What did Wu Xiaobo see at the Sany Benchmark Factory?

2022.05.19

Wu Xiaobo Channel

Text / Ba Jiuling (WeChat public account: Wu Xiaobo channel)

At night in Changsha, it is a flowing colored light. In those lights, there are electric car lights that deliver milk tea back and forth, neon high-rise buildings dotted on both sides of the Xiangjiang River, moonlight in the sky, and star cities on earth.

At this time, more than 200 people hurriedly finished their dinner and walked into this night illuminated by the lighthouse factory.

This is the last part of the second phase of "Entering the Benchmark Factory", a review class. In the class, they reviewed what they saw and learned when they visited Sany Heavy Industry No. 18 Factory and Heavy Truck Factory in the morning, as well as the sharing session with He Dongdong, co-founder and CEO of Tree Root Internet, Liu Yan, President of Sany Heavy Industry Intelligent Manufacturing Research Institute, Shi Zhijun, Vice President of Feishu, and Mr. Wu Xiaobo.

"What touched you the most about this study tour?"

The most frequently mentioned points by the participants were:

01Degree of unmanned

The main plant of the 200,000-square-meter heavy truck factory can roll off the assembly line every 10 minutes, and there are only 132 workers and managers in total.

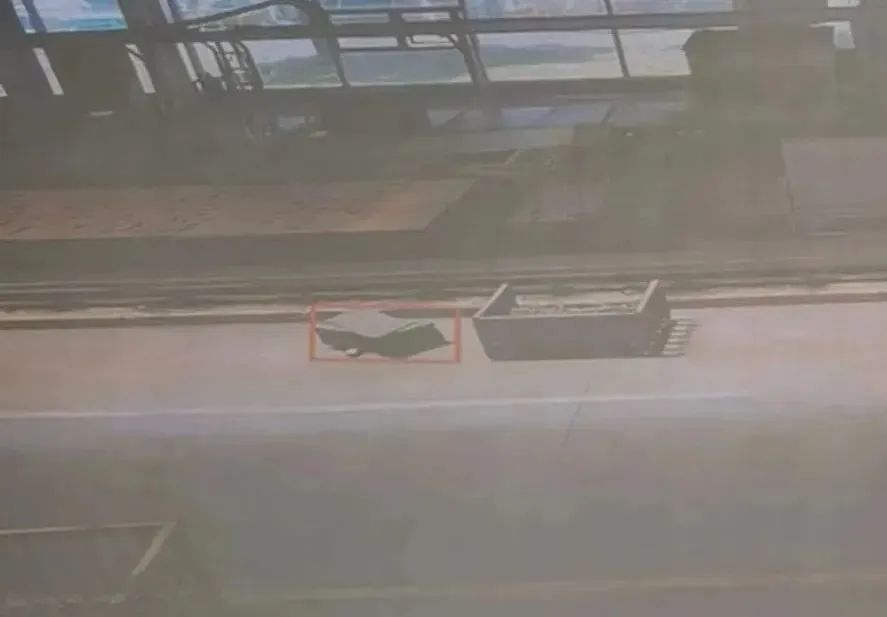

There are nearly 2,000 cameras in the factory to help managers understand the scene, the real thing, and the reality of each place—what Sany calls "Three Presents". If a person does not operate properly, or even put a piece of clothing in a place where it should not appear, it will be recognized and reminded by the system. In fact, you can see the real-time situation of Sany's factories across the country from the large screen, and the camera will automatically capture all non-compliant behaviors, such as materials not being stacked neatly, even if the top piece of a stack of steel plates is slightly tilted.

In addition, there are hundreds of industrial robots one after another, hundreds of AGVs to transport accessories, industrial workers do not need to learn to screw, but to learn programming.

"It's even less than our factory." The head of an enterprise that supplies parts to Sany lamented.

02Intensive capital investment

"That's a lot of money, it's a lot of money." One of the students repeated this sentence repeatedly.

After all, everything that happened in the huge steel structure factory is too shocking, and behind the intelligent manufacturing is the investment courage of billions. The mentor also responded at the review meeting that the future of China's manufacturing industry will inevitably be an industry with intensive capital investment.

03Garden plant

The mechanical arm of the production line is set against the dusty ground - it is really dusty, and Sany has an obsession with this, thinking that if it can't even be tidy, then precision is impossible to talk about.

There are also huge greenery and swimming fish pools in the factory to relax the body and mind of employees.

Some students also mentioned that the slogans of Sany Heavy Industry are particularly large, such as "Be grateful" and "Work hard to realize the Chinese dream", which are particularly eye-catching and inspiring.

This is a benchmark factory in China, and this is a Chinese factory that cannot be relocated to Southeast Asia.

