cycle from business to data and data-driven business, and reshape the construction industry scenario; The third is the evolution of platform, manufacturing + service + community + ecology, so that enterprises gradually become digital enterprises.

Wang Kecheng, Secretary of the Party Committee and President of Guangdong Bozhilin Robot Co., Ltd., believes that construction robots will bring changes to the construction industry from five aspects: safety, efficiency, quality, energy conservation and emission reduction and employment. The application of robots can not only change the status quo of digitalization and low automation in the construction industry, but also play an active role in driving young people's employment.

Liu Changchun, deputy general manager of science and technology of Suzhou Kelida Decoration Co., Ltd., and Zhou Dongshan, deputy general manager of Zhejiang Yasha Decoration Co., Ltd., proved with actual engineering project cases that the application prospect of intelligent construction in prefabricated decoration is very broad.

On the path of intelligent construction, the guests reached a consensus: to realize intelligent construction, promote the deep integration of digitalization, industrialization and intelligence in the field of engineering construction, which is the only way for the transformation and upgrading of the construction industry

Xiao Xuwen believes that digital construction has brought about "four changes" in the form of the construction industry: from the logic of zero-sum competition to the ecological logic of synergy and symbiosis; From inefficient, high-strength, high-risk, and high-precision positions, job substitution, job upgrading, and new jobs appear; From design institute + construction unit + whole-process consulting to a service provider integrating digital construction and physical construction; Shift from a multi-level organizational structure to a flat organizational structure. The "four transformations" determine that all participants in digital construction must work together on the same platform to achieve efficient collaboration, create a digital twin system, first "virtual construction", and then complete "physical construction". Digital construction should pay attention to practical results, first, accelerate the reform of the project management system and mechanism, and vigorously develop the general contracting of projects; the second is to create an underlying computer support and graphics system with independent intellectual property rights; The third is to accelerate the creation of a systematic working platform (EIM platform) for real-time control and operation of information flow, material flow, capital flow and various resources of intelligent construction of engineering projects; the fourth is to accelerate the development and application of robots; Fifth, attach great importance to digital construction; Sixth, pay attention to top-level design.

Cheng Weihua said that the development of intelligent construction should "learn from the manufacturing industry", and the future of intelligent manufacturing is today. Song Xiaogang, executive chairman and secretary general of the China Robot Industry Alliance, highly agreed with Cheng Weihua's views and said that whether it is intelligent construction or building industrialization, robots are the core intelligent equipment. At present, China's industrial robot industry has initially formed a relatively complete industrial chain of ontology, parts and integrated applications, but compared with the international advanced level, there are obvious shortcomings, weaknesses and "stuck neck" risks, China's industrial robots are in the low-end in the global market competition, collaborative innovation is an important measure to accelerate the high-quality development of the robot industry.

