Paint + cab fully upgraded! Sany set off a quality revolution

2025.02.25

Sany Group

For more than 30 years, with extremely low downtime, Sany Equipment has become a reliable partner on the road to entrepreneurship for customers. At present, Sany Group has once again launched a charge towards the corporate mission of "quality changes the world".

In October 2023, Sany Group officially launched the "Quality Upgrading Campaign", implementing the values of "quality is the starting point of value and dignity" and "quality is the only thing that cannot be compromised" into all aspects of the group's operation, taking a solid step towards the strategic goal of creating "world-class products".

Let the quality culture go deep into the bone marrow

Since the launch of the quality upgrading campaign, Sany Group has attached great importance to it, and the leaders of the group have entered the game. As of February 5, 2025, the rotating chairman's luncheon meeting of Sany Group has scheduled 122 quality upgrade campaigns, and the military commanders of each business department have taken the lead in going deep into customer sites, supplier sites, and production sites, participating in 562 "three present" activities, raising a total of 2,533 questions, solving 2,157 problems, and solving problems 25%, with a problem closure rate of 85%.

In Sany restarted Ningxiang Park,craneThe explosion diagram model of the chassis wiring harness is displayed on the quality kanban of the production site, and combined with a series of fault case information for classification and annotation, providing daily quality training for front-line team personnel.

In Sany Port Machinery Zhuhai Park, the "three noes" principle is marked on the eye-catching position of the quality kanban - "do not accept substandard products, do not manufacture substandard products, and do not flow out substandard products", so that the quality alarm bell will ring in the hearts of front-line employees.

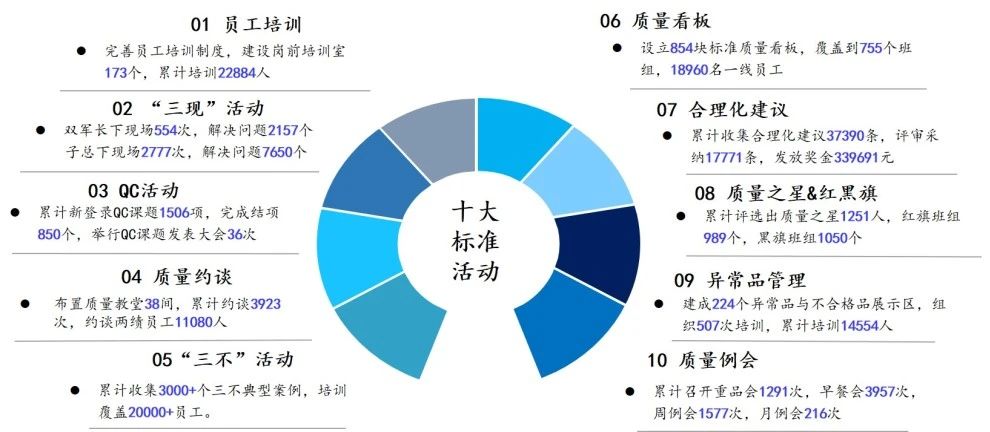

In addition, through the construction of the "Ten Quality Actions" such as regular quality meetings, QC activities, and abnormal product management, Sany has provided strong support for the systematic implementation of quality culture and management.

