Wu Xiaobo: In Changsha, I met the world's leading construction machinery

2022.05.07

Wu Xiaobo Channel

From May 16th to 17th, Wu Xiaobo Channel will join hands with Feishu to enter the benchmark factory - Sany Heavy Industry, and Mr. Wu Xiaobo will lead you to visit the leading "lighthouse factory" in the construction machinery industry, as well as the heavy truck factory that is open for the first time, and take a look at the digital and intelligent practices behind the "big country heavy equipment".

Text / Ba Jiuling (WeChat public account: Wu Xiaobo channel)

As the famous "lighthouse factory" of Sany Heavy Industry, No. 18 factory has always been not allowed to take pictures. We can only learn about it from sporadic news reports, and this time we have the opportunity to experience it for ourselves.

At 10 a.m. on April 22, when we arrived at Factory No. 18, which covers an area of about 100,000 square meters, the factory was in full swing. Walking on the tour road of the assembly line, workers are assembling the pump trucks on the assembly line. In a huge, bright and clean modern space, all the negative impressions of the factory seem to have vanished.

Mr. Wu said in "Let's Go with Me to See the Factory" in March this year that China is becoming the world's most radical industrial intelligence testing ground. The logo is: China has 31 of the 90 "lighthouse factories" in the world (considered "the world's most advanced factory") rated by the World Economic Forum, the largest number.

With the announcement of the eighth batch of "lighthouse factories" in April, the number of Chinese factories has risen from 31 to 37 out of a total of 108 factories, further consolidating the advantage.

In September 2021, Sany Heavy Industry's Beijing pile driver factory became a "lighthouse factory" certified by the World Economic Forum, which is the first certification of the World Economic Forum in the field of heavy industry, which means that Sany has obtained the right to speak at the forefront of the world.

In mid-May, we will have the opportunity to visit the No. 18 factory of Sany Heavy Industry's "Lighthouse Factory" in Changsha, Hunan Province. To this end, the minibus took the lead in going to the Sany Heavy Industry Factory in Changsha County Economic Development Zone, Changsha, to obtain some information and share it first, so as to help everyone have a deeper understanding during the inspection.

Two Sany pump trucks made a gesture

It means "welcome to visit"

Why should you watch it?

In 10 years, 30,000 fewer employees have been lost, and sales have more than doubled

Sany Heavy Industry Co., Ltd. is located in Changsha County, Changsha, Hunan Province - the local construction machinery industry and automobile and parts industry are well developed, and it is among the top ten counties in China all year round.

As a well-known "Internet celebrity city" in the country, Changsha is famous for eating, drinking and having fun. In Changsha City, Hunan Province in late April, the sun is shining and the wind is smooth. The food billboards on the streets are abundant, bright and bright, and the young men and women on the streets are enthusiastic and unrestrained. But what many people may not know is that this "entertainment capital" has such a hardcore heart.

What about Sany Heavy Industry? It is the general existence of the C position in Changsha County. The sales volume of its three major product lines in the world leads the market: in 2021, the sales volume of excavation machinery will exceed 100,000 units, ranking first in the world for two consecutive years; Concrete machinery ranks first in the world; Medium and large crawler cranes ranked first.

