Sany Heavy Industries Sany Heavy Industry (SH:600031)

Trinity International Sany International (HK:00631)

Trinity Renewable Trinity Renewable Energy (SH:688349)

Home > Trinity News > Lighthouse factory black technology! The industry's first AR intelligent warehousing system is here

Lighthouse factory black technology! The industry's first AR intelligent warehousing system is here

2021.10.12

Recently, the industry's first intelligent warehousing system based on AR and voice recognition technology officially passed the acceptance at the Sany Pile Crane Lighthouse Factory, marking a major upgrade of Sany digital warehousing.

The system was developed and designed by Shengjing Intelligent Technology (Jiaxing) Co., Ltd., a subsidiary incubated by Sany Heavy Industry Intelligent Research Institute, and was put into use at the Sany Pile Lighthouse Factory on April 15 this year, taking over the picking and distribution tasks of the pile rig lighthouse factory warehouse, and becoming a highlight of the pile rig lighthouse factory certification, helping the pile rig factory become the first lighthouse factory in the global heavy industry industry.

AR picking scene

In the digital transformation of "capsize without turning over", AR is one of the core technologies, and Liang Wengen, chairman of Sany Group, has emphasized the importance of AR applications in internal meetings many times.

As a pioneer in the group's digital transformation, Shengjing Intelligent is targetedwarehousing and logisticsThe scene took the lead in taking action, creating the industry's first intelligent warehousing system based on AR and voice recognition technology, achieving 100% replacement of the picking process, 60% replacement of the distribution process, and more than 60% reduction of the picking error rate.

AR delivery scenario

Strong allianceOvercome speech recognition technology in high-noise environments

In manufacturing plants, the presence of noise makes speech recognition a challenge.

Shengjing Intelligent and Rokid, a leading AR company, used deep learning end-to-end modeling and lossless offline decoder technology to successfully overcome speech recognition technology in high-noise environments.

At present, in a typical manufacturing plant, that is, in a noise environment greater than 90 decibels, the offline instruction recognition rate is greater than 92%, which successfully solves the problem of the application of speech recognition in the manufacturing plant.

Schematic diagram of speech recognition model network based on deep learning

Free your handsRealize online, digital and transparent warehousing

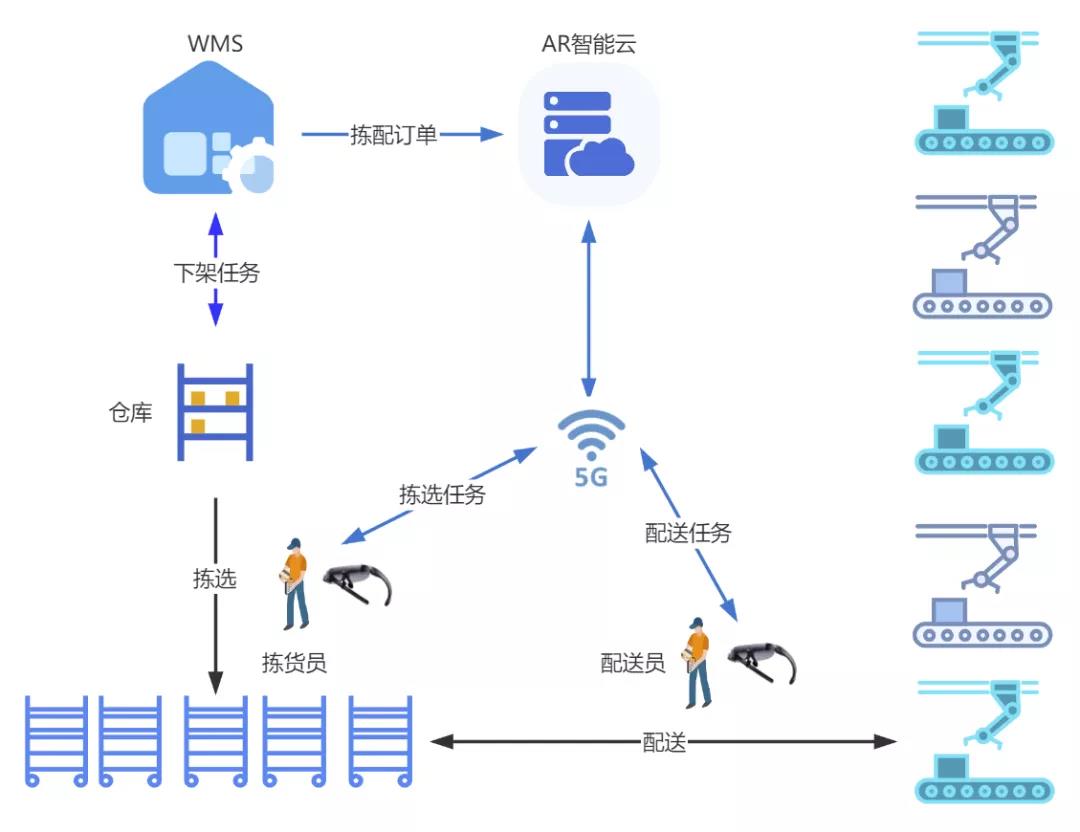

At the same time, Shengjing Intelligent opened up the group's WMS warehouse management system and AR intelligent warehousing system, eliminated paper picking and distribution, and realized intelligent dispatch, intelligent sorting and intelligent distribution.

The AR intelligent warehousing system sends picking and distribution tasks to employees' AR glasses in real time through the 5G industrial cloud private network, and sorters and distributors receive picking and distribution tasks through AR glasses, and the whole process of voice interaction frees employees' hands and improves operational efficiency.

After the task is completed, the system will automatically generate picking and distribution reports in the background to achieve digital records of the operation process of each link.

AR intelligent warehousing system

Through the accumulation of big data, the AR intelligent warehousing system can also accurately construct a portrait of warehousing business behavior, solving common problems such as unreasonable performance evaluation of salesmen and difficulty in process optimization.

The second phase of construction is in full swingAR applications are fully rolled out

At present, the second phase of the intelligent warehousing system is in full swing, through the use of the AI application platform of the General Institute of Intelligent Research, the introduction of more intelligent technologies such as visual recognition and video analysis, empowering tally and inventory business, and building an AR intelligent warehousing system integrating sorting (goods), warehousing (warehousing), pallet (point), picking (goods), distribution (delivery), greatly improving the efficiency of warehousing operations, and becoming a beautiful scenery of the pile rig lighthouse factory.

In addition, Shengjing Intelligent is actively promoting the application of AR technology in Sany Group, and has completed the AR petroleum equipment display at the CIPPE 2021 exhibition with the Petroleum Equipment Division, developed the AR service recorder system with the Heavy Machinery Division, developed the AR intelligent display system for crane working conditions with the Reconstruction Division, and developed the AR remote assistance system with Sany Robot Company.

In the future, Shengjing Intelligent will continue to deepen the digital transformation of Sany, and work with upstream and downstream partners in the industry to jointly promote intelligent manufacturing and product intelligent upgrading, and help China from a "manufacturing power" to an "intelligent manufacturing power".

0 comments