04Excavator Index

Since 2014, Sany Heavy Industry has summarized the operation of nearly 800,000 excavators from its own factory, and now reports to the relevant ministries and commissions of the State Council every half month, which is the "excavator index" that can best reflect the operation of infrastructure and real estate across the country. The market share of the country has been the first in the country for ten consecutive years, and the market share in the world has been the first in the past two years, which is the confidence that they represent the entire industry.

In front of the excavator index display screen, which cannot be disclosed to the public, the trainees stayed for a long time, and everyone wanted to see the data of their hometown, "as if satisfying a desire to snoop".

05Either turn over or capsize

"Digital transformation is either turning over or overturning." This is a sentence from Liang Wengen, chairman of Sany Group, which was repeatedly mentioned in the venue and touched everyone.

It is necessary to be stable and far-reaching, and if you can't change the big era, you must do your best.

In addition, there are 257 accounts receivable turnover rate, parade-like rows of heavy trucks, and "real fragrance" staff canteens, all of which have become the memory points of the trainees' visit.

Of course, you can't skip the speeches of a few teachers and experts, and the minibus has sorted out the essence of it and shared it with you.

He Dongdong

Co-founder and CEO of Tree Root Internet

Let's imagine the future of manufacturing.

First, the future manufacturing industry will definitely move from the physical world to the digital world, which can be like the consumer Internet, through the network to operate, make decisions, and issue execution instructions. It's even like playing a computer game, where your role in the background can make these offline machines execute instructions with unmistakable accuracy.

Second, there will be big changes in the way we see our business shape, just as we see changes in the sales model. The current factory, which is maintained by the management of power, will undergo a lot of changes. Platform-based organizations, networked manufacturing and services, and industrial knowledge accumulation will all come out.

Third, the widespread application of blockchain will allow us to automate our transactions. Transaction costs in the manufacturing industry are very high, but if blockchain technology can be combined with IoT, transactions can be automated.

Fourth, the integration of production capacity. All of you here may often receive phone calls asking if you want a loan, because your consumption digital model and credit model have been established, and financial institutions can give you a loan. But it is very difficult for a serious manufacturing company to get a loan. Why can't the value of venture capital in manufacturing be loaned at any time? The difference is that its entire production cooperation does not have a digital model and a real-time credit model.

However, after the addition of IoT statistics, all your production behaviors can be profiled, our manufacturing enterprises are likely to borrow very accurately anytime and anywhere, which can also solve a very big problem in our manufacturing industry, that is, the difficulty of financing.

To sum up, the system of intelligent manufacturing is a networked real-time dynamic system. At that time, the boundaries of the factory will be broken, and if I want to devote myself to manufacturing entrepreneurship, I may not have to buy a factory or a machine by myself, I can find the right machine and a suitable factory online to help me produce.

Based on this vision of the future, the digital transformation of industry will definitely bring several needs.

The first is external interconnection. I have to connect all the machines, materials, and materials.

Second, two data sources - a large amount of IoT data and Internet data to be processed, are no longer the structured data in the information system of the traditional manufacturing industry. So there are two big data sources.

The third is the introduction of new technologies. I just talked about the digitalization of our manufacturing industry, which is essentially the introduction of Internet technology into the manufacturing industry. But with so many new technologies on the Internet, which manufacturing company can keep up? It certainly can't keep up. So, we need to have a platform to turn these new technologies into some easy-to-use applications.

Fourth, one of the most important application directions of industrial App 4.0 is data-driven applications, which are massive applications. Every part of my equipment can be made into an operator and an algorithm model to express its process. It's just a separate app, and it's constantly learning. Think about it, how many such apps will there be? In the field of marketing, where to produce these massive apps and how to tackle key problems? This is a very new need.

Fifth, platform-based industrial chain. The industrial Internet platform wants to optimize and split the orders of a large number of factories, which is a change in the business model.

Sixth, the industrial Internet platform. From the perspective of demand, all these new connection objects, new data sources, new applications, ERP, the most important industrial software in the 3.0 era, which one can meet so many needs? We can't meet it, so we need a new architecture, the industrial Internet platform.

Just like now, each of our mobile phones has been fully interconnected, but it does not mean that the mobile phones are directly interconnected one-to-one, but connected to the operator's platform, and then the operator makes the most efficient connection.

Seventh, data specification. We need to have some data specifications and data models that can converge the diversification of the manufacturing industry so that our information technology can deal with it, rather than everyone building their own data twins, and there will definitely be some specifications that everyone recognizes.

Liu Yan

Senior Deputy General Manager of Sany Heavy Industry

Deputy Director of Intelligent Manufacturing Headquarters and President of Intelligent Manufacturing Research Institute

The industrial brain of Sany Digital, as a whole, is at the leading level of the global heavy industry industry.