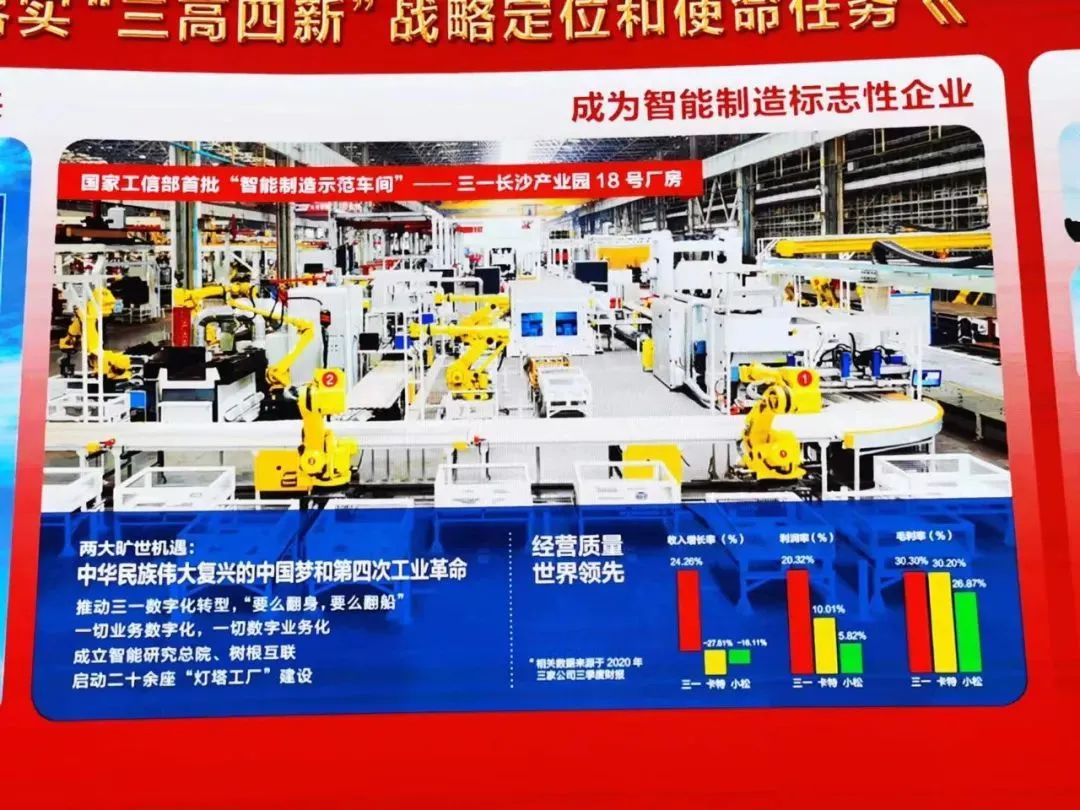

Before talking about Sany Heavy Industry's "lighthouse factory", it is necessary to understand an important background, which can be easily expanded through a picture.

Sany Heavy Industry Display Wall

We see such an introductory chart in the Sany history display column, in which the sales over the years are very eye-catching:

In the ten years from 2009 to 2019, Sany's sales showed an S-shaped curve, increasing from 28.3 billion yuan in 2009 to 75 billion yuan in 2011, and then declining to 30 billion yuan in 2016 for five consecutive years, and returning to the level of 700-100 billion yuan in 2018 and 2019. After 2019, there has been a leapfrog development, climbing from 100 billion to 172 billion in 2021.

It should be emphasized that the construction machinery industry has obvious cyclical changes due to upgrading, infrastructure policies and other reasons, so it is normal for sales to fluctuate sharply. However, it is obvious that Sany Heavy Industry has effectively broken free from the shackles of the previous cycle and entered a new stage and a new development cycle.

Why is that? On the basis of intelligent transformation, it is the core reason to promote Sany Heavy Industry to move towards intelligence, electrification and internationalization.

Since 2019, Sany Heavy Industry has invested tens of billions of funds, relying on the root interconnection industrial Internet operating system - root cloud platform, to start the intelligent upgrade of more than 20 factories to meet the standard of "lighthouse factory". With the help of 28 "lighthouse factories" such as No. 18 factory and Beijing pile driver factory, Sany Heavy Industry has made leapfrog progress in production efficiency.

For example, the World Economic Forum's evaluation of the Beijing pile driver factory is: "In the context of the increasing market demand and complexity of multi-category and low-volume heavy machinery, Sany Beijing has deployed advanced human-robot collaborative automation technology, artificial intelligence and Internet of Things technology, which has increased labor productivity by 85% and shortened the production cycle by 77%, from the original 30 days to 7 days." ”

Therefore, Sany Heavy Industry told us the following set of data, although it is surprising, but it is not unexpected:

In 2021, Sany's sales reached 172 billion yuan, which is due to the efforts of more than 50,000 employees around the world. In 2011, Sany Heavy Industry's sales were 75 billion yuan, and behind this achievement stood more than 80,000 employees around the world. In other words, in the past ten years, Sany has lost 30,000 employees, but its sales have increased by more than 2 times.