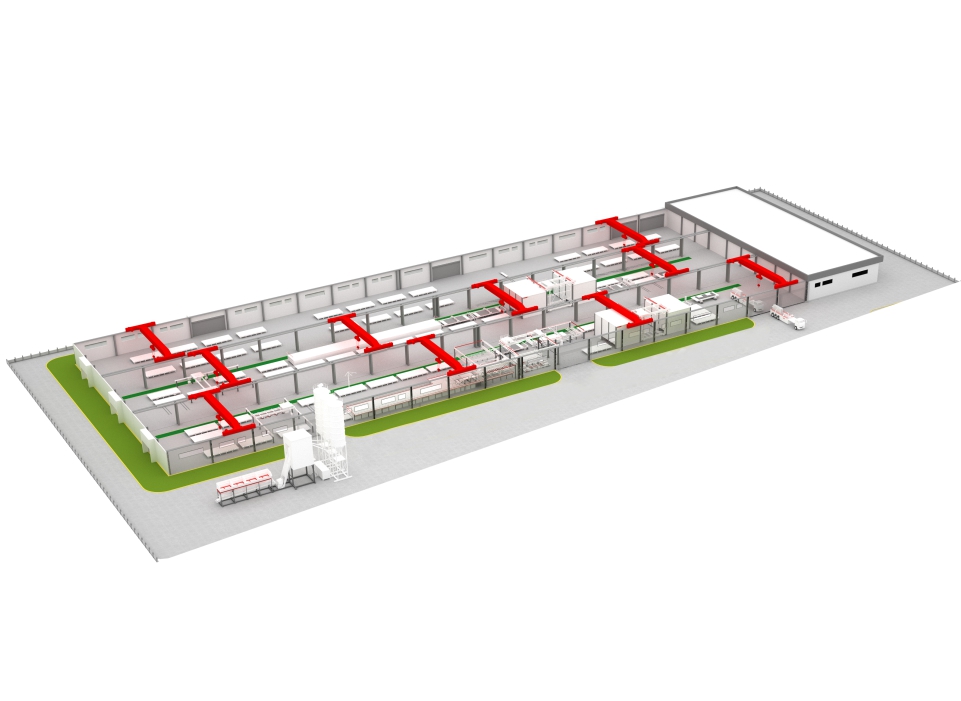

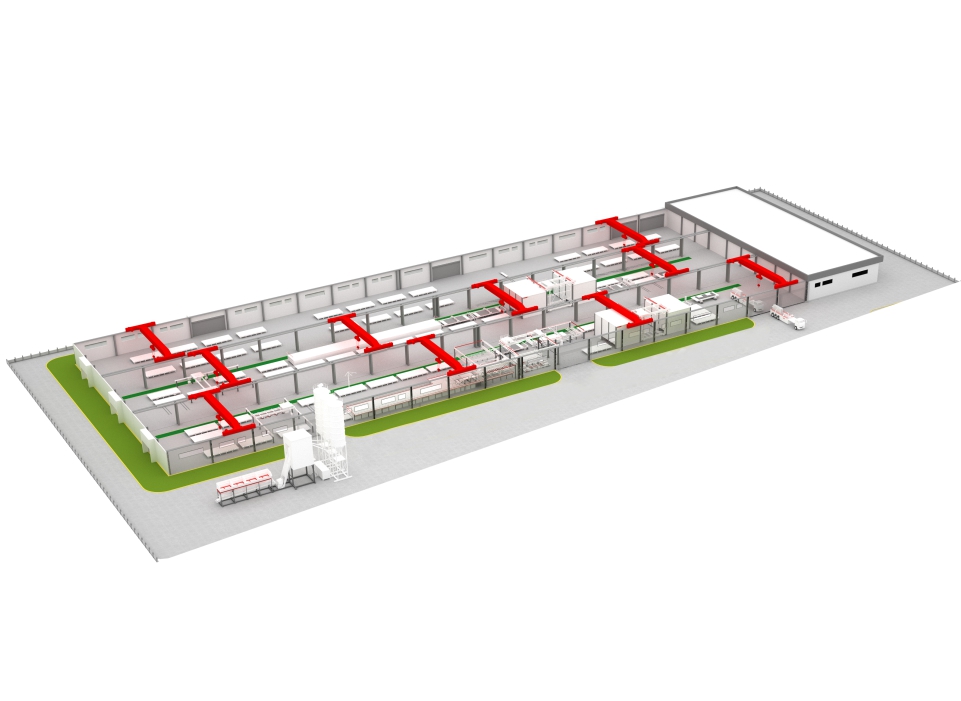

Fan Zesen believes that the development of intelligent construction should be benchmarked against the advanced manufacturing industry and establish product thinking; Abandon going it alone and insist on system integration; Based on industrialization, informatization as a means, and greening as the goal, we will promote industrial transformation with a new construction method that integrates the three modernizations. China Construction Technology will accelerate the transformation of laboratory scientific research results by building an intelligent assembly building production base, and realize "building a house like a car". The intelligent assembly building production base is like an automobile production workshop, 100% robot operation, becoming a "black light factory" of green buildings, workers will work more easily, and the efficiency will be increased by nearly 3 times, and the production base is also a school for training high-skilled construction industry workers.

Ma Yunfei, chief engineer of Sany Construction Engineering and president of the Architectural Design and Research Institute, proposed that industry enterprises must develop in the direction of "digital technology drives the automated production and construction of intelligent equipment, and the big data of automated production and automated construction feeds back the platform and assists decision-making", with "information technology + industrial construction" and "double helix" as the driving force, and "digital platform + intelligent equipment" as the engine to drive the deep integration of the construction industry and digitalization, which is also the advantage of Sany Construction.

Comprehensively improve the ability of system solutions

——From solution to project practice

The development of intelligent construction has become the key to breaking through the bottleneck of development, enhancing core competitiveness and achieving high-quality development in the construction industry. Creating system solutions is an important means to promote intelligent construction. During the meeting, experts from participating enterprises shared their practical experience in intelligent construction solutions.

According to Ma Yunfei, Sany Construction's vision is to become a hard technology company in the era of intelligent construction, "to make the safety of popular building structures low-cost, green and smart to save quickly". Sany Construction Engineering is committed to "industrializing construction", relying on the group's "top three global construction machinery" and the advantages of the industrial Internet of Things, focusing on prefabricated concrete buildings, and creating a "cross-shaped" Sany building industrialization system solution - SPCS. Among them, "one vertical" is the SPCS technical route (cavity wall column + equivalent isomerism + mold technology + in-plane operation), and "one horizontal" is "5231" hard technology (5 types of equipment,Category 2 standards, 3 types of software, 1 Zhuxiang cloud platform).

