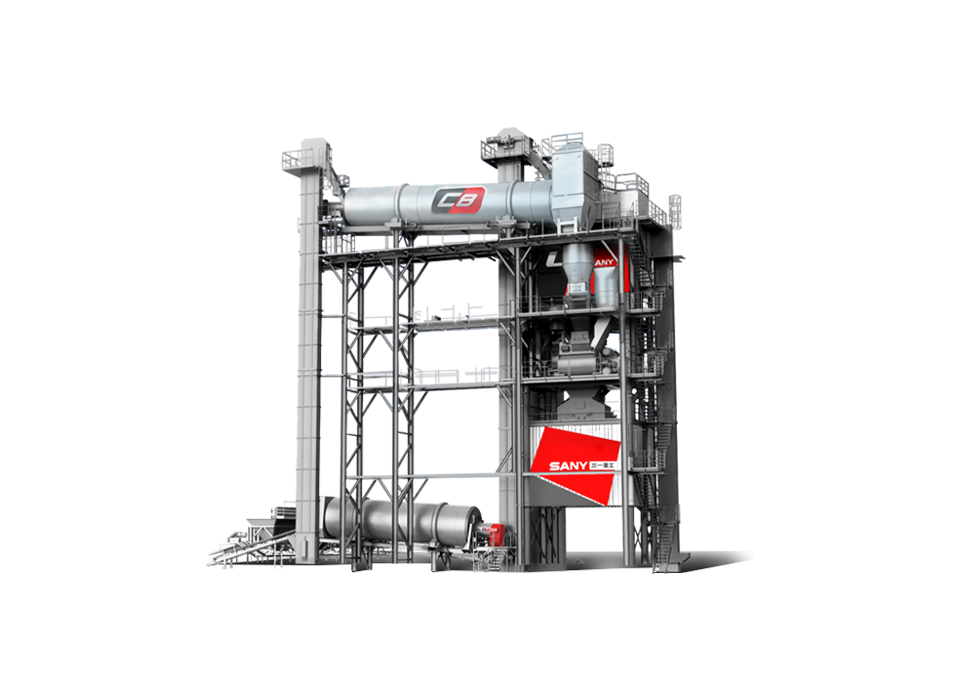

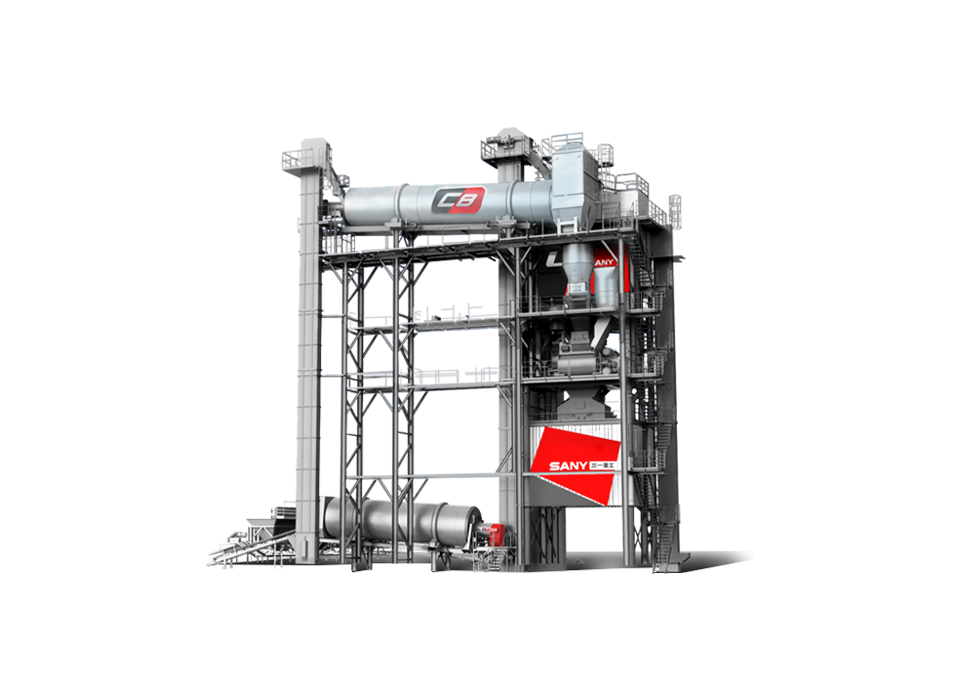

Efficient, intelligent and environmentally friendly, Sany C8 asphalt mixing plant is so "* can"

2017.03.17

From the research and development of *5656 sets of asphalt mixing plants in 2006 to the fifth generation of environmentally friendly asphalt mixing plants in 2015 sold all over the world, from half of the plant in Changsha Industrial Park to "Changde Sany" Industrial Park, Sany has spent less than 10 years to make the asphalt mixing plant become a star product with market sales of *5656 for three consecutive years, and the product quality and performance have been recognized by the majority of customers.

As one of the earliest manufacturers involved in the field of asphalt mixing in China, the precipitation of time has already made Sany a leader in the industry leading the rapid development of the asphalt mixing field. At the beginning of 2017, Sany once again launched its new generation of C8 asphalt mixing equipment series products for the pain points of the industry.