In addition, in 2021, Sany Heavy Industry's net profit margin was 11.6%, and the average net profit margin in the past three years was around 14%, which is at the highest net profit margin level in the past ten years.

What is the legendary Factory 18 like?

Talk about what we've seen and heard

Next, let's talk about Sany Heavy Industry's No. 18 factory, which has three main characteristics:

First of all, it is the earliest "lighthouse factory" that started intelligent modification and the first to achieve stable production; Secondly, it is the core production base of Sany's ace product "pump truck" (the concrete pumping equipment mainly used by workers to pump concrete in high-rise buildings); Third, 90% of the core components of the pump truck come from independent research and development.

Sany Heavy Industry Display Wall

In July 2021, the overseas edition of People's Daily reported on Sany Heavy Industry's No. 18 factory. "The manufacturing cycle of a pump truck has been reduced from 28 days to 17 days, which is a shortening of nearly 40 percent. ”

The data we learned from the site that can be supplemented are: every 40-45 minutes, the pump truck on the assembly line will move one station; The final assembly time of a pump truck is 9-10 hours, and a pump truck is rolled off the assembly line every 15 minutes, and 850 pump trucks are rolled off the assembly line every month; The small and medium-sized pump truck with two axes only needs 2 people to assemble, and the large pump truck with five axles only needs 4-5 people to assemble.

The reason for this efficiency is the large-scale adoption of automation and semi-automation technologies. In the words of Hou Yanfeng, manufacturing director of Sany Heavy Industry Pumping Company: "In the No. 18 plant, everything that can be done with machines will never be done by people, and everything that can be operated remotely will never come to the site to do it." ——The landing effect is: "from a steel plate cutting to the whole vehicle off the assembly line, the whole process of intelligent production".

Breaking it down, we've summarized the following key "highlights":

◎ The industry's first automatic blanking and forming production line, from steel plate to parts to achieve unmanned production.

◎ The intelligent welding robot with visual recognition module can automatically identify materials for welding, and has flexible production capacity.

◎ Intelligent coating, independent adaptation to spraying procedures, intelligent spraying.

◎ The manipulator and the intelligent sorting equipment cooperate to complete the intelligent sorting of large, medium and small parts.

◎ The automatic transport trolley with robot vision technology will provide workers with material and parts extraction and distribution services.

◎ Intelligent debugging, real-time online monitoring of the debugging process, real-time recording and early warning of debugging faults, so as to promote the qualified delivery of the whole machine.

For example, the attractive automatic transport trolleys have two characteristics: they are transported along a fixed route and automatically stop when they encounter obstacles. When the pump truck flows to different workbenches with a certain movement frequency, the automatic transport trolley has already prepared the corresponding amount of materials on the material storage table next to it.

According to the relevant person in charge of Sany Group: "(When) the MES (Manufacturing Execution System) issues an instruction, the laser-guided AGV (automatic transport trolley) will automatically pick up the goods from the three-dimensional warehouse, and then send the spare parts to the corresponding station. ”

In addition, 8 plasma cutting machines equipped with robot vision technology can cut steel plates of different shapes according to different demand instructions, which solves the inefficiency problem that traditional automatic cutting machines can only cut steel plates of the same shape.

Once the steel plates have been cut, they are sorted and grabbed by eight robotic arms into different sub-loading frames, while automated transport robots are already on the sidelines, sending some of the plates to the final assembly line and the other to the polishing line. Therefore, Sany Heavy Industry can realize mixed line production, and pump trucks of different specifications and models can be mass-produced.

Intelligent sorting

In addition to Factory 18, we also visited the larger 680,000-square-meter Smart Heavy Truck Industrial Park, which opened to the public for the first time. On the final assembly line, you can see a three-dimensional workspace that includes a network of aerial and underground transports in addition to the workbench on the ground, mainly transporting engines and gearboxes.