Note: Data as of January 9, 2025

Putting on a sturdy "armor" for your equipment

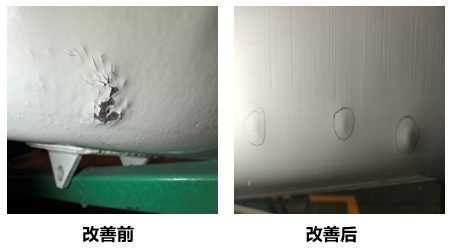

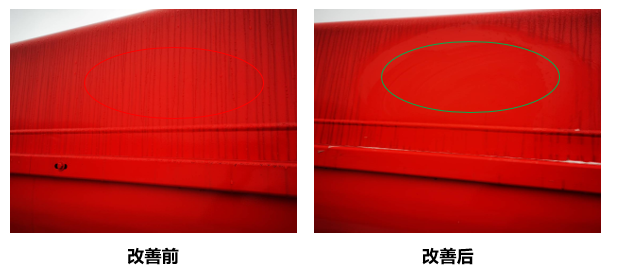

As a key barrier for construction machinery to resist corrosion and prolong its life, the paint coating process is directly related to the life cycle value of the product. With the intensification of global market competition and the growth of demand for extreme working conditions, Sany Group has carried out a "paint revolution" in various product production lines in the quality upgrade action.

The polyurea coating developed for the heavy-duty truck chassis realizes 2-hour self-drying technology, breaking the constraints of the traditional baking process on the production cycle; The development of high-gloss stain-resistant coatings, the surface gloss of crane paint has been increased from 75GS to 85GS (↑13%), and the anti-fouling ability has been increased from level 4 to level 2 (↑2); The development and application of powder coating with high mechanical properties, the impact resistance of the coating is increased by nearly 7 times, and the paint is not peeled off under 40Mpa high-pressure washing, which meets the customer's requirements for the use and maintenance of the product under high-demand working conditions; Through the independent development of high-anti-corrosion nano-varnish, the anti-corrosion ability of standard parts and electroplated parts is increased by 50%, and the problem of easy rust of traditional bolts is overcome.

At present, the "paint revolution" has increased the uniformity of coating film thickness by 18.06 percentage points, the adhesion of the coating by 9.66 percentage points, the curing efficiency by 31.26 percentage points, and the leak detection and protection ability of corners by 29.9 percentage points. Sany Equipment is building a quality defense line for global customers with a more reliable "steel coat".

Millimeter-level polishing reconstructs the driving experience

The cab design has a direct impact on the operator's productivity and occupational health. In the quality upgrade action, Sany Group launched the "Cab Revolution" to reshape the operating experience from millimeter-level details:

Optimize the opening force of the car door to make every entry and exit easy; Adjust the field of view of the rearview mirror to eliminate blind spots; The seat width is adjusted for different market users, helping operators around the world to maintain a comfortable posture during continuous operation; In view of the problem of poor air tightness of the profile adhesive strip, switch the integral door adhesive strip......

eyePreviously, 24 new cabs have passed 44 rounds of rigorous evaluation, and 184 improvement achievements have been accepted by experts at home and abroad with "zero dead ends". In response to the new problems found in the review, Sany has included them in the 2025 continuous improvement plan, and protects all Sany equipment operators with extreme details.

Embedding a "digital brain" for quality control

In the quality upgrade campaign, Sany Group unveiled a new weapon of digital intelligence, the Quality Management Combat Platform (iQMP), to empower R&D personnel, quality assurance personnel, business personnel, production personnel and managers with digital intelligence, so that quality control can shift from "extinguishing fires after the fact" to "predicting the future".

iQMP pulls through a series of basic equipment data, equipment operation data, supply record data, material-related purchase prices, etc., and generates quality control maps for quality inspection planning, historical production of unqualified products, after-sales failures and other information, prints, postes, and embeds key quality control points into the large screen of the station kanban, and workers can see the quality alarm model and quality risk prompts in time when they look up, so that hidden dangers can be intercepted in the embryonic stage.

In addition, iQMP builds online improvement tools such as A+, heavy products, 8D, containment/anti-recurrence, and high-risk supplier management to track product quality problems in a closed loop, build quality cost analysis charts, and provide decision-making basis for the next round of R&D of the same type of products to improve quality and reduce costs. Thanks to the construction of this "digital line of defense", in 2024, the start-up failure rate of all Sany products will be significantly reduced.

Build excellent product competitiveness and move forward side by side with global builders. Sany Group will continue to deepen the quality upgrading movement, and write a quality legend for the industry with millimeter-level insight!

0 comments