The SPCS technical route, based on the "cavity wall column" of "multi-faceted without reinforcement, multi-faceted full prefabrication, and large cavity in the middle", adopts the "equivalent heterogeneous" connection method with the same mechanical performance as the cast-in-place structure, and combines it to achieve the construction operation effect of less joints, less formwork and less binding on the site, significantly reducing labor, shortening the construction period, and ensuring the overall safety of the structure without water leakage. In the cast-in-situ position of the structure, the "mold technology" is used to realize the advantages of convenient mold installation and dismantling, saving manpower and improving efficiency, and good structural forming effect. The construction method of "in-plane operation" cancels the traditional outer scaffolding, and all the construction processes are completed in the structural plane, which saves the process and cost of erecting and dismantling the outer frame, and fundamentally eliminates the potential safety hazards of falling from high altitude brought about by the construction of the outer frame. The overall construction efficiency of the scheme is high, and the standard layer construction can be realized for 3~5 days/layer.

SPCS makes every effort to build "5231" hard technology, realizes the digital drive and BIM (Building Information Modeling) twin delivery of the whole process of project E/P/C (design/production/construction), successfully solves the two major pain points of safety and quality of prefabricated building structures and high cost, and helps realize the intelligent construction mode of "from construction to product, from construction to manufacturing, from offline to online".

After a lot of theoretical analysis, experimental research and engineering practice, SPCS is safe and reliable under the design, production and construction conditions that meet the current standards, and has a wide range of application prospects. With "information technology + industrial construction" and "double helix" as the driving force and "digital platform + intelligent equipment" as the engine, Sany Construction Engineering drives the construction industry to fully integrate with digitalization.

It is understood that the SPCS building industrialization system solution has been applied in the country with a cumulative construction area of nearly 10 million square meters, which reflects the advantages of structural safety, low cost (equivalent to cast-in-situ aluminum mold), green wisdom, and good speed and saving (good quality, fast construction, and labor saving). Among them, the Beijing Changping Xiejiazhuang project and the Future City Innovation Base project won the Beijing Structural Great Wall Cup, and the Tianjin National Synthetic Biology Center project won the "Luban Prize".

In addition, Sany Global Science and Technology Innovation Center, a benchmark project for intelligent construction that Sany Construction is committed to building, is in full swing. The project is located in Huilongguan Industrial Park, Changping District, Beijing, with a total construction area of 111,844.92 square meters, and the main construction contents include Sany Heavy Industry Global Headquarters, Sany Intelligent Manufacturing Headquarters Industrial Equipment Technology Pre-research Center (product intelligence, new materials, new processes, new technologies and other general R&D centers), industrial Internet platform, industrial service platform and innovative technology experience center. The total construction area of Sany Intelligent Manufacturing Acceleration Base Project (Phase I) is 36,339.81 square meters, and the construction content is the core production and R&D plant. The center will strive to build a global scientific research highland for construction machinery and new energy, and will strictly follow the relevant policies and requirements of Beijing and Changping District on the development of "high-tech" industries, adhere to high-end, service-oriented, agglomeration, integration, and low-carbon development, strengthen scientific and technological innovation capabilities, accelerate the pace of industrial transformation and upgrading, provide solid and strong support for the high-quality development of Sany, and provide a steady stream of power for the innovation and development of the capital.

Comprehensively improve the service capacity of the whole process

——From full lifecycle management to full scenario services

During the meeting, the guests expressed special concern about the Zhuxiang Cloud Construction Industry Internet Platform built by Sany Construction. Xiao Xuwen said that it is necessary to build a digital construction system management and control platform based on the Internet. Wang Xianjun, vice president of Glodon Technology Co., Ltd., believes that the core of the digitalization of the construction industry is the industrial Internet, and in this regard, Sany Construction Engineering has been at the forefront of the industry.

Zhuxiang Cloud Construction Industry Internet is a systematic software and data platform with independent intellectual property rights, relying on the industrial Internet technology of tree root interconnection, it realizes the online collaboration of "full cycle, related roles and related elements" of the project, and provides digital overall solutions for intelligent construction. The platform includes five core modules: project management, detailed design management, component production management, on-site construction management, and BIM digital twin delivery, which supports users to carry out platform planning, customized design, digital factory automated production, digital site intelligent construction, one-yard twin delivery and data operation, which is conducive to the interconnection of the construction industry chain.

What's more noteworthy is that with the help of this platform, ecological partners can not only realize the full life cycle management of construction projects from planning to delivery, but also put forward requirements on the platform, provide services, and realize transactions on the platform. Sany Construction is the operator, through the integration of Sany Group's intelligent manufacturing and intelligent construction resources for "players" to share and empower "players".