The assembly workshop of the intelligent heavy truck industrial park

In addition to the excavator index

What else can Sany do with big data analysis?

As many of you may know, in February this year, we launched our report, "Excavator Index: A Micro Interpretation of the Rise of Great Powers", which details the famous Excavator Index.

To put it simply, the excavator index is built by Sany Heavy Industry based on the "Root Cloud Platform", the industrial Internet operating system of Tree Root Interconnection, and has the reputation of "China's economic barometer" (it is understood that Tree Root Internet has deep experience in the digital transformation of service equipment manufacturing enterprises, and is very familiar with the processes and processes of industry leaders such as Sany). In addition, the report and promotion of CCTV Finance and Economics have been adopted by relevant high-level officials as one of the reference economic indicators, and its influence is quite wide.

At the site, we experienced the "Root Cloud Platform" firsthand. With the help of the terminal touch screen, it can be found that the national equipment operating rate in April was about 47.2%, higher than the average of 45%. For example, the operating rate of equipment in Hunan Province is 46.6%, that of Zhejiang Province is 63%, and that of Tibet is 30%. It can also be divided into provincial capitals, such as Hangzhou, which is 69%. At the very least, you can observe the equipment start-up situation in a prefecture-level city.

Since 2008, all the engineering equipment sold by Sany Heavy Industry, including pump trucks, excavators,Mixer trucksand so on, all of which have been managed by the network. Specifically, each device is equipped with an SoC controller. This is equivalent to installing a flexible "brain" for these dumb large machinery and equipment, which can record their location, fuel consumption, working status and other data information.

Today, there are 790,000 networked devices, and these "brain" information is transmitted to the "root cloud platform". Because these large-scale engineering equipment are closely related to the infrastructure situation, we can understand the basic situation of the infrastructure in the country and various provinces and cities, and inspire us to think about the economic situation in the country and all over the country.