To create value for customers as their own responsibility

Adhering to the historical mission of "quality changes the world" and taking "creating *5655 value for customers" as its own responsibility, Sany has set up the American Research Institute of Sanyi Machinery and the German Research Institute of Sanyi Machine, and the products integrate the world's leading technology, and the asphalt mixing plant has won the domestic sales volume of *5656 for five consecutive years, which is the *5656 brand in China and sells well in many countries around the world. As the L* brand of the domestic asphalt mixing industry, Sany is using its own development practice to play a leading role model for the transformation and upgrading of the industry, and to solve the shortcomings of the industry.

"The characteristics of Sany C8 asphalt mixing series include high efficiency, energy saving, environmental protection, safety and convenient management, etc., which are the product design of Sany for the shortcomings of the industry." Liu Dongyu, project manager of Sanyi Road Asphalt Mixing Plant, said that the actual production capacity is not up to standard and the goal of zero pollution in the whole process of asphalt mixing has been people's dream for many years, and the starting point of the design of C8 series products comes from the actual needs of the market and customers, and the product performance is improved in a targeted manner, so as to meet or even exceed customer expectations.

High efficiency and energy saving at the same time

"The mixing efficiency has been increased to 260 tons per hour, and the efficiency of the whole machine is 16% higher than that of similar products." For the significant advantages of the C8 series products, Manager Liu Dongyu directly gave these two encouraging figures. "Many customers have reported that the production capacity of some domestic asphalt mixing plants is not up to standard, and we can proudly assure customers that the mixing efficiency of the C8 series has been significantly improved."

"In addition to a 16% increase in mixing efficiency, the high efficiency of the C8 series asphalt mixing plant is also reflected in its 15% capacity redundancy design, specially designed mixing host, and screening efficiency greater than or equal to 90%." Liu Dongyu said. In addition to high efficiency, C8 series asphalt mixing plants also have energy-saving advantages, including: small total installed power; The heat exchange rate of the drying drum is greater than or equal to 85%; The burner frequency conversion control technology is adopted, which saves 10% of fuel per ton of finished material; Asphalt rapid heating technology shortens the heating preparation time by nearly 1 hour.

Environmental protection first, green Sany

Sany C8 series asphalt mixing plant adopts dust-free cold material feeding technology, and mixes in the cold material system of asphalt mixture mixing plant and asphalt plantThermal regeneration equipmentThe integrated packaging structure is adopted at the recycling material supply system, especially for the cold material system of the asphalt mixture mixing equipment with prominent dust problems, an independent dust removal device is configured, and a dust extraction system is integrated in the packaging structure to ensure that the dust is "born" at the source and "stopped" at the source.

Sany C8 asphalt station adopts a distributed control system to seal the material channel, which can effectively solve the pollution problem. A number of environmental protection technologies such as wind and dust suppression, micro-mist dust reduction, plasma purification and process closure can effectively solve dust, flue gas and noise pollution, and finally make the exhaust emission concentration of asphalt mixing plant less than or equal to 20mg/nm, Ringelmann blackness less than or equal to level 1, and environmental noise 85dB (70dB of ear noise of operators in the control room). In addition, the main body of the asphalt station is a standard asphalt station + optional environmental protection facilities, which can be equipped with Sany LNG gasification station to provide fuel, reduce emissions, and add a touch of "green" to Sany asphalt mixing equipment.

Intelligent control and intelligent "manufacturing" Sany

"Another significant feature of Sany C8 series asphalt mixing plant is that it is convenient to manage, network data sharing can be realized between equipment, and the installation of GPS remote fault diagnosis system also brings convenience to users for later maintenance and use." Liu Dongyu said that the original intention of the development of this function was to remotely control the equipment for customers, and some customers even wanted to control the equipment through mobile phones. In the era of intelligent manufacturing, intelligent control is expected to be applied in traditional asphalt mixing plants.

According to reports, the C8 series asphalt mixing plant adopts Sany's unique intelligent control technology, based on the intelligent weighing of the user database of the neuron network, which can improve the batching accuracy of the asphalt mixture mixing equipment and the asphalt plant mixing hot recycling equipment through self-learning and database comparison, automatic weighing compensation, and automatic adjustment of batching parameters; The first intelligent production management system in China realizes remote online management of orders, production, sales and other business chains; The unique intelligent fault diagnosis system can detect the operation status of the equipment in real time, realize intelligent fault prediction, intelligent alarm and intelligent maintenance reminder, and make Sany "trinity" asphalt mixing plant become the "wise man" in asphalt mixing equipment.

At present, Sany C8 series asphalt mixing equipment 3000 and 4000 will be unveiled at the Sany Spring Ordering Fair, I believe that it will become a dazzling "star" in the asphalt mixing industry equipment at home and abroad in the near future, Sany C8 series asphalt mixing equipment is market-oriented, accumulates innovative strength, meets customer value needs, and climbs the industry's * 5661 peak.

Thermal Recycling Equipment SHR160C8

Thermal regeneration equipmentRecommended products

0 comments