Sany Heavy Industry Sany Heavy Industry Co., Ltd. (SH:600031)

Trinity International Sany International (HK:00631)

Sany Renewable Energy Sany Renewable Energy (SH:688349)

Home > Media coverage > CCTV Finance: The per capita output value exceeds 10 million! This factory is big!

CCTV Finance: The per capita output value exceeds 10 million! This factory is big!

2021.12.19

CCTV Finance

Recently, Sany has dominated the CCTV financial screen again!

Known as the "Oscar" of intelligent manufacturing, the "lighthouse factory" represents the highest level of intelligent manufacturing and digitalization in the global manufacturing field today, and is known as the "world's most advanced factory". In the latest list of "lighthouse factories" in the global manufacturing sector released by the World Economic Forum, Chinese companies came out on top, adding 10 new companies, becoming the country with the most "lighthouse factories" in the world so far.

"Sany Intelligent Manufacturing" in Changping District, Beijing is a new intelligent digital factory built according to Industry 4.0 standards. Not long ago, it was just rated as a "lighthouse factory" by the World Economic Forum, and it is the first certified world "lighthouse factory" in the global heavy industry industry, with an annual output value of more than 10 billion.

Rotary drilling rigsIt is a kind of pile driver, which is specially used as heavy equipment for pile foundation construction in infrastructure projects, and the construction efficiency is more than 10 times higher than that of traditional piling equipment.

Today, the "big guys" produced here are not only exported to more than 60 countries and regions overseas, but also in the forefront of the industry in the domestic market.

These cores are the most impressive examples of the rotary drilling rigs produced by the plant in various infrastructure projects. Today, the "lighthouse factory" produces more than 170 types of drill pipes alone, ranging in length from 13 to 27 meters and weights ranging from 5 to 35 tons.

These rotary drilling rigs of different sizes, weights and functions can be quickly completed on the same production line in this factory.

Zhou Changjian, an old customer in Hebei, has successively purchased 16 different types of rotary drilling rigs from them. Seeing the new product, he hopes that the factory will produce another one according to his needs, and according to his previous experience, he wants to order a rotary drilling rig, and the production cycle will be at least 30 days.

In Zhou Changjian's impression, in order to be able to pick up the goods as soon as possible, it is common to live in the factory and wait for the goods. But what he didn't expect was that the factory promised 7 days of delivery.

A rotary drilling rig can be delivered in 7 days, the production cycle time has been accelerated by more than 4 times, and the monthly production capacity has doubled to 300 units. Where is the secret weapon of the "lighthouse"?

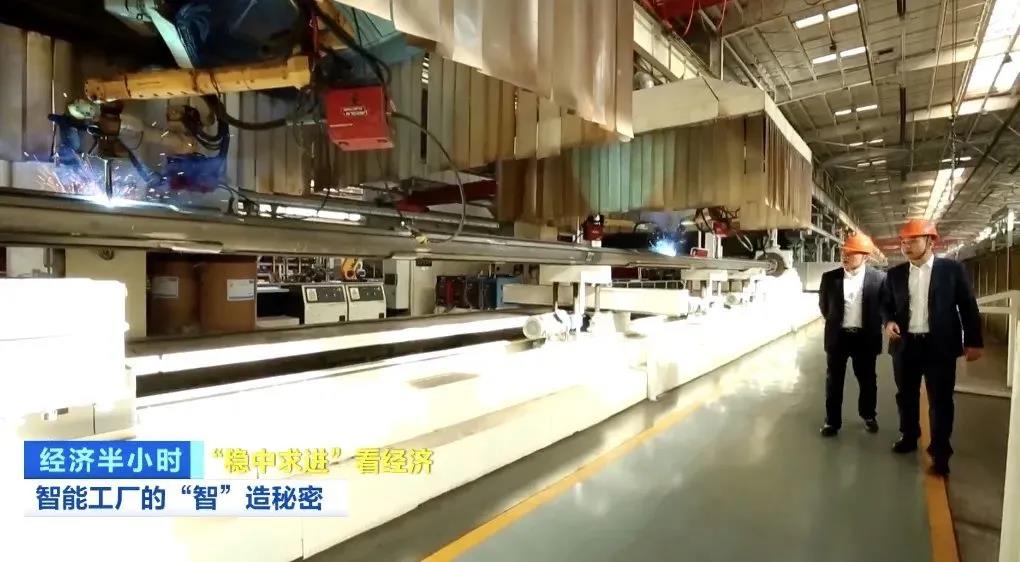

The world's first "lighthouse factory" in the heavy industry welds a 20-meter-long drill pipe that previously required 12 hours of non-stop work by 12 senior welders. Manual welding will also be affected by the physical strength and energy of workers, resulting in the appearance of defects. Today, four robotic arms can weld in less than 8 hours.