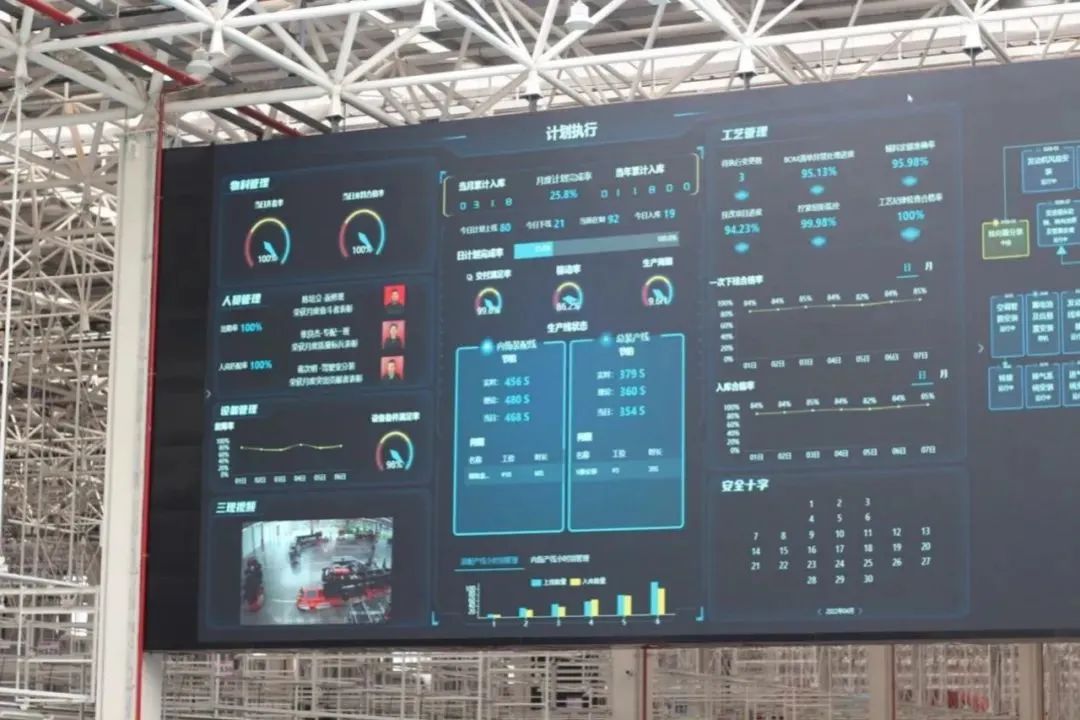

In addition, the "root cloud platform" can also clearly display the data status of 12,000 intelligent production equipment of Sany Heavy Industry, which is supplemented by 36,000 intelligent cameras, which can play a role in efficient management of factory production.

For example, the Sany explainer randomly pointed out a device located in Ningxiang Industrial Park, Hunan, which has an online rate of 100%, but only 37% of the operation rate, which is in an unqualified state (these data are updated in real time every two minutes).

For another example, at 5:53 p.m. on April 20, in the factory in Huzhou, Zhejiang, a smart camera captured a violation, and the screen showed that there was a shaky red box marking the garbage in the corresponding area that had not been cleaned up in time.

If a worker is not wearing a helmet or playing with a mobile phone, it will also be captured in real time. - Different color annotations indicate different objects and states, for example, portraits are marked with blue boxes, and even solder joints are captured.

Sany Heavy Industry displays a large screen

In Sany Heavy Industry's own words, Sany Heavy Industry has realized the "interconnection of three presents and four tables". The "three tables" refer to the scene, reality, and the present, the "four tables" are the water, electricity, gas, and oil meters, and the "interconnection" is to move the management of the "four tables" to the "root cloud platform" around the above three sites. – This is what surprised us in addition to the excavator index.

Finally, with the help of Feishu software, which is commonly used by Sany Heavy Industry, the "Root Cloud Platform" has established a fast information circulation channel with Sany Heavy Industry's employees. All kinds of information from the "Root Cloud Platform" can be quickly sent to the mobile phones of relevant persons in charge and employees through Feishu to facilitate efficient response. In addition, with the help of various functions of the Feishu platform (Feishu reading meetings, documents, calendars, etc.), collaborative and efficient office, Feishu attendance is used to punch in and arrange shifts, and Feishu OKR is used to complete the alignment of goals up and down, so that the heart is in one place.