First, automatic scheduling. Through automatic scheduling to workstations in the system, the accuracy rate of online planning can reach more than 95%;

Second, the computer automatically issues production tasks, and basically realizes the unmanned mobilization of production tasks;

Third, the use of central control automatic work reporting, automatic reporting rate of more than 50%, including non-lighthouse projects, if the removal of only lighthouse factories, this data will be higher.

Fourth, the wages of front-line workers are paid on a daily basis, although in actual operation it may not necessarily be paid daily, but the daily wages are paid daily, so that we can know the working hours and working status of each worker, which corresponds to his wages on the day;

Fifth, the perfect synergy between industrial software and hardware, and the distribution rate of AGV in the lighthouse factory line is 100%;

Sixth, promote the in-depth application of "on-site, real-life, and reality", equipment interconnection, energy, water, electricity, oil, and gas, 5G, and data, so as to achieve energy management, efficiency management, cost savings, and fault prediction.

We use data to support management decisions, including manufacturing dashboards, manufacturing system portraits, etc. Through the dashboard, we can clearly know what the status of our more than 100 work centers and dozens of storage centers is running, which efficiency is relatively high, which efficiency may need to be improved, which costs may exceed the standard, and which equipment needs to be maintained.

Just now, an entrepreneur said that when he visited the Sany factory, all he saw was money (investment). I think it's right, investment is necessary, but on the other hand, from traditional manufacturing to intelligent manufacturing, it is more important to make a strategic choice, where to invest money and resources? How do we respond to changes in the structure of the workforce, cope with the pressure of rising raw materials, and achieve higher production efficiency, shorter lead times, and greater returns. Therefore, intelligent manufacturing, with which it is coordinated, must be a transformation of the future business model. For example, when we visit a heavy truck factory, some people ask why we invest so much to build such a large production capacity? Because only with such a large production capacity, it can establish an agile model to deal with the Internet sales model of heavy trucks, and can achieve C2M (user-connected manufacturing).

Therefore, the essence of the digital transformation of traditional enterprises is the transformation of the business model, and the transformation of the business model must be supported by a strong manufacturing capability and a digital system to support its manufacturing flexibility, the stability of its supply chain, and its overall online marketing.

The future is the era of software-defined everything, all the world's top 500 companies will be software companies, and the bottleneck problem of China's manufacturing industry will also change from precision mechanical parts to chips and industrial software. Sany has initially realized the intelligent manufacturing system, and our subsequent planning in the field of intelligent manufacturing focuses on the autonomy of industrial software and in-depth mining of data applications and data intelligence.

In addition, Sany has collected all the data, but the use of data needs to be improved. But I think it's only a matter of time, and doing real data recording and collection is the first step to achieving intelligence. By the way, I would like to share an experience with you, don't collect a lot of data because you don't know how to use it now, because many data cross-application scenarios are not something that can be thought of when collecting. When the data accumulates to a certain extent, and then you go back to process optimization, quality analysis, consumer insight, and product improvement, you will find that the more dimensions of the data, the more detailed and real the data record, the greater the value of the data.

Wu Xiaobo

Financial Writer

How to distinguish between Japanese factories and European and American factories? There is a very simple way, the production team of the Japanese factory has a blackboard with everyone's name written on it. Once I saw a few circles drawn on the ground in front of the blackboard, and no classmates knew what it was for. They told me that every day before getting off work, colleagues from this production group would come here for a small regular meeting, and everyone would put forward their opinions, and whoever put forward more opinions would be selected from the excellent employee of the day. This excellent employee stood in the circle, and the other employees stood next to him and applauded.

That's a good organization for amoeba learning. When we look at factories, we also have to learn to learn.

Over the years, I have often said that we must have the ability to learn, and our enterprise must also become a learning organization. I found that there is a big difference between the learning ability of entrepreneurs and the learning ability of students in other industries. We entrepreneurs may not have the best academic qualifications, right, but many of our entrepreneurs are still able to maintain a good job, because we usually have a particularly important ability - to draw inferences.

Our learning may not necessarily be learning from books or teachers, but learning by doing. Our visit to the factory is a kind of practice, so after the visit, we ask questions, review and discuss together, which is also practice and learning.

In today's Chinese factories, in fact, it is rare to see an all-round champion, generally in some aspects, in some fields, with their own outstanding characteristics and practical experience. We must prepare in advance, be good at observing, and be able to highlight key points and ask questions, so that our visit will be more effective.

Rail-mounted container gantry crane automation

Rail-mounted container gantry craneRecommended products

0 comments