In this "lighthouse factory", there are many links like this to replace manual production with intelligence to improve production quality and efficiency: the control center is an "intelligent brain", through which orders can be quickly decomposed into each flexible work island, realizing the whole process from order to delivery data-driven;

The 5G high-definition sensor is the "insight" in the workshop, which can control the operation error of the heavy-duty robot at 0.3 mm, and the realization of smart logistics is handed over to the smart cargo handling "Scud";

With the efficient coordination and decomposition tasks of "brain", "eyes", "hands" and "scuds", it is natural for rotary drilling rigs to ensure quality and quantity and fast delivery.

In order to be able to continuously meet the higher needs of customers, the intelligent upgrading and transformation of this "lighthouse factory" is still in full swing. Not long ago, they just broke through a recognized global problem in the industry.

Dong Mingkai, President of Sany Heavy Industry Intelligent Manufacturing Research Institute

Dong Mingkai said that the world's problem is the welding of drill pipe and square drill bit, this weld with a width of six centimeters and a depth of four centimeters is called a first-class weld by the industry, and it is also the most difficult weld, at least two welders with twenty or thirty years of experience can weld 9 layers and 56 at the same time to complete.

At the beginning of the transformation of the smart factory, Dong Mingkai's team made great efforts here, tried more than 10 kinds of solutions alone, wrote 6 sets of adaptive intelligent control programs for the automated welding guns here, adjusted hundreds of welding process parameter combinations, and realized the automation of this key link after more than 5 months of continuous debugging.

Nowadays, in the "lighthouse factory", robots have replaced workers on the assembly line, and the new type of intelligent manufacturing needs a new type of factory talent: they need to understand both industrial technology, software, and business processes, and human-machine cooperation is creating greater value.

In 2020, the per capita output value of this company's pile driver factory will reach 10.728 million yuan, which is one of the factories with the highest degree of intelligence, the highest per capita output value and the lowest unit energy consumption in the global heavy industry industry, and has become a well-deserved "lighthouse benchmark" in the global heavy industry industry.

At present, in addition to the Beijing pile driver factory, the company has invested 15 billion yuan to launch 46 intelligent manufacturing lighthouse factory upgrade projects in Changsha, Kunshan, Chongqing and other industrial parks, and also realized the real-time interconnection of tens of thousands of production equipment and hundreds of thousands of materials.

Half-hour observation: "intelligent manufacturing" is creating the future of Made in China

In today's program, we see that China's manufacturing enterprises are only fast and not broken, and use the sense of urgency of "not turning over, but capsizing" to promote digital transformation and upgrading. The state pointed out in the "14th Five-Year Plan for the Development of Intelligent Manufacturing" that by 2025, China's manufacturing enterprises above designated size will basically popularize digitalization, and the backbone enterprises in key industries will initially realize intelligent transformation. By 2035, manufacturing enterprises above designated size will fully popularize digitalization, and backbone enterprises will basically realize intelligent transformation.

The digital transformation of manufacturing enterprises is not achieved overnight, and every step needs to be made steadily and steadily. We believe that with the emergence of more and more "lighthouse factories" in China, the future of Made in China will definitely achieve "stable manufacturing" together, which will bring us more surprises.

Recommended products

Next article:People's Daily Focus! Trinity "Elephant Dance"!

0 comments

Related testimonials

The first in the global industry! CCTV walked into Sany Shaoshan Lighthouse Factory!

2024.10.11

Walk into Sany and explore the "success code" of China's intelligent manufacturing

2023.12.14

People's Daily certification: This represents the highest level of intelligent manufacturing and digitalization!

2023.12.06

0 comments