Go to Changsha and meet the global construction machinery leader in the future

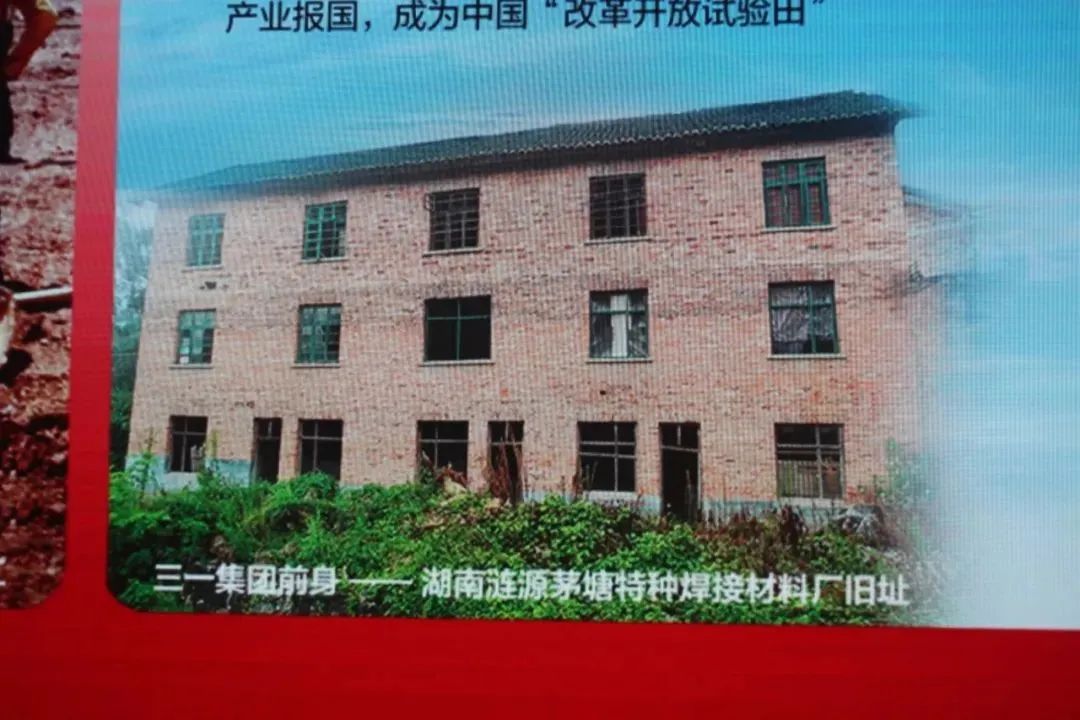

In 1989, the predecessor of Sany Heavy Industry was born in a factory in Datong Village, Maotang Township, Lianyuan, Hunan Province, and initially made special welding materials.

Sany Heavy Industry Display Wall

In 1991, it was renamed Sany Group. Over the past 20 years, Sany Heavy Industry, which focuses on research and development and takes "quality changes the world" as its slogan, has a strong international influence.

At that time, there were two events: in August 2010, the San Jose copper mine in Chile collapsed, and 33 miners were trapped in the mine at a depth of more than 700 meters, and all of them survived, among which an important rescue role was a 400-ton crawler crane provided by Sany, which was remade into the movie "Rescue by the Center of the Earth" by Hollywood directors.

In March 2011, a nuclear leak and explosion occurred at the Fukushima nuclear power plant in Japan. The Japanese government sent a letter to Sany for help, hoping to support a 62m pump truck. Sany donated a pump truck worth $1 million free of charge. The device pumps seawater to the reactor to cool down.

However, with the global construction machinery industry cooling down for five consecutive years, in 2016, Sany Heavy Industry's sales fell to only 30 billion yuan, and the net profit was only 200 million yuan.

In March 2018, Liang Wengen said at the "representative channel" of the two sessions: "The digitalization of Sany will capsize if you don't turn over." As a result, in 2019, Sany Heavy Industry took out tens of billions of funds to start a vigorous digital upgrade.

A leader of Sany Heavy Industry told us that this is something without precedent, and it is a way to ensure that production capacity is not reduced, and transformation is carried out while producing. To this end, most of the employees involved in the transformation "ate and lived in the factory from January to February", and "the chief engineer stayed in the factory for a month in order to troubleshoot the problem".

According to the 2021 global top 50 construction machinery manufacturers list released by KHL Group, an engineering information provider, Sany ranks fourth in the world, up 8 positions from its ranking in 2016.

There are three main products of Sany Heavy Industry, including excavation machinery, concrete machinery, and lifting machinery. In 2021, revenue accounted for 39%, 25% and 25%, respectively. Taking the global competitiveness of the main product excavation machinery as an example, according to the list of the top 20 global excavator manufacturers in 2021, Sany Heavy Industry also ranks fourth in the world.

From a global point of view, Chinese companies mainly lag behind two global giants, Caterpillar and Komatsu, a Japanese company. However, we also found that Sany Heavy Industry's R&D investment in the industry has become more and more obvious, and the future can be expected over time.

Source: Huachuang Securities

In January 2022, 66-year-old Liang Wengen stepped down as chairman of the listed company Sany Heavy Industry, and 59-year-old Xiang Wenbo took over. Liang Wengen, as the actual controller of Sany Heavy Industry, will focus more on the direction of "three modernizations", which means that Sany Heavy Industry has officially entered a new era.

Now is the time to look at Sany Heavy Industry and meet a surging future global construction machinery leader.

Mixer truck SY412C-8H( VI.)LNG

Mixer trucksRecommended products

SY412C-8H( Ⅵ )LNG

Mixer truck SY412C-8H( VI.)LNGNext article:99 meters long! Sany Renewable Energy Manufacturing!

0 comments