At present, the platform has been selected by the Ministry of Housing and Urban-Rural Development as a "Typical Case Collection of Intelligent Construction New Technology and New Product Innovation Services".

Based on the concept of "platform planning, customized design, full simulation, digital factory, digital construction site, participation experience, twin delivery, and data operation", Sany Construction and Sharing Cloud Platform has opened up the five stages of intelligent construction of "intelligent planning, intelligent design, intelligent manufacturing, intelligent construction, and intelligent operation", realized the online collaborative management of the whole life cycle of the project, related roles, and related elements, and empowered the whole process of E/P/C with science and technology.

In the investment and planning stage, Sany Construction developed the SPCP/D plan and data management system. The system provides a large number of model project templates to help managers quickly plan project plans; Each participant can work together to prepare a project plan covering the pre-project, design, production, construction and delivery; And based on the schedule, predict the human resources, component arrival, equipment demand, and capital demand; The task is detailed to the component and process level, and the progress information is dynamically summarized; Project issues can be communicated with multiple parties at any time to realize online collaborative management of the whole project cycle, related elements, and related roles.

In the intelligent design stage, Sany Construction Engineering and China Academy of Building Research have joined forces to create a domestic intelligent deepening design software PKPM+SPCS, which solves the problems of difficult BIM design collaboration, data scattering, and low application in the industry, and realizes many functions such as automatic splitting, rapid deepening, compliance calculation, intelligent optimization, one-click charting, data support, etc., so as to make prefabricated building design better, faster and easier.

In the intelligent production stage, Sany Construction Engineering develops SPCI digital solutions, connects with mainstream BIM design software such as PKPM, PlanBar, Revit, analyzes the design data and reorganizes the production process data according to system standards, and directly sends it to SYMC/PLC and other controllers, and drives intelligent equipment such as marking, molding, pouring and maintenance of PC production lines through industrial technologies such as servo control, so as to achieve digital and intelligent and efficient production. At present, the newly built PC digital factory of Sany Construction Engineering can greatly improve the level of industrial production, compared with traditional assembly line production, the number of workers is reduced by 50%, the cycle time is shortened by 50%, the production capacity is increased by 40%, and the annual production capacity of a single line design can reach more than 30,000 cubic meters. In terms of market performance, Sany Construction Intelligent PC Equipment has a domestic open market share of more than 50%, with customers all over the world, and the number of sales has exceeded 800 production lines. At the same time, Sany Construction Engineering has developed a PCM component (factory side) management system, which is oriented to PC factories and tracks and manages business processes such as order items, component production, quality, yard, and shipment based on a one-by-one component list. The PCM component (factory-side) management system strives to help front-line personnel with simple functions, make production behaviors traceable with small management costs, feedback production status with real data, and support factory decision-making in an intuitive way.

In the intelligent construction stage, Sany Construction opens up the collaborative management of the factory and the construction site, and extends the PCM component management system to the construction link. At present, the PCM component (construction end) management system provides functions such as cargo collaboration, hoisting construction management, and one-yard hoisting record based on component data, so as to realize the traceability of the whole life cycle of components and the delivery of BIM twins. At the same time, Sany Construction also built a data operation cockpit. Using information technologies such as the Internet of Things, big data and cloud platforms, it provides a one-stop cockpit data platform to realize the integrated supervision of production, delivery, equipment, energy, etc. of all factories, and visually monitors and analyzes the project construction site from the enterprise and project levels, so as to provide "one-stop" decision support for the management.

In the operation and consumption stage, Sany Construction can provide mobile crushing and recycling equipment for the consumption of construction waste, recycle building concrete and steel bars, create secondary value, and promote green and low-carbon development.

Experts believe that at present, there are very few solutions that can truly realize the collaborative control of all elements, all participants, and the whole process of intelligent construction. Sany Construction's spirit of innovation, continuous iteration, and expansion of new scenarios in perseverance is commendable.

The relevant person in charge of Sany Construction Engineering said that in the future, Sany Construction Engineering will join hands with relevant departments to gather resources and practical experience from all parties, continue to lead the development of the industry, contribute better Sany solutions, more Sany wisdom and stronger Sany strength to the coordinated development of intelligent construction and building industrialization, and make unremitting efforts to realize the grand vision of "making popular building structures safe and low, green and smart and fast and saving".

Sany PC integrated automated production line

SPCE smart PC equipmentRecommended products

PC production line

Sany PC integrated automated production lineRelated testimonials

Changsha Housing and Construction Special Report - Sany Construction Engineering "Building and Enjoying Cloud Platform and PC Intelligent Production Line"

2025.06.20

Sany silicon energy "wins" Africa

2025.06.18

CCTV Finance × Sany Heavy Industry: Transportation construction continues to heat up! In May, the infrastructure was full of bright spots →

2025.06.17

0 comments