Hunan Daily: The world's largest crawler crane is on the lower line in Sanxia

2011.05.31

Source: Hunan Daily Author: Tang Aiping

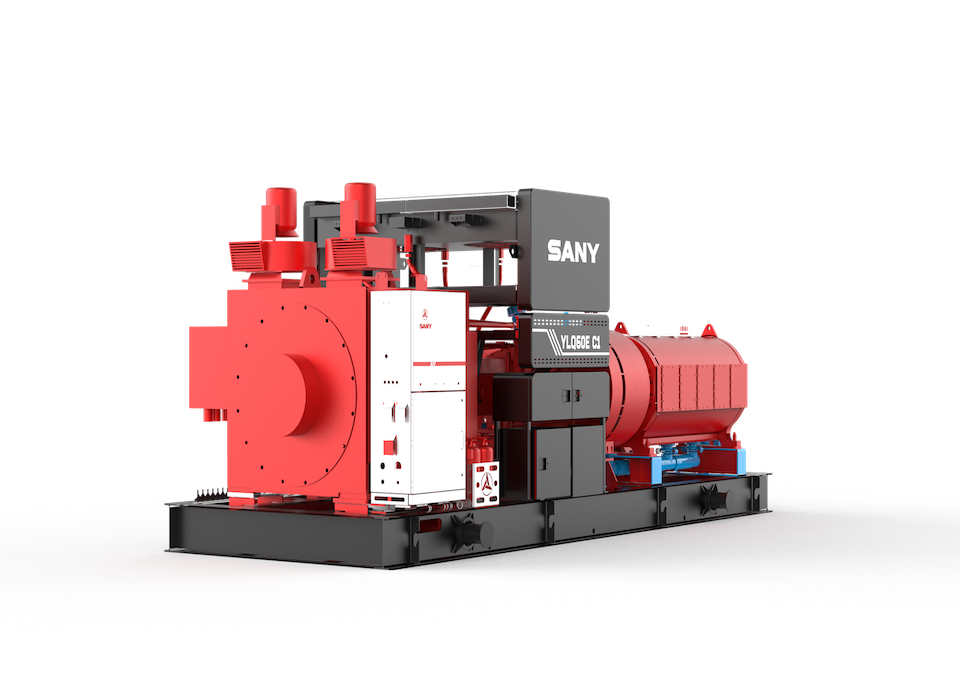

This newspaper, May 29 (Reporter Tang Aiping) Today, Sany Kunshan Industrial Park, a red behemoth once again made Sany Heavy Industry the focus of attention: this super-large tonnage SCC86000TM track, known as "the world's * 5656 crane".craneThe off-line ceremony was held here. The crane is independently developed and manufactured by Sany Heavy Industry, with a lifting capacity of 3,600 tons for *5655 and a lifting moment of 86,000 tons for *5655. Users who participated in the off-line ceremony said that the successful launch of the SCC86000TM (3,600 tons) marks that China has the R&D and manufacturing capabilities of super-large tonnage lifting products comparable to the world, and breaks the long-term monopoly position of foreign brands in the field of extra-large tonnage crawler cranes.

The president of Sany Heavy Industry introduced to Wenbo that Sany Heavy Industry set up a Sino-US joint R&D team of nearly 500 people in 2003 to create the world's most advanced crawler crane production line. Since 2006, Sany Heavy Industry has refreshed the record of domestic crawler cranes again and again. In 2006, the first 400-ton crawler crane in China rolled off the assembly line, which was praised by the industry as "Shenzhou*5656 crane"; In 2008, Asia's first 1000-ton crawler crane rolled off the assembly line in Sany Heavy Industry, which was praised as "Asia's *5656 crane" by the industry. In 2010, the SCC16000 1600-ton crawler crane came out and was successfully applied to the field of nuclear power hoisting. At present, as the first domestic brand crawler crane used in the field of hoisting heavy parts of nuclear power nuclear islands, Sany SCC10000 and SCC16000 1,000-ton super large tonnage crawler cranes have been successfully applied to the field of nuclear power dome hoisting for 8 times, which has ended the history of foreign brand products monopolizing the field of hoisting heavy components of nuclear power nuclear islands, and occupies 53% of the market share of domestic super-large tonnage crawler cranes.

It is reported that the Sany SCC86000TM (3600 tons) crawler crane exceeds the *5655 lifting moment and *5655 lifting weight of all 3200-ton crawler cranes in the world. Its research and development adopts the most advanced limit state design method, digital prototype and Top Down design methods, breaks through the design problems of nonlinear and large deformation metal structures, and takes the lead in applying the high risk coefficient recommended by GB3811-2008 for cranes in the nuclear industry, and has made substantial breakthroughs in structural design and control system. At present, 30 invention patents have been applied, among which the double-chord single-arm joint technology and the double-* hoisting trolley technology have applied for international invention patents in Germany, the United States and other countries.

0 comments